16

TECHNICAL INFORMATION

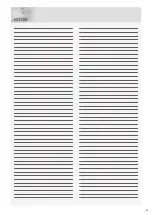

TECHNICAL DATA

Height:

850 mm

Width:

595 mm

Depth:

745 mm

Weight (net):

62 kg

Cylinder volume:

145 l

Max. drying capacity:

8 kg

Speed:

50-55 rpm

Sound pressure level:

The sound pressure level is below 66 dB (A)

Rated power:

See type plate.

Drum material:

Stainless steel

Outer casing material:

Powder-coated and hot-galvanized sheet steel or stainless steel

Setup:

Stacking or freestanding

Test method for noise measurement: IEC 60 704-2-6.

This product contains fluorinated greenhouse gases.

Type of refrigerant:

R134a

Quantity of refrigerant:

0,48 kg

Total GWP:

1430

CO

2

equivalent:

0,686 t

Hermetically sealed.

Summary of Contents for ES80PEHP

Page 23: ...23 NOTES ...