INSTALLATION

2

2. ELECTRICAL CONNECTIONS

This equipment must be connected to a grounding plant.

Two types of electrical connection can be used:

1. Using a standard plug to be connected to the power

cable and inserted in a mains socket which must be

accessible (so that the plug can be disconnected when

servicing is carried out). Make sure that the plug is

accessible also after the complete installation of the

equipment.

2. By means of a fixed mains connection, fitting a

bipolar switch, which ensures the disconnection, with an

opening distance of the contacts allowing a complete

disconnection on the conditions of the over voltage III

category, according to installation regulations. The ground

connection (yellow-green wire) must not be interrupted.

Refer to the plate inside the hood for the mains voltage

and frequency ratings.

If the power cable is damaged, it must be replaced by the

manufacturer or by its service agent or a qualified person

in order to avoid any risk.

For stationary appliances permanently connected to

the fixed wiring, compliance with this requirement is

considered to be met if the instruction concerning

disconnection incorporated in the fixed wiring is in

accordance with AS/NZS 3000

Refer to the plate inside the hood for the mains voltage

and frequency ratings.

3. OPERATION

The hood is supplied with a multi speed motor.

The hood should be run at low speed under normal

conditions and at higher speeds only when there is a

heavy build-up of fumes or odour. Ideally, the hood should

be switched on as soon as cooking is started and then

kept on until all odour have been eliminated.

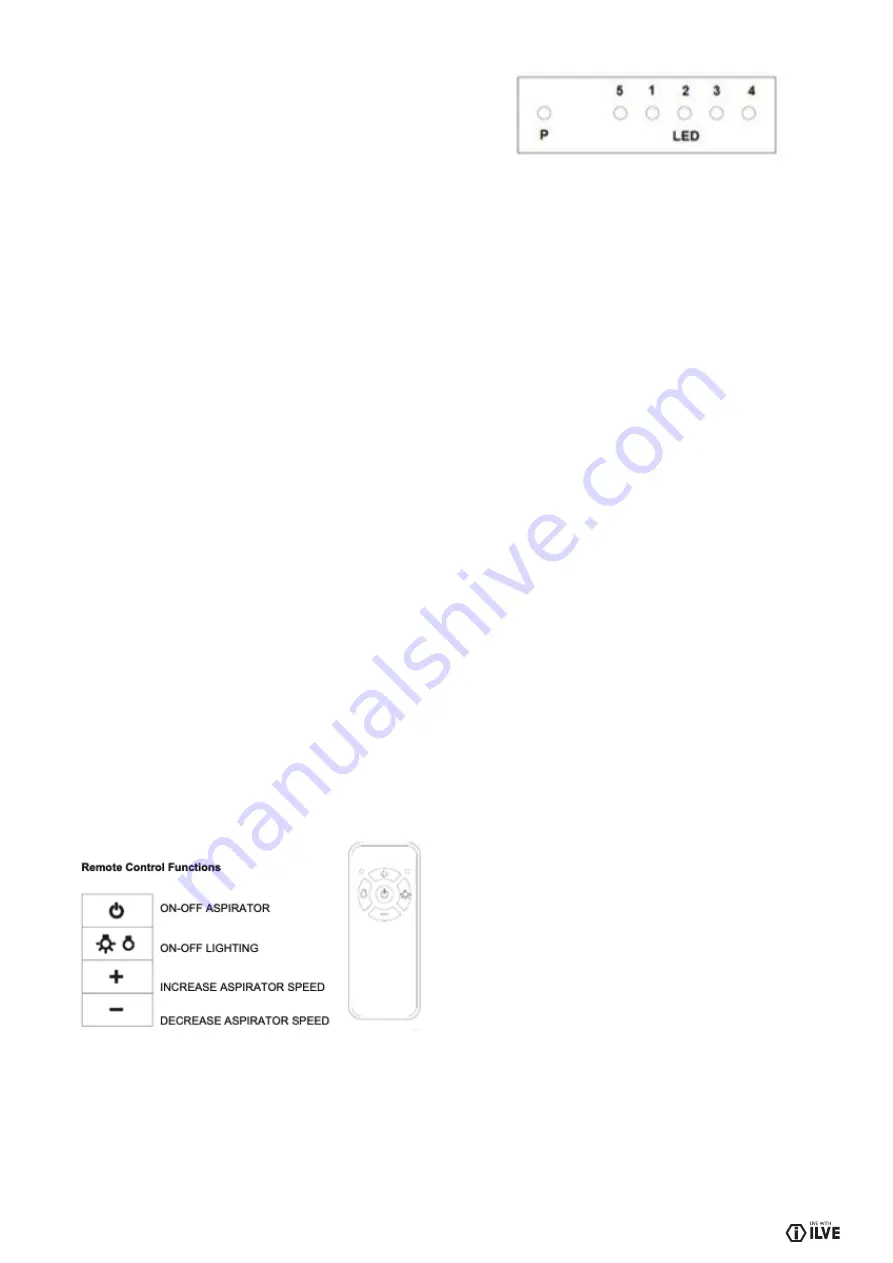

REMOTE CONTROL FUNCTIONS

When turned on, the engine is positioned at the second

speed. The motor speed is indicated by the lighting of

the respective green LED (ref. pos. 1-2-3-4). At the fourth

speed (intensive, ref. pos. 4), the LED flashes and after 5

minutes the motor returns to the third speed automatically.

REMOTE CONTROL ENCODING

The supplied remote control is already encoded and can

be used from the beginning for the total control of the

hood.

To encode another remote control, hold the button “P” on

the hood for 4 seconds until the programming red LED

lights up, at this point press immediately after the On / Off

aspirator.

When the red LED turns off, the programming is closed

and you cannot no longer program the remote control.

SAFETY SWITCH

In case the remote control is lost or out of batteries, the

appliance shall be switched off pushing the “P” button.

RESTORING FACTORY CONDITIONS (RESET)

Hold down the “P” button until the red LED lights up and

continue to press the button without releasing until the

LED turns off by itself. At this point no remote control will

be coupled and it will be necessary to pair one again.

GREASE FILTER MAINTENANCE WARNING

The electronic control report, after 100 hours of operation,

with the flashing of the LEDs, for 30 seconds at shutdown

of the hood, the need for cleaning of the grease filters.

To reset the counter, after cleaning the filters, while the

flashing warning press the “+” on the remote control until

shutdown.

5. MAINTENANCE AND REMINDERS

Always disconnect the hood from the mains before

carrying out any maintenance or cleaning operation.

Particular attention should be paid to the metallic anti-

grease filters that are designed to trap particles of fat

contained in the fumes. The metallic anti-grease filters

must be washed at least once a month with detergent in

hot water (or in the dish-washer). The filters may dis-colour

after a few washes. This is normal and does not mean

they have to be replaced. To remove the metallic anti-

grease filters, open the bottom panel of the hood and then

remove the filter by the handle. Fig. 17.

ATTENTION:

• the grease collected in the filter can easily catch fire

and it is therefore extremely important to clean the metallic

filter on a regular basis as per instructions. Grease filters

are removed as illustrated (Fig. 5).

• Do not flambé under the range hood

• Caution; accessible parts may become hot when used

with cooking appliances.

• Never leave the hob unattended when frying, as oil or

fat can catch fire.

The activated charcoal filters, if present, are designed to

collect unpleasant odour in the cooking fumes. The air is

Summary of Contents for CH900X

Page 1: ...INSTRUCTION MANUAL INSTRUCTION MANUAL CH900X CEILING HOOD CH900X CEILING HOOD ...

Page 2: ......

Page 7: ......

Page 8: ......

Page 12: ......