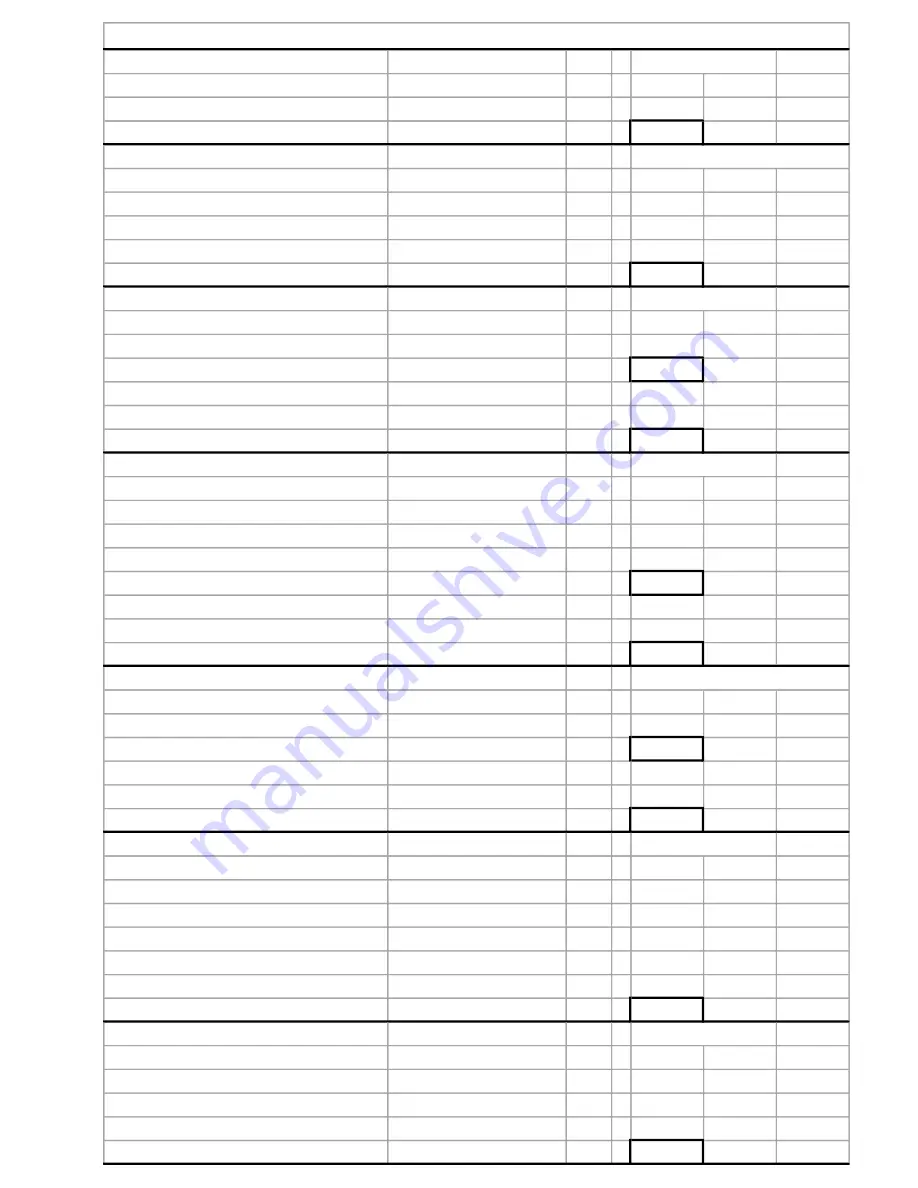

UPPER CAP

Parallels

2.250

Measurement

A

-

Norm

1.862

Cap Deck to Thrust Seat

Total

B

=

Norm

0.388

DECK TO PINION CENTERLINE

Deck to Tool

Measurement

C

Norm

2.252

Less Parallel

-

1.000

Total

Norm

1.252

Plus 1/2 tool

+

2.012

Deck to Pinion CL

Total

D

=

Norm

3.264

UPPER THRUST SEAT

Deck to Pinion CL

D

Norm

3.264

B

-

Norm

0.388

Pinion CL to Upper Thrust Seat

Total

E

=

Norm

2.876

Bearing Thickness

-

0.157

Mounting Distance

-

2.661

Race Thickness

F

=

Norm

0.060

LOWER THRUST SEAT

Measurement

G

Norm

7.138

Parallel

-

1.000

Deck to Lower Thrust Seat

Total

=

Norm

6.138

Deck to Pinion CL

D

-

Norm

3.262

Pinion CL to Lower Thrust Seat

Total

H

=

Norm

2.876

Bearing Thickness

-

0.157

Mounting Distance

-

2.661

Race Thickness

J

=

Norm

0.060

GEAR MEASURMENTS

Gear One

Measurement

K1

Norm

2.091

Less Parallel

-

1.000

Gear Depth One

Total

L

Norm

1.091

Gear Two

Measurement

K2

Norm

2.091

Less Parallel

1.000

Gear Depth Two

Total

M

=

Norm

1.091

GEAR ASSEMBLY

Gear Depth One

L

Norm

1.091

Gear Depth Two

M

+

Norm

1.091

Race Thickness

F

+

Norm

0.060

Race Thickness

J

+

Norm

0.060

2 x Bearing Thickness

+

0.314

Retainer Spacing

Measurement

N

+

Norm

3.162

Gear Assembly

Total

O

=

5.778

CAP CRUSH

Pinion CL to Upper Thrust Seat

E

+

Norm

2.876

Pinion CL to Lower Thrust Seat

H

+

Norm

2.876

Upper Thrust Seat to Lower Thrust Seat Total

P

=

Norm

5.752

Gear Assembly

Total

O

=

Norm

5.778

Cap Crush

=

Norm

.020-.030

SCX, SCX4 WORK SHEET Serial #

Page 9

Summary of Contents for Xtreme Advantage SCX

Page 6: ...Page 2 Upper Case Hardware Seals Fig 1...

Page 8: ...Upper Case Gear Components Fig 2 Page 4...

Page 12: ...Page 8 Page 8 SCX Setup Diagrams Fig 3...

Page 14: ...Backlash Assembly Fig 5 Page 10...

Page 16: ...Lower Gear Case Fig 6 Page 12...

Page 18: ...Lower Case Gear Fig 7 Page 14...

Page 20: ...Page 16 Lower Pinion Height Measurements Fig 8...

Page 23: ...Spline Seat Fig 9 Page 19...

Page 24: ...Running Load Page 20...