Facing

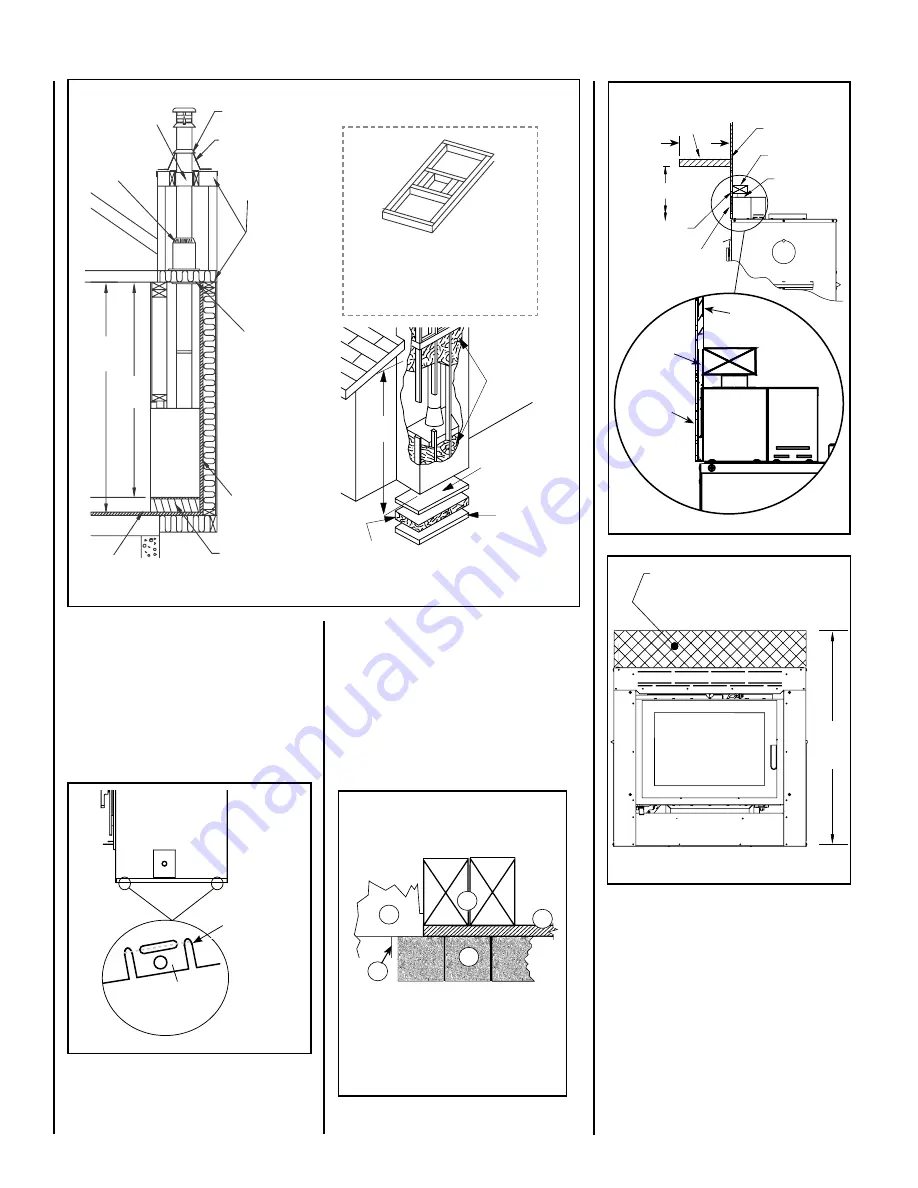

1. Combustible material must be installed

flush with the fireplace. It may not project

in front of and on the fireplace (i.e. the

steel facade of the fireplace)

(

Figure 19

)

.

2. Non-combustible materials such as brick,

stone or ceramic tile may project in front

of and onto the fireplace facing up to the

tiling flange

(

Figure 19

)

.

1

5

3

4

1. Fireplace

2. Tiling flange

3. Wood frame (2” x 3” min)

4. Drywall

5. Tiles or brick

Fireplace Frame Section

(Top View)

Figure 19

2

Nailing Flanges

Four nailing flanges are provided to secure the

fireplace to the floor

(see

Figure 18

)

. Bend

the nailing flanges down so that each flange is

flush with the floor, then using nails or screws,

secure the fireplace to the floor (2 places each

side). The heads of the screws or nails must

be large enough to completely cover the holes

in the nailing flanges.

Nailing Flange

(2 places each side)

Unbend to floor

and nail/screw

Mantel and Facing

The mantel must be installed at least 39’’ (990

mm) above the base of the fireplace

(

Figures

15 and 20

)

.

Fireplace Side

Figure 17

Figure 18

Insulated Chase Construction

7 Ft.

Min.

Attic

Radiation

Shield

Roof Support

Storm

Collar

Flashing

Drywall or

Any Rigid

Material

2” x 4”

1/2” Plywood

6’ 8”

Min.

Firestop

* Floor

Ceiling

Wall

* Floor

Ceiling

Wall

Fireplace

Insulate Joists

Same As Ceiling

Draft Stops

Firestop

CTDT

Termination

Note: Non-

Combustible

Chase

Flashing

Must Be

Used To

Cover

Chase

Opening

Optional

Insulation

In Outside

Walls Of

Chase

Solid

Continuous

Surface

Outside

Base

Insulation

(Thermal Barrier)

8'

Level

NOTE: It is recommend-

ed that the chase walls

and floor be insulated in

the same manner, using

the same insulation, as

the rest of the building,

below the attic.

• Must have the same firestopping

resistance as adjacent wall.

• Must have the same insulation as

adjacent ceiling.

• Follow local rules regarding fram-

ing construction.

SEE NOTE

7 Ft.

Min.

Attic

Radiation

Shield

Roof Support

Storm

Collar

Flashing

Drywall or

Any Rigid

Material

2” x 4”

1/2” Plywood

6’ 8”

Min.

Firestop

* Floor

Ceiling

Wall

* Floor

Ceiling

Wall

Fireplace

Figure 21

Only non-combustible mate-

rial should be superposed or

projecting over the front of

the fireplace.

38”

(965mm)

Min.

Figure 20

Mantel

Rock Board

or Other

Noncombustible

Facing

39’’ (990 mm)

Drywall

2 x 3 Min.

(51mm x 76mm)

Spacer

Mantel and Facing (Side View)

Rock Board

or Other

Noncombustible

Facing

Drywall

12”

(305mm)

Max.

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

16