5

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

This appliance is not designed to be operated in a negative pressure.

In very airtight homes with large kitchen exhaust fans, furnace cold air

returns, fresh air exchange systems and any other air system in close

proximity to the heating appliance may create a negative pressure in the

same room as the heating appliance. This can create dangerous back

drafting of the fireplace insert and chimney joints, drawing combustion

by-products into the home. Be sure your home has adequate makeup air

to eliminate negative pressures caused by the above-mentioned sources.

IHP accepts no liability for damages resulting from negative pressures

described above.

Ventilation Requirements - Provide adequate air for combustion. The

fresh air requirements of this appliance must be met within the space

where it will be installed. Ventilation is essential when using a Solid-Fuel-

Burning heater. In well insulated and weather tight homes, it may be

difficult to establish a good draft up the chimney (caused by a shortage

of air in the home). The lack of air is caused by many common household

appliances which exhaust air from the home (such as a furnace, heat

pump, air conditioner, clothes dryer, exhaust fans, fireplaces, and other

fuel burning appliances). Also, the combustion process of this heater

uses oxygen from inside the dwelling. If the available fresh air delivery

in the dwelling is insufficient to support the demands of these appliances,

problems can result (i.e. excessive negative pressure can develop in the

dwelling which will affect the rate at which this appliance can draft thus

resulting in performance problems. To correct this problem it may help

to open a window (preferably on the windward side of the house).

Whenever ashes get 3 to 4 inches deep in your firebox, and when the

fire has burned down and cooled, remove excess ashes. Leave an ash

bed approximately 1 inch deep on the firebox bottom to help maintain

a hot charcoal bed.

Ashes should be scooped out of a cool stove or fireplace insert with a

small metal shovel. Ashes should be placed in a steel container with a

tight fitting lid and moved outdoors immediately. Other waste shall not be

placed in this container. The closed container of ashes should be placed on

a non-combustible floor or on the ground, well away from all combustible

materials, pending final disposal. If the ashes are disposed of by burial in

soil or otherwise locally dispersed, they should be retained in the closed

container until all the cinders have thoroughly cooled. Ashes can ignite

up to 72 hours after removal from the fireplace insert.

When wood is burned slowly, it produces tar and other organic vapors,

which combine with expelled moisture to form creosote. The creosote

vapors condense in the relatively cool chimney flue of a slow-burning

fire. As a result, creosote residue accumulates on the flue lining. When

ignited, this creosote makes an extremely hot fire. The chimney and

chimney connector should be inspected at least once monthly during

the heating season to determine if a creosote buildup has occurred. If

creosote has accumulated (1/8” [3mm] or more), it should be removed

to reduce the risk of a chimney fire.

NEGATIVE PRESSURE WARNING

CREOSOTE, FORMATION AND NEED FOR REMOVAL

DISPOSAL OF ASHES

To pass inspection in nearly any jurisdiction, the chimney must meet both

safety and exhaust flow requirements. The (3’ by) 2’ by 10’ rule applies

to both masonry and factory-built chimneys.

* Ref. USA - National Standard, NFPA 211-latest edition and Canada

National Standard CSA B365-01-latest edition. Vents installed with a

listed cap shall terminate in accordance with the terms of the cap’s

listings.

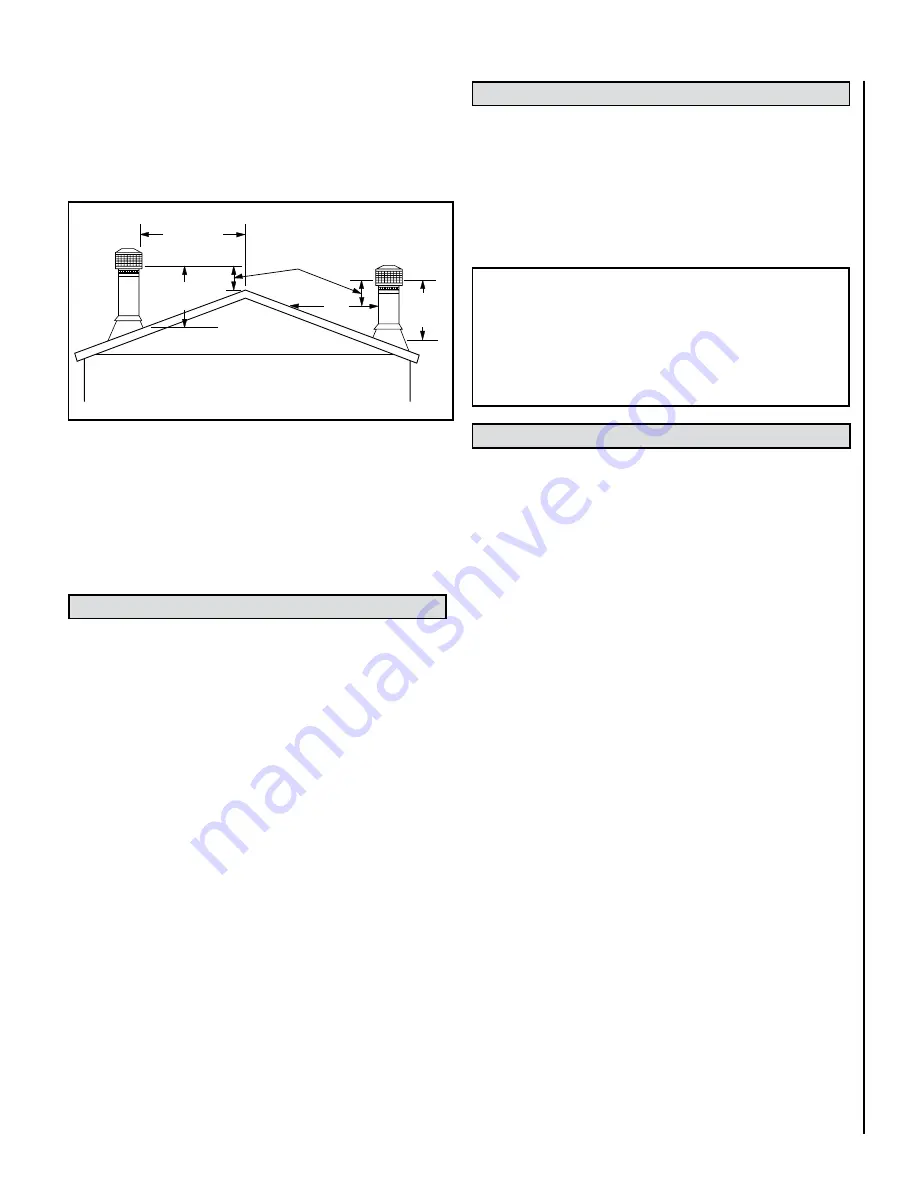

Figure 1

- Chimney Height Requirements

Less than

10' (3 m)

10'

(3 m)

3' (914 mm)

Min.

2’ (610 mm) Min.

(914 mm)

Min.

3'

Establish a routine for the fuel, wood burner and firing technique.

Check daily for creosote build-up until experience shows how often

you need to clean to be safe. Be aware that the hotter the fire the less

creosote is deposited, and weekly cleaning may be necessary in mild

weather even though monthly cleaning may be enough in the coldest

months. Contact your local municipal or provincial fire authority for

information on how to handle a chimney fire. Have a clearly understood

plan to handle a chimney fire.

Chimney Height Requirements

The chimney must extend 3’ (.92m) above the level of roof penetration

and a minimum of 2’ (.61m) higher than any roof surface within 10’

(3m) (see below). Check with your local building officials for additional

requirements for your area.