11

INS

TALLER

US

ER

MAINTEN

AN

CE TECHNI

CI

AN

2.5 IGNITION OF THE BOILER.

Before ignition make sure the central heating

system is filled with water and that the pressure

gauge (12) indicates a pressure of 1 - 1.2 bar;

- Open the gas cock upstream from the boiler.

- Turn the main selector switch (9) to Domestic

Hot Water/Comando Amico Remoto

V2

(CAR

V2

) (

) or Domestic Hot Water

and Central heating(

).

N.B.:

Once the main selector switch has been

placed (9) on one of these positions, the presence

of voltage is indicated by the switch-on with a

fixed light of one of the LEDS from 4 to 8, which

indicate the temperature of the output water from

the main heat exchanger.

Attention:

if any one of the LEDs 4 to 8 starts

flashing, this means that there is a fault. Refer to

the next paragraph.

Functioning of the boiler in domestic water mode

and in heating mode is indicated respectively by

the switch-on of LED 2 or LED 3 with a fixed light

(in absence of remote controls).

• Operation with Remote Control (Optional).

With selector switch (9) in position (

) and Remote Control connected to the boiler

selector switches (10) and (11) excluded. The

boiler adjustment parameters are set from the

control panel of the Remote Friend Control.

Connection to the Remote Control is indicated

by the contemporary fixed switch-on of LEDs

2 and 3 (

). Also in the presence

of Remote Control the indications of the

temperature and any faults are maintained on

the control panel.

•

Operation without Remote Control. With

the selector switch (9) in position (

)

the heating adjustment selector switch (11) is

cut out, the domestic hot water temperature

is regulated by selector switch (10). With

the selector switch in position (

) the

heating adjustment selector switch (11) is used

to regulate the temperature of radiators, while

selector (10) continues to be used for domestic

hot water. Turn the selector switches clockwise

to increase the temperature and anti-clockwise

to decrease it.

From this moment the boiler functions

automatically. With no demand for heat (heating

or domestic hot water production) the boiler

goes to “standby” function, equivalent to the

boiler being powered without presence of

flame (LED corresponding to the ignited boiler

temperature). Each time the boiler lights up, the

relative flame present symbol is displayed by the

green LED 1 ( ).

N.B.:

The boiler may start-up automatically if the

anti-freeze function is activated.

2.6 TROUBLESHOOTING.

The Nike Mini 28 kW Special boiler signals an

anomaly by flashing of one of the LEDs from 4

to 8 or LEDs 1 and 2 coupled to LED 7. The error

code will be displayed on any remote control by

a numerical code preceded or followed by the

letter E (e.g. CAR

V2

= Exx).

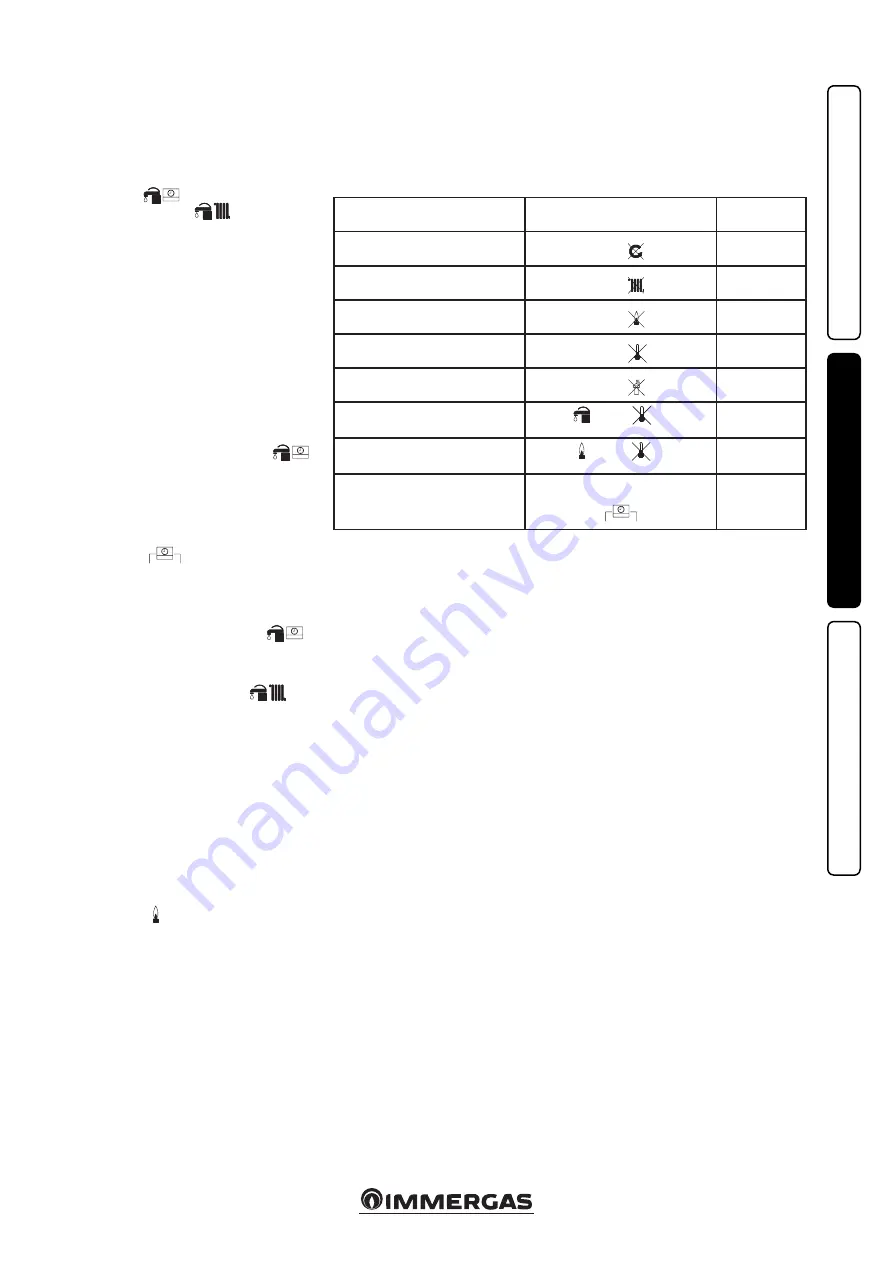

Anomaly signalled

LED

flashing

Remote display

Insufficient circulation

LED 4 (

)

27

Flow probe anomaly

LED 5 (

)

05

No ignition block

LED 6 (

)

01

Safety thermostat block (over-

temperature)

LED 7 (

)

02

Flue safety thermostat block

LED 8 (

)

03

Contacts resistance block

LEDs 2 (

) and 7 (

) flash at the

same time

04

Parasite flame block

LEDs 1 (

) and 7 (

) flash at the

same time

20

Loss of remote control

communication

LEDs 2 and 3 flash alternately

(

)

31

Insufficient water circulation.

This occurs

if there is overheating in the boiler due to

insufficient water circulating in the primary

circuit; the causes can be:

- low system circulation; check that no shut-off

devices are closed on the heating circuit and

that the system is free of air (deaerated);

- pump blocked; free the pump.

If this phenomenon occurs frequently, contact

a qualified technician for assistance (e.g. After-

Sales Technical Assistance Service).

Delivery probe anomaly.

If the board detects an

anomaly on the system NTC flow probe (code

05) the boiler will not start; contact a qualified

technician for assistance (e.g. After-Sales

Technical Assistance Service).

Ignition block.

The boiler lights up with

each demand for room heating or hot water

production. If the burner does not ignite within

10 seconds, the boiler remains in stand-by

for 30 seconds, tries again and if the second

attempt fails it goes into “ignition block” (LED

6 flashing). To eliminate “ignition block” the

main selector (9) must be temporarily turned

to the Reset position. The anomaly can be reset

5 consecutive times, after which the function is

inhibited for at least one hour. It is possible to try

once every hour, for a maximum of 5 attempts.

By switching the appliance on and off the 5

attempts are re-acquired. On commissioning

or after extended appliance downtime, it may

be necessary to eliminate the “ignition block”.

If this phenomenon occurs frequently, contact

a qualified technician for assistance (e.g. After-

Sales Technical Assistance Service).

Safety thermostat block (overheating).

During

operation, if a fault causes excessive overheating

internally, in the exhaust, or an anomaly occurs

in the flame control section, an overheating

block is triggered in the boiler (LED 7 flashing).

To eliminate the “overheating block” the main

selector (9) must be temporarily turned to the

Reset position. If this phenomenon occurs

frequently, contact a qualified technician for

assistance (e.g. After-Sales Technical Assistance

Service).

Flue safety thermostat block.

This occurs if

the fumes evacuation pipe does not function

correctly. The boiler goes into stand-by for

30 minutes, after which, if normal working

conditions are restored, it re-starts without

having to be reset. In the case of 3 consecutive

blocks, the boiler itself blocks and it must be reset

in order to re-start. It is nevertheless necessary

to call a qualified technician (e.g. After-Sales

Technical Assistance Service) in order to solve

the problem.

Contacts resistance block.

This occurs in the

case of faults to the safety thermostat over-

temperature). The boiler does not start and

a technician must be called (e.g. After-Sales

Service).

Parasite flame block.

This occurs in case of a

leak on the detection circuit or anomaly in the

flame control unit. The boiler does not start and

a technician must be called (e.g. After-Sales

Service).

Summary of Contents for 3.018921

Page 1: ...NIKE MINI 28 KW SPECIAL Instruction and warning booklet 1 040845ENG...

Page 21: ......

Page 22: ......

Page 23: ......