17

TB-CUT120CU-PS

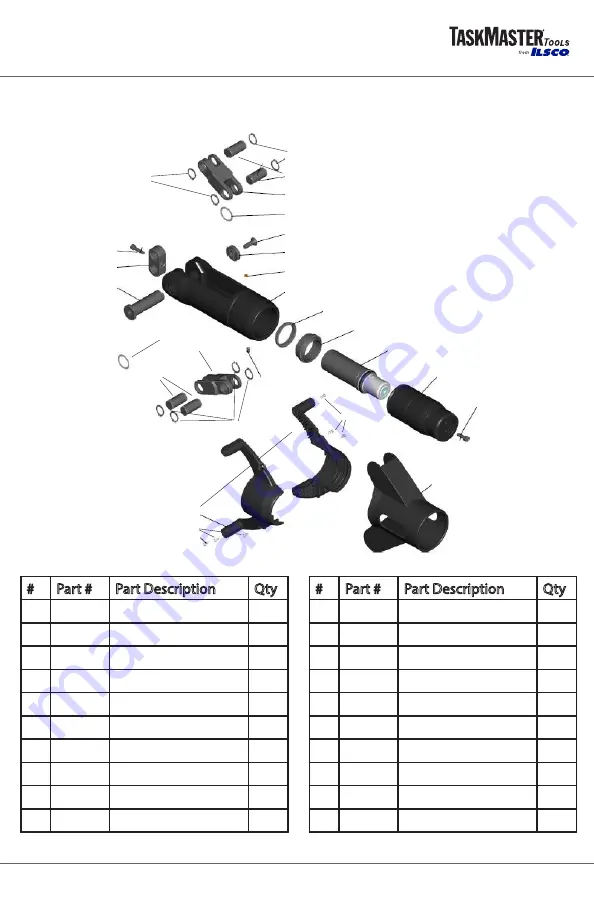

HEAD ASSEMBLY BREAKDOWN AND PARTS LIST

#

Part #

Part Description

Qty

1

200623 CAP SCREW

1

2

713738 BRIDGE

1

3

713741 BOLT

1

4

701008 GRUB SCREW

1

5

712882 HANDLE

2

6

100831 PT-SCREW

6

7

712903 PROTECTION

1

8

710710 CAP SCREW

1

9

712887 CYLINDER

1

10 713779 PISTON CPL

1

#

Part #

Part Description

Qty

11 713753 GUIDE BUSHING

1

12 712892 SCRAPER RING

1

13 713751 BODY

1

14 705806 FILTER DISC

1

15 713743 PRESSURE DISC

1

16 713748 SCREW

1

17 713752 SHIM RING

2

18 713736 PUSH ROD

2

19 713739 BOLT

4

20 700570 LOCKING RING

8

1

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

6

20

20

18

19

17

Summary of Contents for TASKMASTER TB-CUT120CU-PS

Page 20: ...20 TB CUT120CU PS Notes Notes ...

Page 21: ...21 TB CUT120CU PS Notes ...

Page 22: ...22 TB CUT120CU PS Notes ...

Page 23: ...23 TB CUT120CU PS Notes ...