14

Warnings concerning operation

-

Always handle the tool with care. Never play with the tool.

-

Always stand in balance. Do not use the tool on scaffoldings, ladders or on other unstable sur-

faces.

-

Never pull the trigger unless the nose is directed toward the work.

-

Keep others at a safe distance from the tool while it is in operation.

-

Never let children touch the tool. Only adults with experience or training to operating the tool

are allowed to use it.

-

The operator must not hold the trigger pulled on contact trip tools except during fastening op-

eration as serious injury could result if the trip accidentally contacted someone or something,

causing the tool to cycle.

-

Keep your hands and body away from the discharge area of the tool. A contact trip tool may

bounce from the recoil of driving a fastener and an unwanted second fastener may be driven.

-

Check operation of the contact trip mechanism frequently. Do not use the tool if the trip is not

working correctly as accidental driving of a fastener may result. Do not interfere with the proper

operation of the contact trip mechanism.

-

Do not drive nails on top of other nails or with the tool at an overly steep angle as this may

cause deflection of nails.

-

Do not drive nails close to the edge of the workpiece as the wood may split, allowing the nail to

be deflected and cause injury.

Follow all instructions and always note the warnings when using the tool. Use extra caution

when trying to solve tool problems.

OPERATION

Air supply

1.

Use only clean, dry and regulated compressed air at 5,5-7,5bar (80-110psi). Never use oxygen,

combustible gases or any other bottled gases as a power source for the tool as it may explode.

2.

Never exceed maximum or minimum pressure. Too low or too high pressure would cause noise,

fast-worn or misfiring. Refer to chapter ”Technical data” for setting the correct operating pres-

sure for the tool.

3.

When connecting air supply always keep hands and body from discharge area of tool.

4.

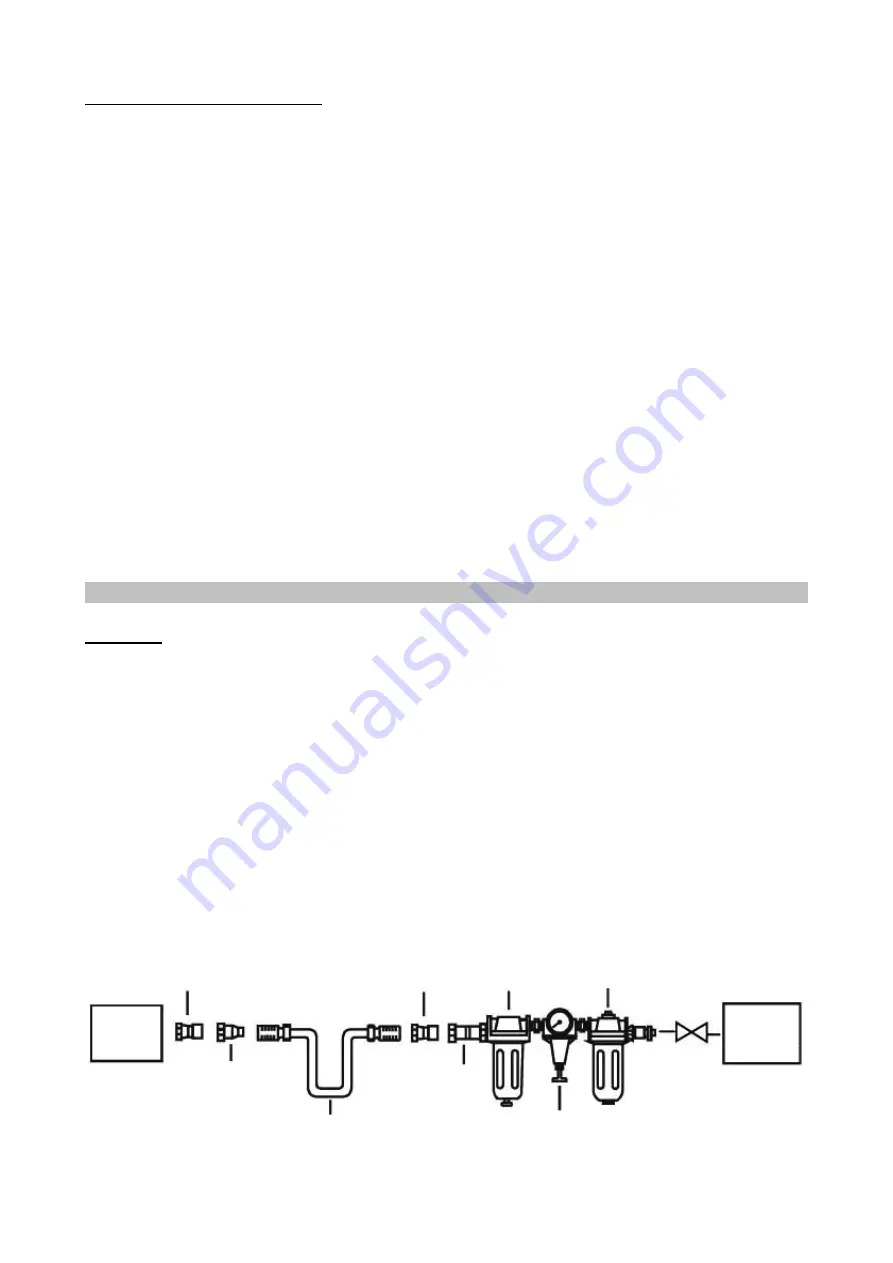

A filter-regulator-oiler system is required and should be located as close to tool as possible. (See

fig. 1)

5.

Keep air filter clean. A dirty filter will reduce the air pressure to the tool causing a reduction in

power and efficiency.

6.

For better performance, install a quick connector in your tool and quick coupler on the hose if

possible.

7.

Be sure all connections in air supply system are sealed to prevent air loss.

Fig. 1

Tool

Comp-

ressor

Lubricator

Quick

coupler

Quick

coupler

Cut-off

valve

Air hose

Regulator

Filter

Quick

connector

Quick

connector