34

2-19

1

2

3

INS

TALLER

US

ER

MAINTEN

AN

CE TECHNI

CI

AN

2.10 BOILER SHUTDOWN.

Switch the boiler off by pressing the “ ” but-

ton on the remote zone control, disconnect the

onmipolar switch outside the boiler and close

the gas cock upstream of the appliance. Never

leave the boiler switched on if left unused for

prolonged periods.

2.11 RESTORING CENTRAL HEATING

SYSTEM PRESSURE.

Periodically check the system water pressure.

The boiler pressure gauge should read a pressure

between 1 and 1.2 bar.

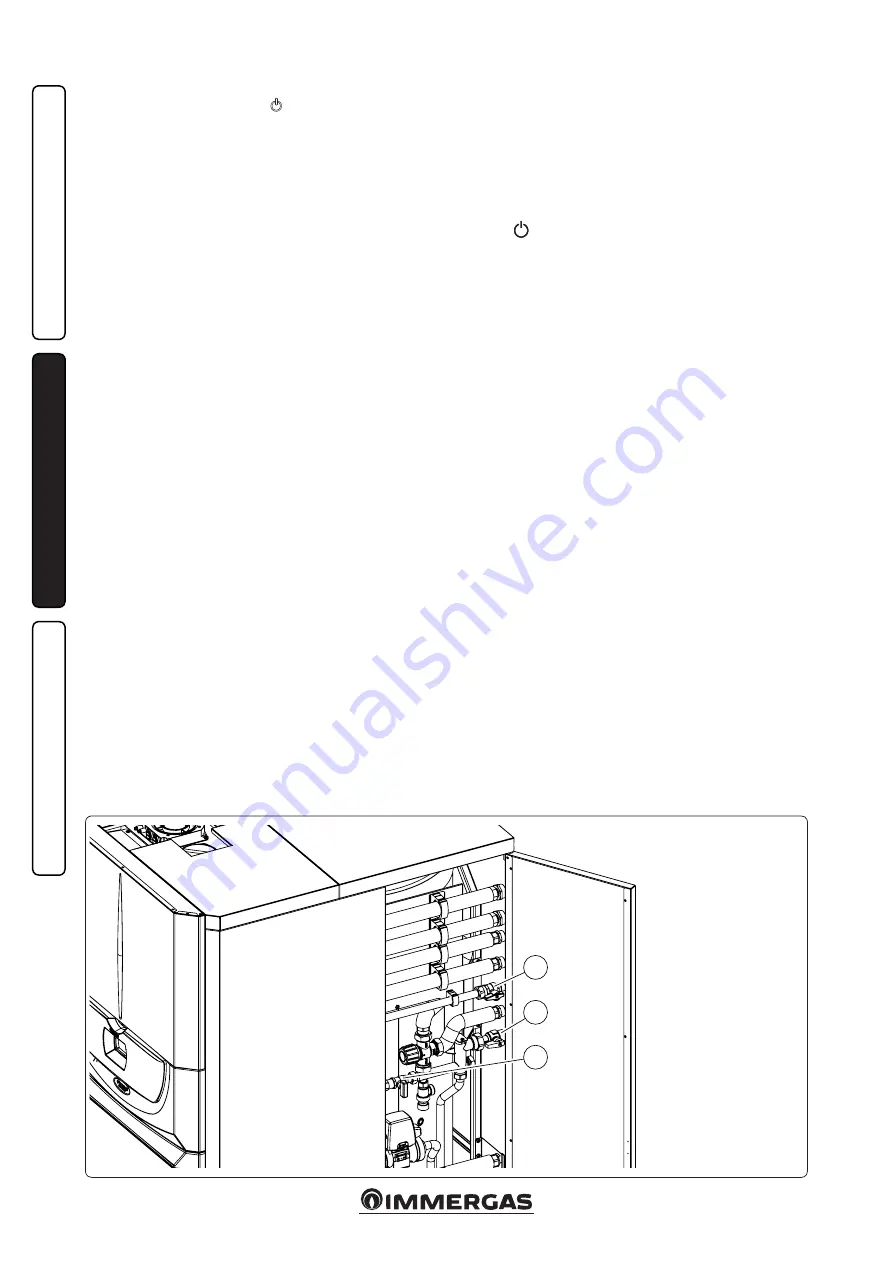

If the pressure falls below 1 bar (when the circuit is

cold) restore normal pressure via the relevant valve

located to the right of the boiler and accessible from

the side door (Fig. 2-19).

N.B.:

close the cock after the operation.

If pressure values reach around 3 bar the safety

valve may be activated.

In this case, remove water from an air vent valve

of a radiator until 1 bar is reached or ask for as-

sistance from an authorised company.

If frequent pressure drops should occur, ask an

authorised company for assistance to eliminate

the possible system leakage.

2.12 EMPTYING THE SYSTEM AND THE

STORAGE TANK.

In order to empty the boiler, act on the relative

draining valves and remove the air vent valve

on the storage tank to let air into the storage

tank. 1-30).

Before draining, ensure that the filling valve is

closed.

2.13 ANTI-FREEZE PROTECTION.

The boiler comes standard with an anti-freeze

function that activates the pump and burner

when the system water temperature in the boiler

falls below 4°C.

The antifreeze function is only guaranteed if:

- the boiler is correctly connected to gas and elec-

tricity power supply circuits;

- the boiler is powered constantly;

- the boiler is on and not in stand-by (

)

- the boiler is not in no ignition block (Par.

- the boiler essential components are not faulty.

In the case of prolonged inactivity (second

home), we also recommend to:

- disconnect the electric power supply;

- fully drain the central heating circuit, the boiler

domestic hot water circuit and the condensa-

tion trap. In systems that are drained frequently,

filling must be carried out with suitably treated

water to eliminate hardness that can cause lime-

scale.

2.14 CASE CLEANING.

Use damp cloths and neutral detergent to clean

the boiler casing. Never use abrasive or powder

detergents.

2.15 DECOMMISSIONING.

In the event of permanent shutdown of the boiler,

a qualified company must execute the relative

procedures and ensure that the electrical, water

and fuel supply lines are disconnected and that

the solar manifold is covered.

Key:

1 - Gas cock

2 - Cold water inlet

cock

3 - System filling valve

Summary of Contents for 3.025499

Page 1: ...MAGIS HERCULES ERP IE Instruction and recommendation booklet 1 038684ENG ...

Page 2: ......

Page 39: ...39 3 3 2 2 INSTALLER USER MAINTENANCE TECHNICIAN ...

Page 66: ...66 ...

Page 67: ...67 ...