IMER INTERNATIONAL S.p.A.

MIX 360

11

-Start the motor, following the instructions contained in the motor ma-

nual.

-Allow the motor to warm up at reduced rpm.

-Increase the rpm to maximum using the accelerator lever mounted on

the frame.

Machines with an endothermic motor are fi tted with a centrifugal expan-

ding clutch mounted on the motor.

The clutch enables the paddle rotation speed to be increased gradually,

which can be stopped when the motor is operating at minimum rpm.

Motor operating speed can be controlled by means of the accelerator

lever (rif. 5, tab. 9).

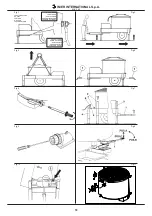

9.2 WORKING CYCLE

. WARNING! Check that the machine stops rotating when the

tank protection cover is lifted.

Start-up the machine with the tank empty.

-With the water supply connected to the mains, start feeding water by

opening the valve mounted on the tank, and add the cement and ag-

gregate.

-The tank protection grid is fi tted with a bag splitter to enable pre-packed

mixes to be used.

-When the mix has reached the required consistency, place a suitable

container under the outlet and, keeping the paddles moving, open the

outlet using lever Ref. 1 (see Fig. 9).

Lift the lever to position A and push it as far as possible to position B.

To close the outlet, return the lever to Pos. C.

. Avoid starting the machine with a full load.

Do not overfi ll the tank (see 3. MIXING CAPACITY).

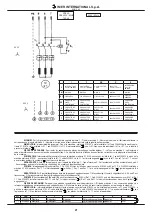

10. EMERGENCY STOP

. In the event an electric motor fault, press the OFF pushbutton

(Ref. 17 Fig. 1) and disconnect the mixer from the power supply.

In the case of endothermic motors, move the acceleration lever to

the minimun position.

. The motor is protected from thermal overloads. If it overheats

it will stop. It must be allowed to cool before restarting.

11. MAINTENANCE

. WARNING! Before carrying out any form of maintenance

work, always switch off the mixer.

-Replace worn or faulty components using original spare parts.

-Check the oil level through the transparent level indicator on the side of

the reduction gear casing.

-Change the oil in the reduction gear with SAE 90 oil after 2000 hours of

work (approximately 0.9 Kg).

-To top up or replace the oil, used the fi ller pipe (ref. 1, fi g. 10). Lift the

motor casing to gain access to the fi ller.

. Used oil is classifi ed as special waste and must be treated as

such in accordance with laws in force.

. Always ensure that writing and other instructions on the ma-

chine are legible.

. Always ensure that the protection devices are undamaged

and effi cient.

-At the end of the work session, remove dirt and/or any other deposits

formed during mixing by washing thoroughly (to wash the machine, use

the wash-water hose with pressure regulator, Ref. 51 Tav. 1, mounted

on the mixing tank valve).

. Check the condition of the power cable before using the machi-

ne; it may have become inadvertently or unknowingly damaged.

-Check the endothermic motor according to the instructions contained

in the motor manual.

If guards are removed due to maintenance requirements or other excep-

tional circumstances, proceed as described below, and always refi t the

guards before resuming operation.

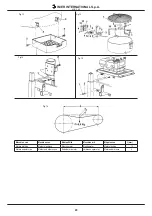

11.1 COVER PROTECTION ADJUSTMENT(FIG. 11)

The adjustment of the limit switch must be carried out with the tank

protection cover lowered.

Move the limit switch to the correct position using the slots and re-ti-

ghten the screws for disel engine.

The fi lling side cover grid opening is protected by a interlocked cut off

device that stops the engine as the protection cover is lifted, the adju-

stment is carried out by correcting the lenght of the wire and re-tighten

the screw.

. WARNING

Check that the machine stops when the tank protection cover is

lifted

11.2 OUTELET PROTECTION REMOVAL (Réf.Fig.12)

- Slacken screws Ref. 2 and remove protection Ref. 1.

- To replace the protection, align the holes with those of brackets Ref. 3

and tighten with screws Ref. 2. Use spanner N°13.

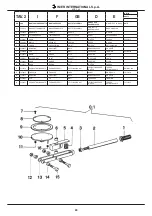

11.3 MIXING PADDLE REPLACEMENT (Fig.13)

- Lift the tank protection grid Ref. 1.

- Remove head protection Ref. 2, rotating it in an anti-clockwise direc-

tion.

- Slacken screws Ref. 3 and nuts Ref. 4. Use open-ended spanner N°17

and Allen key N*6.

- Remove the paddle clamps Ref. 5, 6 and 7 and replace the worn rub-

bers Ref. 8, 9 and 10. Inserting the new rubbers between holders Ref.

11, 12 and 13 and clamps Ref. 5, 6 and 7. Utilize the slots to adjust as

necessary and lock in position with nuts and bolts Ref. 3 and 4.

- Push arm Ref. 14 to manually rotate the paddles in a clockwise direc-

tion, checking the mating of the rubbers with the tank.

- If there are zones where the rubber is not in contact with the tank,

repeat the adjustment. Re-adjust utilizing the slots in brackets Ref. 15

and 16 if necessary.

- Replace and lock in position protection Ref. 2, rotating it in a clockwise

direction. Lower the cover grid Ref. 1.

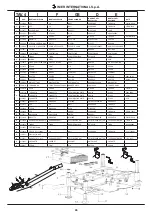

11.4 TENSIONING AND REPLACING TRANSMISSION BELTS

11.4.1 MIXERS FITTED WITH ELECTRIC MOTOR

(Fig.

14)

1. Unscrew the locking screws and lift the motor casing.

Use spanner N°6.

2. To tension the belts, slacken nut Ref. 1, tighten nut Ref. 2 and re-

tighten nut Ref.1. Use spanner N*19.

3. To replace the belts, slacken nut Ref. 23?? and nut Ref. 1, remove the

old belts. Replace them with new belts of same characteristics. Tension

as described in point 2.

4. Lower the casing and lock in position with the locking screws.

11.4.2 MIXERS FITTED WITH ENDOTHERMIC MOTORS

(Fig. 15)

1. Unscrew the locking screws and lift the motor casing. Use spanner

N°17.

2. To tension the belts, slacken nut Ref.1, tighten nut Ref.2 and re-ti-

ghten nut Ref.1.

3. To replace the belts, slacken nuts Ref.1 and Ref.2, remove the old

belts. Replace with new belts of same characteristics. Tension as de-

scribed in point 2.

4. Lower the casing and lock in position with the locking screws.

- Check the tension of the transmission belts after 4 hours from fi rst

start-up and after each belt change, otherwise check the tension every

18-20 hours.

. When replacing transmission belts, remember that a too tight

belt will cause damage to shafts and bearings, a too slack belt will

wear out rapidly.

11.4.3 REQUIREMENTS FOR CORRECT TRANSMISSION

BELT TENSIONING (Fig. 16)

To ensure correct tension of the transmission belts, apply a force “F”

(0.9 kg) on the centre of section “S”; distance “f” should be as specifi ed

in the table in Fig. 16.

GB