9

max. 10 ˚

• Moving the device:

Empty all fluid in the bath before moving device from

one place to other place.

The device can be lifted up and moved by using the top

handles or the bottom handles (

12

, see

Fig. 1

).

It can also be moved on flat surface by lifting and push-

ing the front of the device. It is easy to move the device

with the help of the wheels.

The angle of inclination should never be more than 10 º

at any direction when move the device!

The device must not be moved

during operation. After moving

the device, you must wait at least

one hour before restarting the unit.

Fig. 10

NOTICE

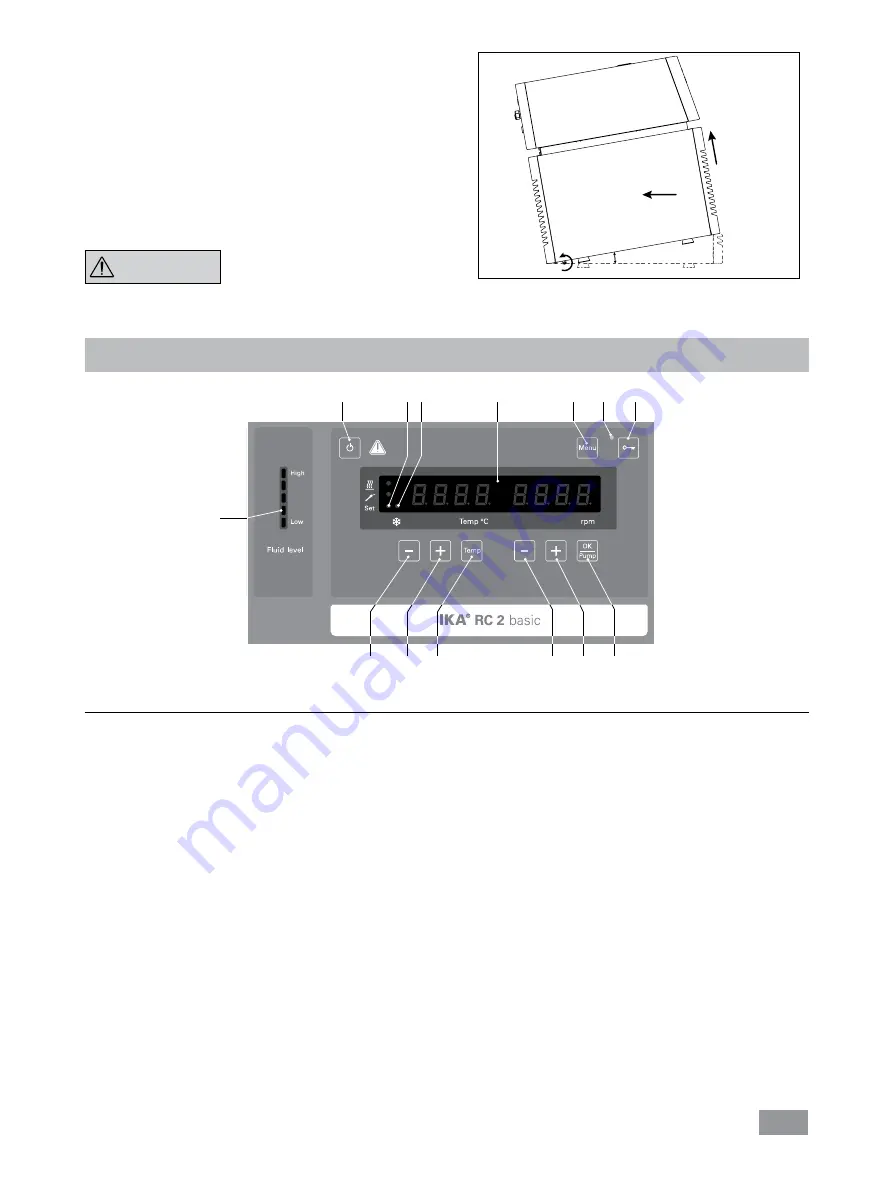

Operator panel and display

Item Designation

Function

A

ON/OFF button:

Switch on/off the circulator.

B

“Temp” button:

Start/stop the refrigerating function.

C

“Temp (+)” button:

Increase the temperature setting.

Navigation, selecting the settings in the menu.

D

“Temp (-)” button:

Decrease the temperature setting.

Navigation, selecting the settings in the menu.

E

“OK / Pump” button:

Start/stop the pump function.

Confirm the menu options.

F

“Pump (+)” button:

Increase the pump speed setting.

Change the menu value setting.

G

“Pump (-)” button:

Decrease the pump speed setting.

Change the menu value setting.

H

“Menu” button:

Press it once: menu option is display.

Press it once again: back to working screen.

I

Key button:

Lock/unlock keys.

J

LED, Key button:

Indicate the keys are deactivated.

K

LED display:

Display the settings and actual values.

L

Fluid level indicator:

Indicate the fluid level (when the fluid level is too low or too high, the bottom or the

top LED segment change into red color).

M

LED, cooling:

The light LED indicate the refrigerating function is activated.

O

LED, set:

The LED lights up at the same time as the set value is displayed.

A

B

F

G

H

I

E

C

D

K

L

J

O M

Fig. 11