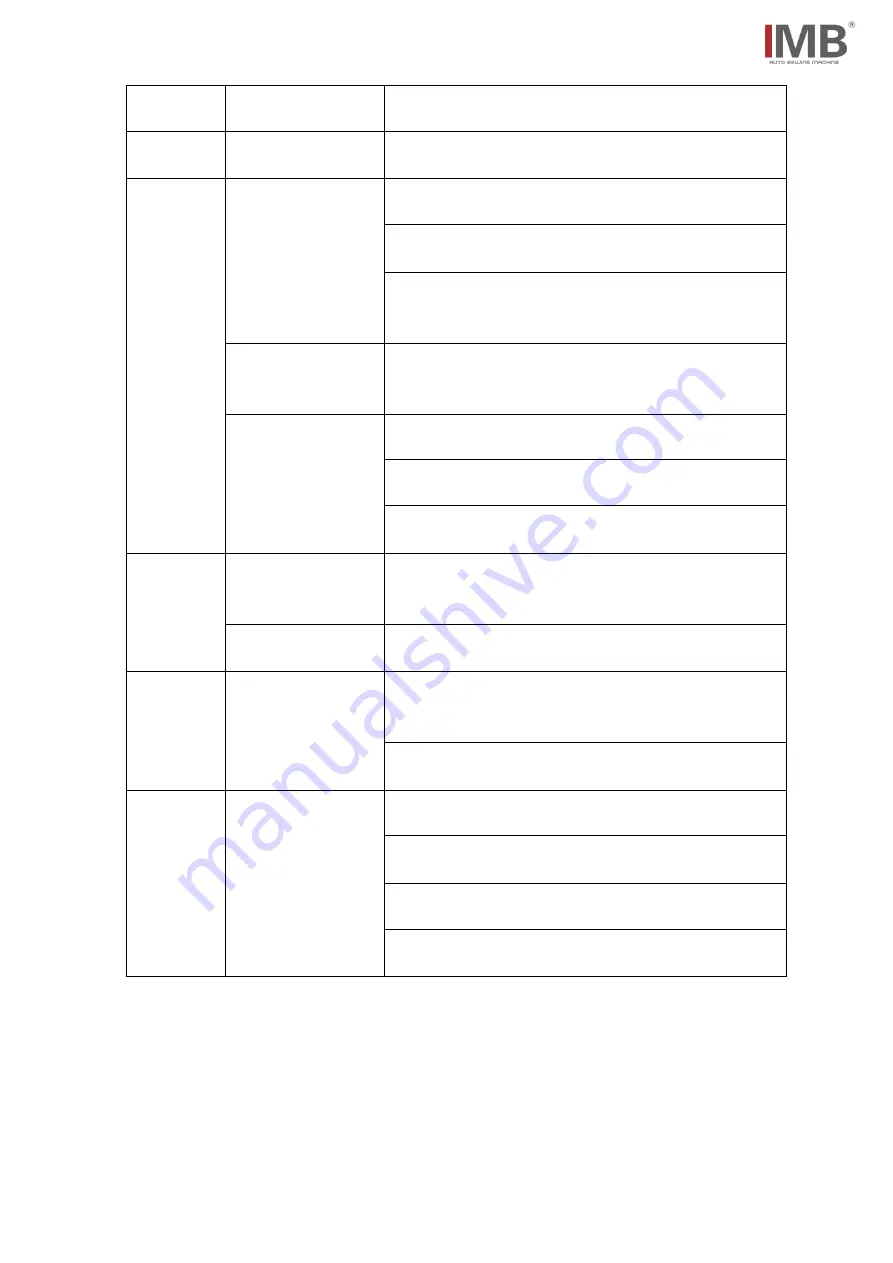

7

Button

Function / status

operation

Production

count

Record production

Click the "clear" button to clear

Automatic

sewing

ON-(cross

position

confirmation ON)

1、Step on the pedal to start sewing

2、The machine stops when cross position is

detected,

3、step on the foot pedal to continue sewing until

the end of sewing automatically, and lift up the

presser feet、Retract the

Stretch fabric group

ON-(cross

position

confirmation OFF)

(前)Step on the foot pedal to start the sewing

until the automatic end, and lift up the presser

feet、Retract the

Stretch fabric group

OFF

1、Long step on the pedal to sew

2、Release the pedal to end the sewing

3、(后)Step on the pedal to lift the presser foot、

Retract the

Stretch fabric group

Leg switch

ON

Cycle switch between left leg and right leg

(Subdivision of left and right foot patterns

improves sewing quality

OFF

Regardless of the left and right trouser legs,

Sewing in the same mode

Threading

Easy to thread

1、After clicking the "threading" button, press

the foot forward and backward to empty the

threading space

2、Click the "reset" button to lift the front and

rear presser feet

bobbin

thread

winding

bobbin thread

winding

1、Click the " bobbin thread winding " button

2、Put the winder in place

3、Long (front) pedal for bobbin thread winding

4、Release the pedal to end the bobbin thread

winding

4

.3 Emergency stop reset operation

1、After pressing the emergency stop button, the display will jump out of the emergency

stop dialog box

2、Emergency stop reset: first right turn the emergency stop button to make it pop up,

and then click the "reset" button on the display screen。

Summary of Contents for MB5004E-IM

Page 3: ......

Page 4: ...1 2 3 4 4 1 4 4 2 5 4 3 6 7 5 1 7 5 2 7 9 6 1 9 6 2 10 6 3 11 6 4 12 6 5 13 14 15 16 17...

Page 5: ...1 1 GC6770 2 3 4 5 6 7 8 9 10 11 12 2 3 1 4 5 6 11 9 8 10 7 12...

Page 7: ...3 1 1 2 V 3 4 5 6 7 8 9 10 11 12 13 14 A...

Page 8: ...4 4 1 1 90 ON 2 3 4 MB5004E IM 1 3 4 2...

Page 9: ...5 4 2 a b...

Page 10: ...6 ON ON 1 2 3 ON OFF OFF 1 2 3 ON OFF 1 2 1 2 3 4 4 3 1 2...

Page 11: ...7 5 1 5 2 5 2 1 90 ON 5 2 1...

Page 12: ...8 5 2 3 5 2 4 90 OFF...

Page 13: ...9 6 1 Mp 1 0 4 0 5 2 0 1 0 2 3 0 3 0 4 4 0 1 0 2 5 0 1 0 2 6 0 3 0 4...

Page 14: ...10 6 2 6 2 1 6 2 2...

Page 15: ...11 6 3 6 3 1 6 3 2 1 0 2mm 1 1 1 1...

Page 16: ...12 6 4 1 2 6 4 1 1 2 6 4 2 2...

Page 20: ...16 11 1 11 2 GC6770 C 1 2 3 4 5 6 7...

Page 21: ...17 MB5004E...

Page 22: ...ENGLISH...

Page 29: ...6 4 2 Operator interface description a Power on interface b Main interface...