INDEX

GUIDE TO THE MANUAL ......................................................................................................5

GENERAL INSTRUCTIONS ..................................................................................................6

1

TRANSPORT ..............................................................................................................7

1.1

Packing ............................................................................................................................ 7

1.2

Transport ......................................................................................................................... 7

1.3

Unpacking ....................................................................................................................... 7

1.4

Machine handling ............................................................................................................ 7

2

WORKING PARTS .....................................................................................................8

3

MACHINE DESCRIPTION ..........................................................................................9

3.1

Technical data ................................................................................................................. 9

3.2

Electrical circuit ............................................................................................................. 10

4

ACCESSORIES PROVIDED ....................................................................................11

5

MACHINE INSTALLATION AND PREPARATION ..................................................12

5.1

Checking for damage .................................................................................................... 12

5.2

Environmental conditions .............................................................................................. 12

5.3

Positioning ..................................................................................................................... 12

5.4

Description of work station ............................................................................................ 12

5.5

Graphics ........................................................................................................................ 13

5.6

Separate parts ............................................................................................................... 13

5.7

Connection to the mains ................................................................................................ 13

6

REGULATION AND USE OF THE MACHINE ..........................................................14

6.1

Setting ........................................................................................................................... 14

6.1.1

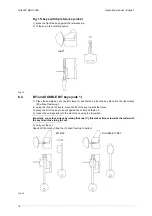

Adjusting the cutting depth ............................................................................... 14

6.1.2

Setting the cutting spaces ................................................................................ 15

6.1.3

Setting the cutting height .................................................................................. 15

6.2

Cutting operations ......................................................................................................... 16

6.3

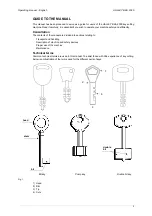

Key cutting ..................................................................................................................... 16

6.4

BIT and DOUBLE BIT keys (side 1) .............................................................................. 18

6.5

Pump keys (side1) ......................................................................................................... 19

7

MAINTENANCE ........................................................................................................20

7.1

Cutting tool replacement ............................................................................................... 20

7.2

Tracer point replacement .............................................................................................. 20

7.3

Replacing the fuses ....................................................................................................... 21

8

DISPOSING OF MACHINE .......................................................................................22

9

AFTER-SALES SERVICE ........................................................................................23

9.1

How to request service .................................................................................................. 23