ADJUSTMENTS

13

Adjusting for depth of cut

To ensure safety, UNPLUG machine from its power

source before adjusting for depth of cut. It's imperative

that the key guide and the cutter be in the same plane,

that is, aligned to each other. If the cutter guide protrudes

further than the cutter, the resulting cuts in a key blank

will be too shallow and the duplicate key will not work.

Likewise, if the cutter guide is behind the cutter, the cuts

in the key will be too deep (see Fig. 6).

To check the depth adjustment, insert two identical key

blanks into the vise jaws, setting them flat in each vise.

(It is not necessary to align the blanks.) Then, raise the

carriage, positioning the left blank against the cutter

guide and the right blank against the cutter. Next, turn

the machine pulley by hand and note the right key blank.

The cutter should just barely graze the key blank when

the adjustment is correct.

No cutter is perfectly round so make one complete rota-

tion of the cutter before changing adjustment. There will

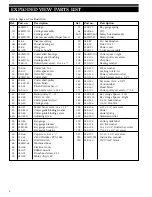

Figure 6

Depth Adjustment

Dial

Binding

screw

Adjustment is

correct when

both key blanks

touch

Figure 7

Carriage stop

adjusting screw

be a high point on the cutter; the adjustment should be

made to the high point. If the cutter does not touch the

key blank after one rotation, proceed to change the ad-

justment.

To adjust the cutter guide,

loosen the binding screw

on top of the cutter guide

slightly

. (see Fig. 7 & 8).

Once you have loosened

this screw, the depth

adjustment dial can be

rotated to the left (to

decrease depth of cut) or

to the right (to increase

depth of cut). Again,

proper adjustment will be

achieved when the cutter

just

barely grazes

the key blank before it while the cut-

ter guide is in contact with the other key blank. Retighten

the binding screw once the calibration process is com-

pleted. Recheck after tightening to assure that adjust-

ment did not shift.

Each calibration mark on the depth adjustment dial is

equivalent to approx. .0015” (1 1/2 thousandths of an

inch). As you can see, this system can allow for very pre-

cise adjustment of your new key machine. In fact, if you

have a key micrometer or dial caliper available, you can

adjust your machine with “factory accuracy”. To do this,

you would simply duplicate a key and measure cuts on

both the “pattern key” and the duplicate key for com-

parison. This would show any deviation that existed and

whether the duplicate cuts were too deep or too shallow

and by how much. With this information, you can use

the depth adjustment dial on your machine to calibrate

your machine for best possible accuracy. This is very

important as many locks are designed with close fit tol-

erances and the keys you duplicate are often themselves

copies; functional but just barely so. The more accurate

your key machine is adjusted, the closer your duplicates

will match their originals, resulting in fewer non-func-

tional miscuts!

It is very important

to understand that adjusting your

machine is not a “one time” procedure. As the cutter on

your machine wears down, the machine must be adjust-

ed to compensate. It is good shop practice to

check

you

machines’ depth adjustment every 2-4 weeks, based

upon your store’s key cutting volume and readjust as

necessary. You will find that re-calibration is seldom

needed, but by checking and correcting

BEFORE

cus-

tomers begin returning miscut keys, you will create a rep-

utation for your store as a “good place” to have keys

duplicated.

Figure 8

Depth

Dial

Binding

Screw

Carriage

Stop

Binding

Plate