HOW TO DUPLICATE KEYS

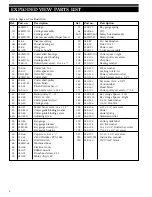

11

Aligning keys in the vise jaws

Keys without shoulders

On keys such as the Ford double-sided key, which do

not have a conventional shoulder, the tip of the key is

used as the aligning point (see Fig. 4). Clamp the blank

key in first and move the machine carriage to the left.

Lower the key gauge and position the carriage so the tip

of the Ford key touches the key gauge. Install and align

the pattern key in the left vise jaw in the same manner.

“Best” and “Falcon” type keys do not have a conven-

tional shoulder but have a recessed tip and the key

gauge is used to align the recessed tips. After clamping

the blank key, the carriage is moved to the left so that the

key gauge can be lowered to contact the recessed tip sur-

face. The pattern key is aligned in the left vise jaw and

positioned to contact the edge of the key gauge in the

same manner.

Aligning keys in the vise jaws

Keys with shoulders

WARNING: Do not install or remove keys unless

the off/on switch is in the off position.

Both the pattern key and the key blank must be properly

aligned and securely clamped in the vise jaws. To do this,

slide the machine‘s carriage assembly towards the right and

position the appropriate key blank in the carriage’s RIGHT

vise jaw with the head of the blank pointing to the left.

Ensure that the shoulder of the key blank is located

approximately

1

⁄

8

” to the left of the vise jaw‘s left edge.

Holding the key blank firmly and level against the jaw,

tighten the wing nut. Position the pattern key in the car-

riage‘s LEFT vise jaw in a similar manner only this time

allowing a

1

⁄

4

” gap between the shoulder of the key and

the edge of the vise jaw.

Next lower the key gauge and position the carriage so

that the left edge of the gauge’s RIGHT prong contacts

the edge of the key blank’s shoulder (see Figure 3).

Loosen the wing nut securing the pattern key and repo-

sition the key so that its shoulder is in contact with the

left edge of the LEFT prong of the key gauge.

Check to ensure that the pattern key and blank

key‘s shoulders are snug against the key gauge and

both keys are positioned level (not tilted) in the

vise jaws. Retighten the wing nut.

Figure 3

Aligning shoulders of keys with key gauge

Figure 4

Use of gauge with various key types

Shoulder

Tip

Recessed tip