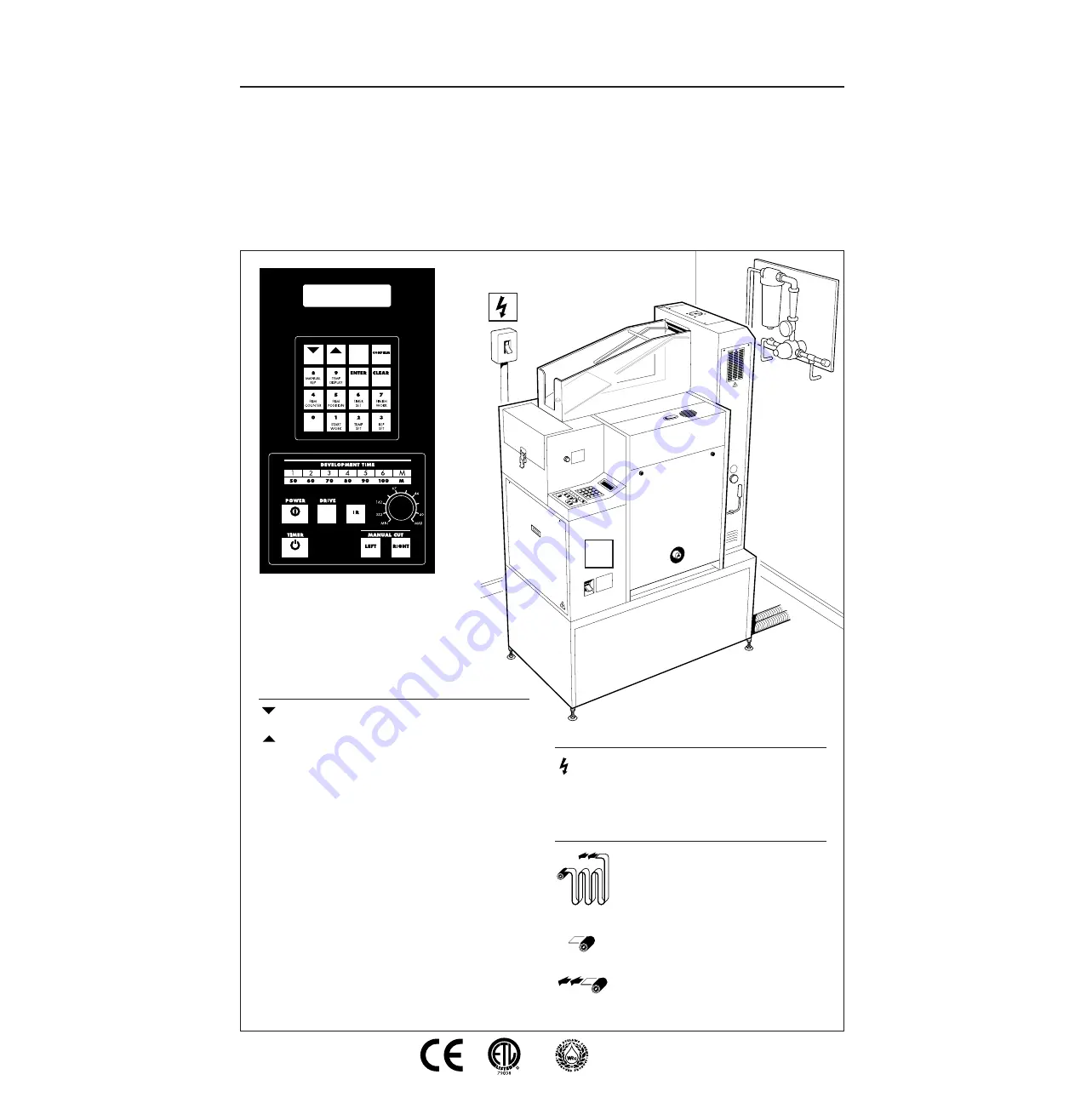

PROCESSOR

Mains isolator

I/O

Processor on/off switch

LABELS

IL793

I

0

ILF

OLAB FP40

ILFORD

ILFO

LAB FP40

50/60Hz

1st proof 14.12.95

OPERATING INFORMATION

ILFORD

ILFOLAB

FP40

The following symbols are used

to explain or highlight items or

actions that occur during use of

the ILFOLAB FP40 processor.

CONTROL PANEL

Forward through sequence

Back through sequence

ENTER

Record the new input data

CONFIRM

Verify the input data to memory

CLEAR

Clears the display, shows the

present state of the processor.

Press CLEAR at the start and end of

each programming sequence

POWER

Switches the processor systems on

DRIVE

Switches on drive motor, air pump

and dryer

TIMER

Select for automatic switch on

I/O

Film in processor

Orientation of cassette

Film in loading box