IMER INTERNATIONAL S.p.A.

MIX 360

12

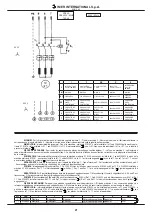

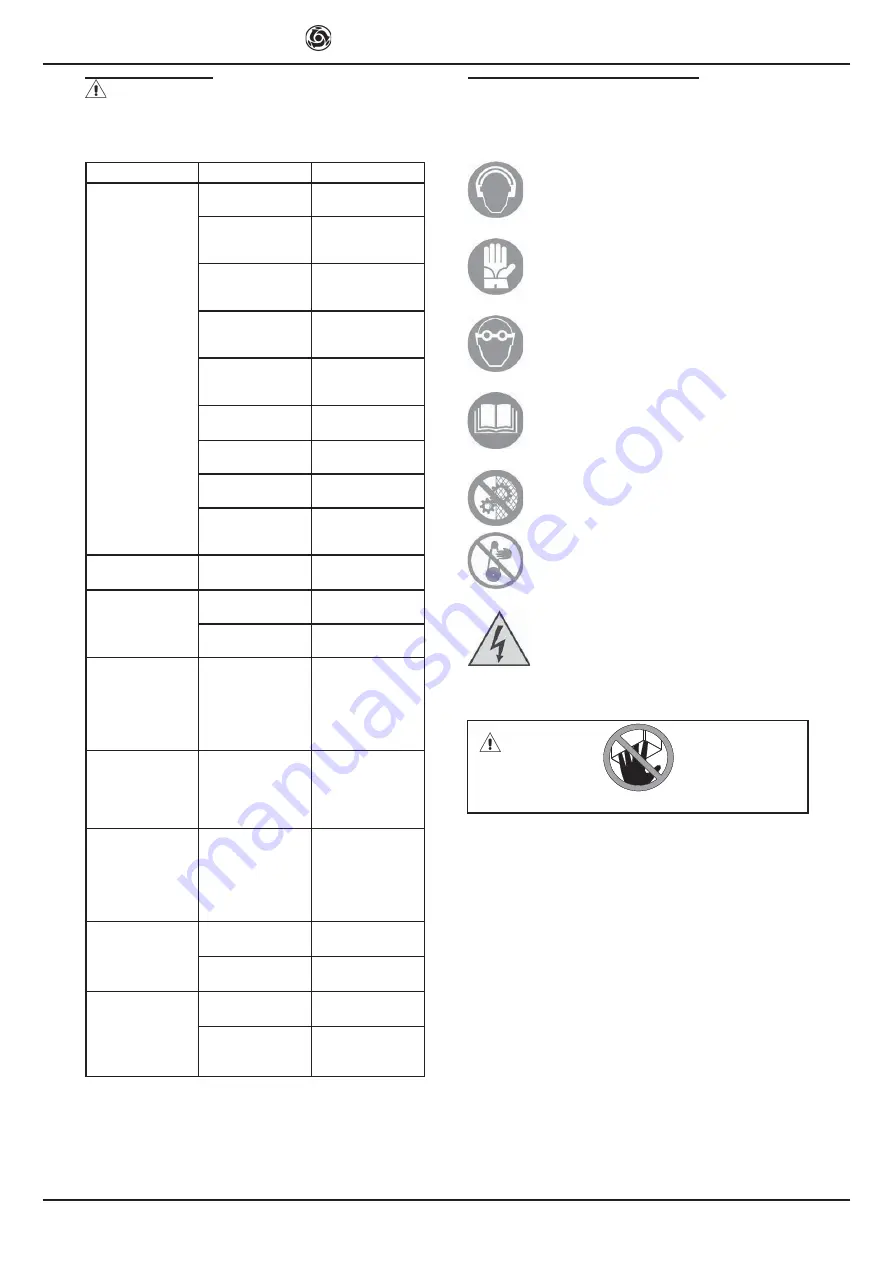

12. TROUBLESHOOTING

. WARNING!

Switch the machine off by pressing the OFF pushbutton and di-

sconnect from power supply before carring out any maintenance

operations.

PROBLEM

CAUSE

REMEDY

(MIXER WITH

ELECTRIC MOTOR)

The motor does not

start when switched

on.

- No power in the

supply line

- Check the line

- The electric plug

and socket are not

connected properly

- Make a proper

connection

- The cable from the

plug to the electric

panel is broken

- Replace the cable

- A wire has become

disconnected inside

the panel

- Re-make the

connection

- A wire has become

disconnected on the

motor terminal board

- Re-make the

connection

- The pushbutton is

faulty.

- Replace the

pushbutton.

- The protective cover

is open

- Close it

- The limit switch is

faulty

- Replace it

- A wire has becone

disconnected inside

the limit switch

- Re-make the

connection

The endothermic

motor does not start

- See motor manual

The discharge outlet

leaks water

- The sealing gasket

is worn

- Replace the rubber

- The spring is broken

or ineffective

- Replace the spring

Scraper rubbers do

not mate with the

tank

- Worn rubbers

- Replace the

rubbers and/or

adjust their

position (11.3

MIXING PADDLE

REPLACEMENT)

The outlet will not

open

- Depositin the outlet

protector

- Remove and clean

the outlet(11.2

REMOVAL OF TANK

PROTECTION

COVER)

During mixing,

the paddle rpm

decreases or

paddles stop

- Belts are slack and

are slipping

- Tension the

belts(11.4

TENSIONING

AND REPLACING

TRANSMISSION

BELTS)

Water does not

arrive at the tank

- There is no water in

the feed line

- Change the feed

line

- Water hose or valve

blocked

- Clean the hose or

valve

The blades do

not stop when the

protection cover is

raised

- Limit switch not

mounted correctly

- Adjust position of

limit switch (11.1)

- Cam not mounted

correctly

- Refer to limit

switch adjustment

instructions (11.1)

GB

13. RESIDUAL RISKS AND SAFETY NOTICES

Although the machine is constructed in line with established legislation,

certain residual risks cannot be eliminated and require the use of indivi

dual safety equipment. The machine is equipped with notices to indicate

the residual risks and how to avoid them.

NOISE HAZARD

Wear ear defenders

HAND CRUSHING/SHEARING HAZARD

Wear gloves

EYE INJURY HAZARD

Wear safety glasses

INCORRECT USE HAZARD

Read the manual before operating the machine

TRAPPING/CRUSHING AND SHEARING HAZARD

Do not remove the guards

Do not touch drive components

ELECTROCUTION HAZARD

Danger - electrical power

Note that the employer is responsible for ensuring his workers use indi-

vidual safety equipment.

CAUTION !!!

Keep the hands away from the outlet.