E150401X_ENG

27/07/15

7

SECTION

“B” – ALARMS AND TROUBLESHOOTING

It’s possible to see alarms and troubleshooting directly from

. Click the link

below to login to the site and download technical manuals.

SECTION

“C” – USER’S MENU PARAMETERS

1)

ENTERING THE USER’S MENU

It’s possible to complete the programming by changing the parameters of the user’s area.

To access do as follows:

STANDARD IM7 CONTROL CARD with IM7 STANDARD KEYBOARD:

o

Turn on the machine;

o

While the display shows "SELECT A PROGRAM", press the "MENU".

o

On display it will appears "PASSWORD";

o

Type 6 times the button "START/PAUSE";

o

In the

user’s menu the navigation is possible using the arrows to scroll through the

parameters and press "ENTER" to confirm.

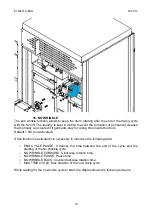

STANDARD IM7 CONTROL CARD with IM7 COIN-OP KEYBOARD:

o

For serial numbers produced BEFORE E201310100, open the door of the lint filter;

o

For serial numbers produced LATER E201310101 do not open the lint filter, opent

the electric bridge marked in the next picture.

o

Close the door;

o

Turn on the machine;

o

Wait for the appearance of the alarm

“DOOR FILTER OPEN”.

o

Push the STOP button within 30 seconds;

o

The display shows

“PASSWORD”;

o

Type 6

times the button “START”;

o

In

the user’s menu the navigation is possible using the arrows to scroll through the

parameters and press "ENTER" to confirm.

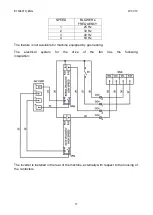

CORRESPONDENCE BETWEEN STANDARD KEYBOARD AND COIN-OP

KEYBOARD

COIN-OP (SELF SERVICE)

STANDARD

HIGH

LEFT

MEDIUM

ENTER

LOW

RIGHT

START/PAUSE

START

STOP

STOP

Summary of Contents for E201003027

Page 8: ...E150401X_ENG 27 07 15 8...