9

IMER INTERNATIONAL S.p.A.

TR 225 N

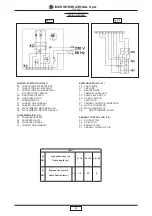

- Insert the plug into a 16A IP67 EEC socket socket and tighten down

the retainer collar.

- The hoist is now ready for testing.

5. TESTING

:DUQLQJ7HVWLQJPXVWEHFDUULHGRXWE\TXDOL¿HG

personnel. Take all necessary safety precautions.

- Warning! The winch must be tested before use.

Before testing the hoist make sure that it has been correctly installed.

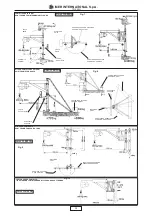

1) Lower the unloaded rope to the lower loading position, and check

that at the end of its travel three turns of rope remain on the drum.

2)

No-load test.

$SSO\DVPDOOORDGNJDQGUXQDFRPSOHWHXS

down cycle.

Test the up, down and emergency stop buttons, UP limit switch

operation, correct rope winding onto the drum and motor brake

operation.

3)

Load test.

Load the hoist with its maximum admissible load. Run

DFRPSOHWHXSGRZQF\FOHWRWHVWWKHVWDELOLW\RIWKHVXSSRUWVDQG

the motor brake.

After the test, check the support structure for failure and slippage and

recheck the drum level (use a level as in Fig. 1).

4)

7KHKRLVWLV¿WWHGZLWKDVDIHW\ZKLFKVWRSVWUDYHODWWKH83

and fully unwound positions DOWN (16) to avoid the rope winding

on in the wrong direction.

Do not depend on this safety to stop the winch; release the control

button to stop the winch instead.

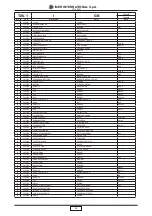

:KHQWHVWLQJLVFRPSOHWHG¿OOLQWKHWHVWUHSRUWZLWKWKHGDWH

installation check and signature (Table 2) along with any other

comments.

The test procedure described above, complete with

no-load (2) and load (3) tests, must be performed every time

the machine is installed.

6. SAFETY WARNINGS AND OPERATING PRECAUTIONS

- 1) Do not lift weights exceeding the hoist’s capacity.

- 2) Do not allow anyone to stand underneath suspended

loads.

- 3) Do not attempt to raise loads that are anchored to

the ground (e.g. buried posts, plinths, etc.).

- 4) Make sure that the load is correctly attached to the

KRRN RQ WKH KRLVW DQG DOZD\V FORVH WKH VDIHW\ FDWFK ¿J

4.1, 6).

- 5) If the load requires the attachment of accessories

EHOWVURSHVVOLQJVHWFWKHVHPXVWEHRIDFHUWL¿HGDQG

approved type. The maximum capacity must be reduced by

the weight of these accessories.

- 6) Make sure that no part of the load detaches while it

is being lifted.

0DNHVXUHWKDWWKDWWKHORDGLVUHVWLQJ¿UPO\RQWKH

ground before releasing it from the hook.

- 8) Do not release a suspended load using accessories

that permit instantaneous release or by cutting the sling

since this can give rise to an elastic counter-reaction of the

entire structure.

- 9) Keep your hands and body well clear of the drum

during operation to avoid them getting caught in the winding

rope; this can result in serious injury.

- 10) Keep your hands and body well clear of the

counterweight during lifting to prevent them being crushed

against the stop lever.

- 11) Do not use the machine in adverse weather

conditions (strong wind or storms) as the load is not guided.

- 12) The control position and lighting conditions must

permit a good view of the load throughout its travel.

- 13) Check that all guards are in place.

- 14) During operation check that the rope winds on

correctly, one turn at a time, without slack or overlaps, as

this can damage it. If it fails to do so, unwind it and rewind it

correctly under tension.

- 15) Make sure that the lifting run is free from obstacles

and make sure that no one can lean out from intermediate

ÀRRUV

- 16) Cordon off the ground loading area to prevent

anyone from entering during lifting.

- 17) Keep children away from the hoist.

- 18) Do not allow unauthorised persons access to the

hoist while it is not being used.

- 19) The hoist must not be used for pulling loads

obliquely (more than 5° away from vertical).

- 20) Do not rotate the winch on its pivots by pulling the

pendant; move the frame itself by hand;

- 21) Do not leave a suspended load unattended. Raise

or lower it and unload it.

- 22) When a load is to be raised or lowered, this must

be done in such a way as to minimise dangerous sideways

and vertical movements.

- 23) Before leaving the hoist unattended, remove the

load, completely wind the rope onto the drum and disconnect

its power plug.

- 24) Do not allow the load to spin while it is being raised

or lowered as this could cause the rope to break.

- 25) Protect the winch against the rain.

When operation is resumed after a lengthy period of disuse the entire

machine must be tested under no-load conditions before starting, as

described above (point 2, Chapter 5).

7. TESTING AND MAINTENANCE

Warning!! Only carry out maintenance with the machine

switched off, unloaded and disconnected from the mains.

5HSDLUVPXVWEHGRQHE\TXDOL¿HGSHUVRQQHORUE\,0(57HFKQLFDO

Service.

- Use only IMER original spare parts.

- Check the motor brake every 6/7 days.

- Ensure that the notices and inscriptions on the

machine are prominently displayed and legible.

- Keep the machine clean of dirt.

- Check the operation of the UP and DOWN position

limit switches at the start of each work shift.

- Check the electrical cable at the start of every work

cycle for accidental damage.

7.1 STEEL ROPE

8VHRQO\QHZURSHVZLWKDPDQXIDFWXUHUVFHUWL¿FDWHRIFRQIRUPLW\

DWWHVWLQJ WKHLU VDWLVIDFWLRQ RI WKH IROORZLQJ VSHFL¿FDWLRQV DQG RI

VWDQGDUG81,(17KHVHDUHPLQLPXPVSHFL¿FDWLRQVURSHV

ZLWKEHWWHUVSHFL¿FDWLRQVPD\EHXVHGZLWKWKHH[FOXVLRQRIWKH2'

which must always be 5 mm.

External diameter :

5 mm

Type :

133 wires anti-spin

Direction of lay :

CDX

Strand dia.:

0.32 mm

6WUDQGVWUHQJWK

1PP

2

Preformed:

Yes

Minimum breaking strain :

16 kN

Length :

31 m

Surface treatment : galvanised and greased

The IMER reference code is given in the spare parts table.

7.1.1 ROPE REPLACEMENT

This operation must be carried out by an authorised IMER

International service centre.

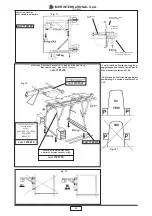

5HPRYHWKHKRRNUHI¿JDQGZLWKGUDZWKHFDEOHZHLJKW

The drum is equipped with a device to ensure that two turns

RIURSHUHPDLQIXOO\ZRXQGRQZKHQDQHZURSHLV¿WWHGWKLV

condition must be maintained.

1) Fully unwind the rope.

2) Withdraw the rope from the inside of the drum through the

hole and the slot.

3) Feed the new rope into the hole and out of the slot on the