24

25

The above details correspond as far as possible to the recommendations of the NAMUR working

party (NAMUR recommendations for the design of electrical plug connections for analogue and

digital signal transmission on individual items of laboratory control equipment, rev� 1�1)�

The NAMUR commands and the additional specific IKA commands serve only as low level com-

mands for communication between the device and the PC� With a suitable terminal or commu-

nications program these commands can be transmitted directly to the device� The IKA software

labworldsoft

®

, provides a convenient tool for controlling the device and collecting data under

MS Windows, and includes graphical entry features, for motor speed ramps for example�

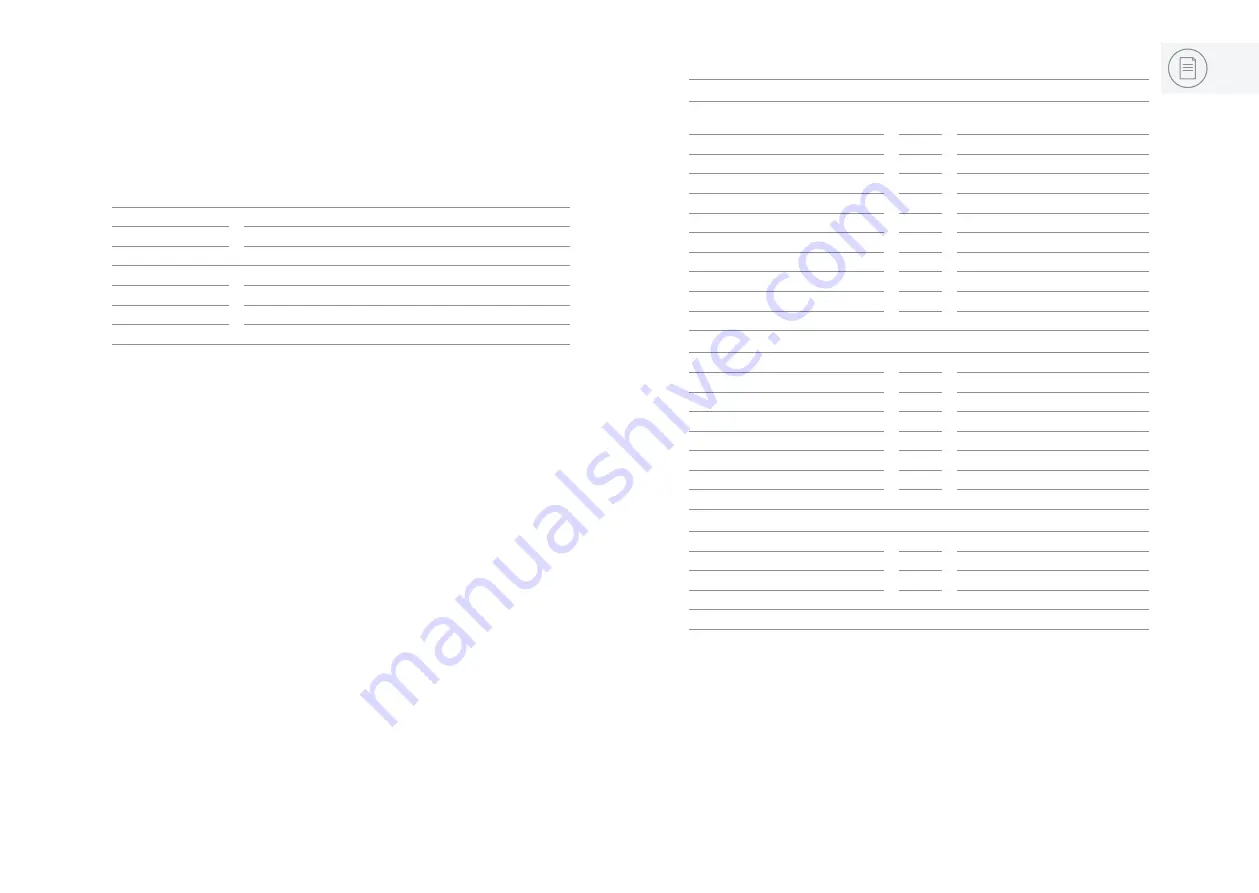

Commands

Function

IN_NAME

Read the device name

IN_PV_4

Read current speed value

IN_SP_4

Read rate speed value

OUT_SP_4 xxx

Change the speed value to xxx

START_4

Start the motor

STOP_4

Stop the motor

RESET

Switch to normal operation mode

Accessories

›

IKA MultiDrive BL 2000

blending vessel

›

IKA MultiDrive MI 250

milling vessel

›

IKA MultiDrive MI 400

milling vessel

See more accessories on

www.ika.com

�

Technical data

General data

Voltage

VAC

220 ��� 240 ± 10 %

100 ��� 120 ± 10 %

Frequency

Hz

50 / 60

Motor rating input

W

1000

Motor rating output

W

800

Interface

USB

Permissible ambient temperature

°C

+ 5 ��� + 40

Permissible relative humidity

%

80

Protection class according to DIN EN 60529

IP 31

Dimensions (W × D × H)

mm

300 × 250 × 450

Weight

kg

10

Operation at a terrestrial altitude

m

max� 2000

Grinding/blending function

Process type

batch

Short time operation (KB)

min�

5 / 10 (5 min� ON / 10 min� OFF)

Grinding methods

Cutting/impact

Speed range

rpm

3000 ��� 20000

Speed display

LED

Speed deviation

± 5 % of current speed

Speed setting

knob

Speed setting resolution

rpm

1 (x100)

Timer function

Timer range

0 / 1 seconds ��� 5 minutes

Timer display

LED

Timer setting

Button / knob

Timer setting resolution

sec�

1

Interval function

Yes (not adjustable)

Subject to technical changes!

Summary of Contents for MultiDrive basic

Page 1: ...IKA MultiDrive basic...

Page 2: ...3 ENGLISH...