IMER INTERNATIONAL S.p.A.

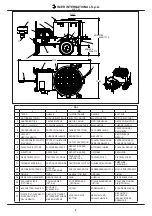

MIX 360

10

GB

Dear customer,

congratulations on your choice of purchase: the IMER cement mixer, the

result of years of experience, is a very reliable machine equipped with all

the latest technical innovations.

The machine can mix both dry or wet fi ne grain materials (plaster, mor-

tar, cement, fl oor sub-bases, rendering, synthetic resins or pre-packed

mixes).

WORKING IN SAFETY

In order to be able to work in complete safety, the following instruc-

tions must be read carefully

- This OPERATING AND MAINTENANCE manual must be kept on site

by the person responsible for the site, e.g. the SITE FOREMAN, and

must always be available for consultation.

- The manual should be considered as being an integral part of the

machine, and must be kept for future reference (EN 292/2) until the

machine itself is disposed of. If the manual becomes damaged or lost, a

replacement can be obtained from the manufacturer.

- The manual contains important information regarding the preparation

of the site, installation and use of the machine, maintenance and spare

parts ordering. Nevertheless, the installer and operator must both have

adequate experience and knowledge of the machine.

- In order that the safety of the operator, safe working and long life of

the equipment can all be guaranteed, the instructions in this manual

must be followed together with safety standards and health and safety

at work laws currently in force (use of suitable footwear and clothing,

use of helmets, gloves and goggles, etc. in accordance with S.I N° 3073

of 30/11/92.

. ALWAYS MAKE SURE THAT SIGNS ARE LEGIBLE

. It is strictly forbidden to carry out any form of modifi cation to

the structure or working parts of the machine.

IMER International decline any responsibility in the case of non-com-

pliance with laws and standards governing the use of this equipment. In

particular: improper use, defective power supply, lack of maintenance,

unauthorised modifi cations, partial or total failure to observe instructions

contained in this manual.

1. DESIGN STANDARDS

The MIX360 mixer has been designed and constructed in accordance

with the following standards:

IEC 34.1; IEC 34.5; EN292-1,EN292-2,EN60204-1.

2. NOISE EMISSION LEVEL

Table 2 indicates the noise level produced by the mixer, measured at

the operator’s ear (LpA at 1 m - 98/37CE) and the environmental noise

emission level (power LWA) measured in accordance with EN ISO 3744

(2000/14/CE).

TABLE 2

TYPE OF MOTOR

L

pA

(dB)

L

WA

(dB)

ELECTRIC

70

81

ENGINE 88

103

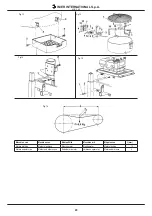

3. MIXING CAPACITY

The mixing capacity of the machine per cycle is 200 litres (approxima-

tely half of the tank height).

4. SAFETY MEASURES

-The IMER cement mixer can only function if all the safety devices with

which it is equipped are in perfect condition.

-The machine will not operate if the mains connection is defective.

-On-site power connection lines must be installed so that they cannot be

damaged. Do not stand the machine on the mains connection line.

-The power lines must be installed so that water cannot penetrate

connections. Only use connectors fi tted with protection against water

spray.

-Repairs to the electrical plant must only be carried out by specialised

personnel. Do not operate the mixer during maintenance or repair ope-

rations.

-Accident prevention and health and safety at work regulations must be

complied with in the working area.

. The machine must only be stopped using the appropriate

switch.

. Do not open the tank protection cover to stop the machine.

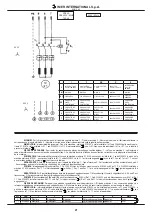

5. ELECTRICAL SAFETY

The IMER mixer complies with standards EN60204-1. In particular, it is

equipped with a system that prevents automatic restart after the power

supply line is interrupted.

-Residual current protection of electrical equipment

-Electrical safety device that prevents the machine from operating when

the tank protection cover is open.

When used on construction sites, the mixer can be connected to an

earthing system by attaching an earthing braid (or wire) of minimum

section 16 mm² (see Fig. 2).

6. MECHANICAL SAFETY

-A guard over the outlet prevents access to the mixing zone.

-The tank protection cover allows the mix components to be loaded

without access to the mixing zone.

The mixer will stop if the cover is opened.

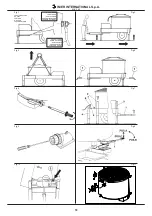

7. TRANSPORT

. WARNING!! Always disconnect the machine from the mains

before moving it.

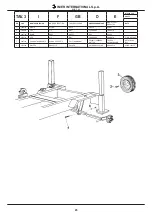

-When on-site, the mixer can be moved manually from one location to

another as shown in Fig. 3.

-For other types of handling, the mixer must be lifted using a four-cable

sling attached to the lifting lugs, as shown in Fig. 4.

8. INSTALLATION

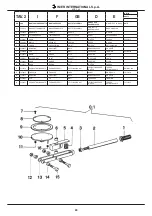

Lift the mixer (the mixer is fi tted with a lifting jack - ref. 4, fi g. 7).

- Screw in the outlet opening handle (see Fig. 6).

If there are no lifting means available, lift the mixer using the jack sup-

plied (see Fig. 7).

1 - Raise the rear supporting legs (Ref. 2 Fig. 7) to their maximum height

and lock them in position using the locking pins.

2 - Use the handle (Ref. 1 Fig. 7) to raise the machine, resting it on the

rear legs (Ref. 2 Fig. 7).

3 - Position the front legs (Ref. 3 Fig. 7) (towing side) at the height requi-

red and lock them using the locking pins.

4 - If the machine is to be positioned at maximum height, insert the lower

lug (Ref. 5 Fig. 7) in the support (Ref. 7 Fig. 7), raise and lock the rear

legs (Ref. 2 Fig. 7) at the third hole from the bottom.

5 - Remove the lower fork connection Ref. 5 and lower the jack so that

the upper fork connection can be inserted (Ref. 6 Fig. 7), then complete

the lifting operation.

For intermediate working levels, the rear part of the machine should

be lifted in a single operation, as in points 1 and 2, by using the lower

connection point on the jack (Ref. 5 Fig. 7).

To return the machine to the towing position, follow this procedure in

reverse order.

Position the machine on level ground, adjusting the telescopic legs to

the required height.

Ensure that the machine is in a stable working position.

9. USE

-Do not allow other people to remain in the vicinity of the machine during

operation.

-Do not use the machine in a fi re-risk zone. Sparks may cause fi res or

explosions.

-Always switch off the machine before leaving it unattended.

-The machine must only be transported or positioned with the motor

switched off.

9.1 START-UP

9.1.1 ELECTRICAL CONNECTION

-Check that the supply voltage is the same as dataplate specifi cations.

-Ensure that the power supply line is fi tted with a differential protection

device upstream.

-Connect the machine to the earthing plant and the mains power supply.

-Ensure that the blades rotate in a clockwise direction.

If the paddles rotate in an anti-clockwise direction, stop the machine, di-

sconnect the mains plug and invert one of the phases inside the plug, by

rotating the inverter slot between the pins using a screwdriver (Fig. 8).

- Start the motor by pressing the black on/off pushbutton on the control

panel.

9.1.2 ENDOTHERMIC MOTOR

-Check the motor (see motor manual).

-Check the motor oil level (see motor manual).

-Fill the fuel tank (see motor manual).

ORIGINAL

INSTRUCTIONS