MANCANZA FIAMMA /NO FLAME

(E140901X) 18 di/of 33

ATTENTION: THE ASSISTANCE INTERVENTIONS MUST BE DONE ATTENDING TO

THE PROCEDURES DESCRIBED IN THE MANUALS AND ONLY BY SKILLED

PERSONNEL.

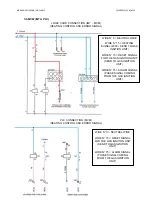

“MISSING FLAME” on IM7 control card unit

There have been three consecutive unsuccessful attempts of gas ignition. The error appears accompanied

by an acoustic warning signal, by pressing the RESET button the starting sequence of the burner will be

retried for other three times. During the presence of the alarm the humid air fan blower and the main roller

continue to operate.

1.

CHECKS THE END USER CAN DO BY ITSELF

Press the RESET button on the keypad and let the machine run the new attempts to ignite the burner.

Verify that there are no closed valves along the gas pipeline which is connected to the machine and verify if

the error “GAS PRESSURE” appeared previously (eventually check the document

).

Locate and write down the name of the program and the cycle during which the alarm occurred. On IM7

control card units the alarm is historicized automatically and can be accessed through the alarm log (

If the alarm does not disappear call the technical service and direct the technician to perform the checks

described in the relevant section.

Communicate to the technical problems of gas supply that occurred in the days prior to the appearance of

the alarm.

2.

INTERVENTION ON SITE BY THE TECHNICIAN

When working on the place you should have with you:

- Equipment to open the back panel of the machine;

- Equipment to disconnect the gas supply pipe of the machine;

- Pressure meter calibrated for reading the gas mBar (millibar);

- Digital Multimeter with voltmeter function.

After performing the checks again the final customer did, make sure that the gas pipeline is really under

pressure and that it is properly sized according to the heating power installed along the line.

Operate the necessary checks on gas and on the air drawn by the machine as described below.

3.

GAS: PRESSURE AND CARRYING CAPACITY

3.a INPUT PRESSURE CHECK (STATIC PRESSURE).

Turn off the machine completely. Close the gas valve that supply the machine. Go on the side, open the side

panel of the machine and locate the gas valve shown in the figure. Open the screw contained in the pressure

tap "P in" using a screwdriver (the screw, although completely loose

, can’t get out of his socket). Connect

your pressure gauge meter to the pressure "P in" and gently open the gas valve.

At this time check the pressure value of the stabilized pipeline. During this reading is not necessary to turn

on the machine.

For valves model SIT 840 SIGMA inlet pressure must always be less than 60 mbar.