F64B, F64L Ultra high efficiency coalescing filter

Installation & Maintenance Instructions

3/19

I&M/en 8.240.115.01

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document. (1999 - I&M8076c) © 2015 IMI International s.r.o.

Technical features

Option selector

Port

2 1/4”

3 3/8“

4 1/2“

6 3/4

N

No yoke

Bowl

P

Transparent with guard

R

Metal with Pyrex sight glass

T Transparent

Thread

A

PTF (1/8 PTF gauge ports)

B

ISO Rc taper (1/8 ISO Rc gauge ports)

G

ISO G parallel (1/8 ISO Rc gauge ports)

N

No thread (basic unit)

F64

˙

–

˙˙N

–

˙˙0

Drain

A Automatic

M Manual

Type

B

Coalescing & activated

carbon element

L

Extended coalescing &

activated carbon element

Fluid: Compressed air

Maximum pressure:

Metal bowl: 17 bar (250 psig)

Transparent bowl: 10 bar (150 psig)

Operating temperature*:

Metal bowl: –20° to +65°C (0° to +150°F)

Transparent bowl: –20° to +50°C (0° to +125°F)

* Air supply must be dry enough to avoid ice

formation at temperatures below +2°C (+35°F).

Integral F64B/L Pre-filter Element: 40 μm

nominal

Particle Removal F64B/L: 0,01 μm

Maximum Remaining Oil Content:

0,003 mg/m

3

at +21°C (+70°F)

Air Quality: Within ISO 8573-1: class 1.7.1

Inlet pressure Maximum Flow dm

3

/s (scfm)*1)

bar (psig) F64B F64L

1 (14,5) 2,8 (5,9) 4,4 (9,3)

3 (43,5) 4,8 (10,2) 7,6 (16,1)

5 (72,5) 6,2 (13,1) 9,8 (20,8)

6,3 (91,4) 7,0 (14,8) 11,0 (23,3)

7 (101,5) 7,3 (15,5) 11,5 (24,4)

9 (130,5) 8,4 (17,8) 13,2 (28,0)

*1) Maximum flow to maintain stated oil removal

performance.

Automatic drain connection: 1/8”

Automatic drain operating conditions

Bowl pressure required to close drain:

Greater than 0,3 bar (5 psig)

Bowl pressure required to open drain:

Less than 0,2 bar (3 psig)

Minimum air flow required to close drain:

1 dm3/s (2 scfm)

Manual operation: Depress pin inside drain

outlet to drain bowl

Nominal bowl size: 0,2 litre (7 fluid oz)

Materials:

Body: Zinc

Bowl:

Metal: Zinc

Transparent: Polycarbonate

Guard, transparent bowl: Steel

Metal bowl sight glass, standard: Pyrex

Element: Composite materials

Elastomers: Synthetic rubber

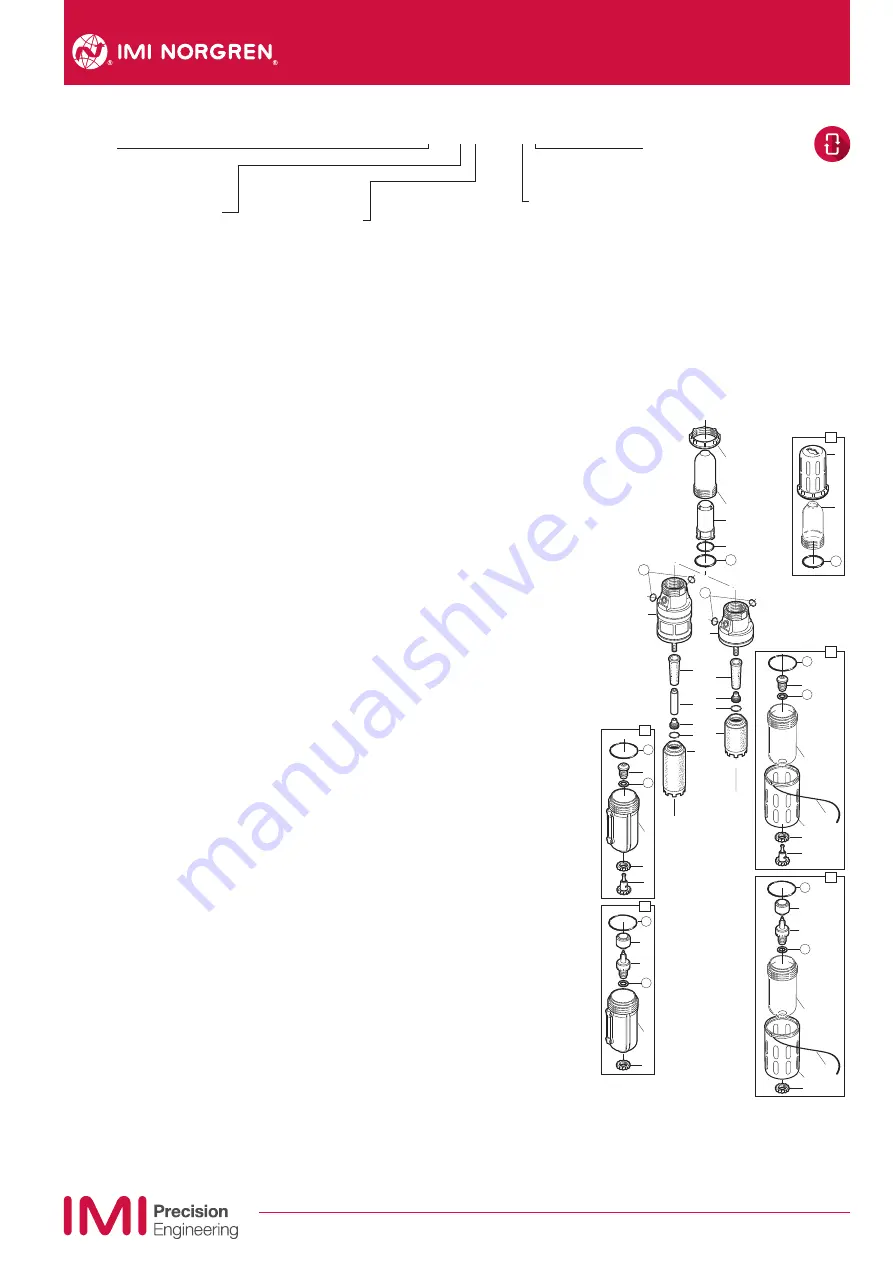

Replacement Items

Service kit,

contains required items circled

4380-201

Pyrex sight glass

2273-97

Element, coalescing:

F64B

5350-99

F64L

5350-98

Element, integral pre-filter

3698-02

Activated carbon pack

5568-01

Manual drain

684-84

Automatic drain

3000-04

Installation

1. Install unit vertically in air line - upstream of

lubricators and cycling valves, with air flow in

direction of arrow on body, as close as

possible to the device being serviced.

2. Before assembling the basic unit into the yoke

the port seal o-rings should be lightly smeared

with o-ring grease.

3. Locate clamp ring under lugs on top of yoke,

offer basic unit into yoke with directional

arrows correctly aligned (an interference fit

prevents assembly if misaligned) before

engaging and fully tightening the clamp ring.

4. Turn bowl fully clockwise into body before

pressurizing.

5. Auto-drain units may be fitted with a short

drain pipe and connector, minimum 5 mm

bore, to the G1⁄8 bottom outlet.

6.Install a Norgren general purpose filter with a

5 μm element upstream of the oil removal filter

to obtain maximum element service life.

Operation

On exceptionally dirty lines it may be necessary

to clean the pre-filter element at 90 day intervals.

Do not exceed Maximum Flow rating or

excessive pressure drop will result or oil carry

over may occur. The top filter element acts as

absorbant pack to remove any small traces of oil

or hydro-carbon gases which might be carried

over from the lower bowl. These elements also

provide protection in the event of any failure of

the lower filter. Resistance to air flow will grad-

ually increase as the filter element collects solid

particles. The pressure differential across the

element should not be allowed to exceed

Servicing

Air Service equipment should be initially

maintained annually. Use, quality of air and

condition at examination may indicate

adjustment of the maintenance interval.

1. Open manual drain to expel accumulated

liquids. Keep liquids below element (46, 50).

2. To operate automatic drain manually, lift

operating pin in bottom outlet with a blunt rod.

3. Clean or replace filter element when dirty.

Disassembly

1. Shut off inlet pressure. Reduce pressure in

inlet and outlet lines to zero.

2. For ease of maintenance the unit can be

removed from the yoke by unscrewing the

clamp ring, which will jack the unit out

downwards.

3. To disassemble the lower filter section

unscrew the filter bowl (14, 21, 28, 37) and

remove with bowl o-ring.

4. Remove coalescing element (46, 50) by hand.

5. Remove pre-filter element (49, 54).

6. Unscrew top bowl and remove top element

(8).

7. Disassemble in general accordance with the

item numbers on exploded view. Do not

remove the drains unless replacement is

necessary. Remove and replace only if they

malfunction.

42

44

43

8

9

1

2

5

6

3

11

49

48

47

46

10

12

15

19

38

39

40

41

16

17

20

18

45

13

54

53

52

51

50

29

30

35

32

33

36

31

34

22

24

26

25

23

27

4

14

21

28

37

7

Cleaning

1. Partial cleaning of the pre-filter element (49,

54) is possible by washing the element in

soapy water and blowing out thoroughly

with compressed air. Replacement by a clean

element is recommended.The main