2

Please take a few moments to carefully read through this manual. Correct maintenance and

operation of this machine will provide the best possible performance from your product.

iMettos LM Series Spiral Mixers

ATTENTION

New user or repairing this product must be performed by the experts or qualified person or those who

have gotten the license of installation, or those who are authorized by the manufacturer.

When installation or maintenance, please obey the following instructions carefully to ensure the safety

use of this appliance.

Please keep this instruction Manual for future reference, or hand it to next user.

Put off the package to make sure none of the parts is missing or damaged. If there is any doubt about

the product, please do not use it, and consult it to the experts.

Keep the packing material out of reach of the children to avoid accident( Especially the plastic bag,

screw etc)

This appliance could be only operated by the person who is familiar with the unit.

When not using the appliance or the operator is absent, please turn off the unit to avoid any accidental

injury or damage.

When it needs to be repaired, please ask for expert, and use the original fitted spare part. It will be

dangerous if not following the above requirements.

This appliance is just for commercial using, not for any other use, otherwise, it may be dangerous.

Do not rinse the equipment with water directly.

Clean the surface of stainless steel periodically with appropriate method to prevent any damage

brought by oxidization or any other chemical interference.

1.

DESCRIPTION

LM spiral mixer is a new type of kneader. Both the dough arm and bowl are running, that it can raise the

mixing speed and efficiency greatly. The machine is equipped with protect cover, easy operable and safety.

Overall, the machine is food looking, easily operable and very efficient, suitable for food preparation in

hotels, restaurants, food processing factories and for material preparation in medicine making factories,

chemical working facilities etc

2.

FORWARD

We reserves the right to alter the design of their products without prior notice. Whilst every effort is made

to ensure this publication reflects the latest design, the company cannot guarantee full compliance.

Technical specifications

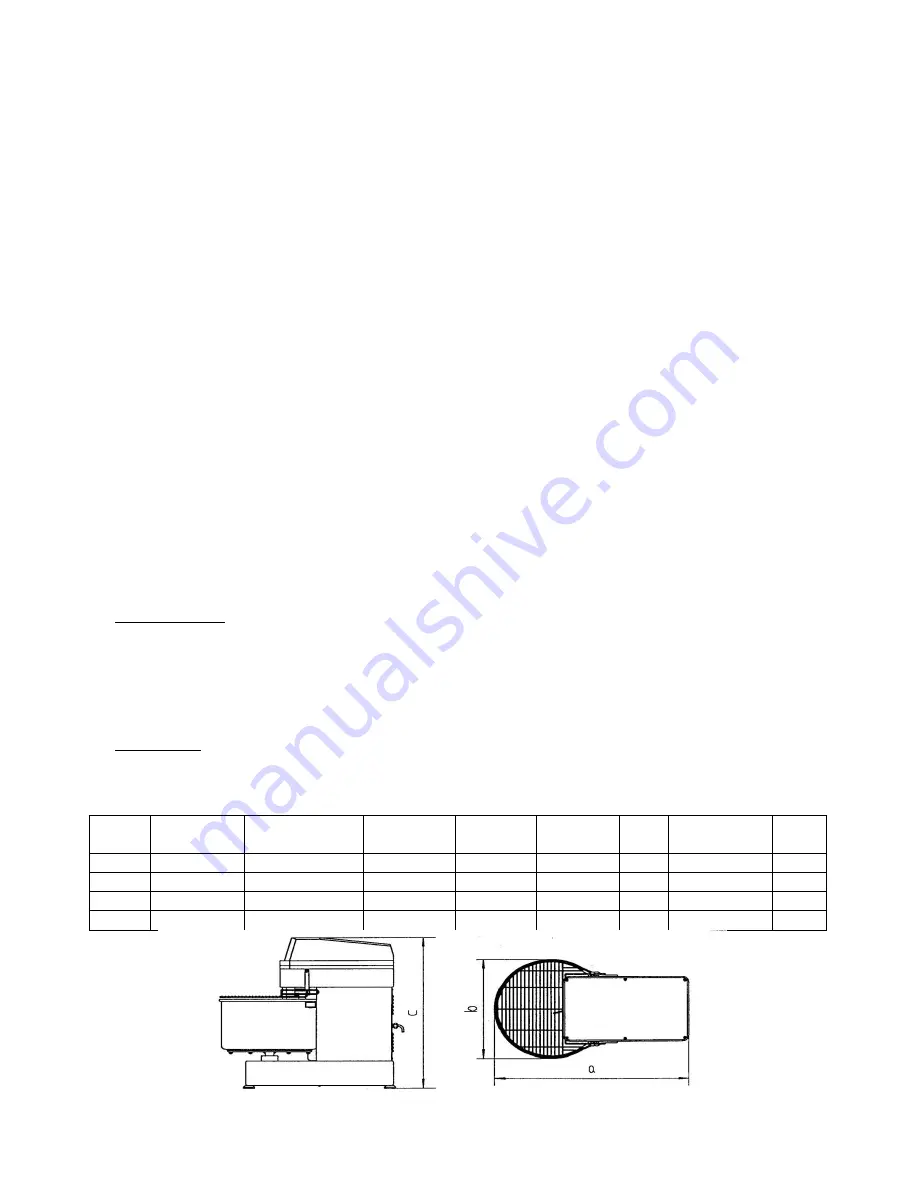

Model

Bowl capacity

(L)

Max flour capacity

(kg)

Mixing speed

(r/min)

Bowl speed

(r/min)

Voltage

(

V/Hz)

Power

(kw)

Dimensions

(mm)

Weight

(kg)

LM20

20

8

202

16

220-240/50

0.75

690x380x730

70

LM30

30

12

202

16

220-240/ 50

1.1

730x430x770

90

LM40

40

16

202

16

220-240/50

2.2

870x480x935

127

LM50

50

20

202

16

220-240/50

2.2

920x530x935

130