19

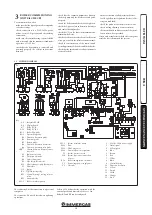

1-25

INS

TALLER

US

ER

MAINTEN

AN

CE TECHNI

CI

AN

1.23 CIRCULATION PUMP.

The boilers are supplied with 2 circulator pumps,

both equipped with speed regulator.

These settings are suitable for most systems.

•

Boiler circulator pump.

The boilers are sup-

plied with a variable speed circulator pump.

When the boiler operates in heating mode, the

pump speed is defined according to the “P57”

parameter setting in the M5 menu (Par. 3.9), in

domestic hot water mode the circulator pump

always runs at maximum speed.

During the heating stage the Auto and Fixed

operating modes are available.

NOTE.:

the ∆T can be controlled compatibly

with the characteristics of the central heating

system and of the boiler.

•

Auto:

automatic pump speed. In this mode one

can choose between the “Proportional head”

and “Constant ∆T” option.

-

Proportional head (

∆

T = 0):

the circulator

speed varies according to the power emit-

ted by the burner, the greater the power the

greater the speed. Within the parameter one

can also adjust the pump operating range,

by setting the maximum speed (adjustable

from 100 %

÷

30 %) and the minimum speed

(adjustable from 30% to the max. set speed).

-

∆T Constant (∆T = 5 ÷ 25 K):

the pump

speed varies to maintain the ∆T constant

between the system flow and return accord-

ing to set value K. Within the parameter one

can also adjust the pump operating range,

by setting the maximum speed (adjustable

from 100 %

÷

30 %) and the minimum speed

(adjustable from 30% to the max. set speed).

•

Fixed (100 % ÷ 30 %):

in this mode, the pump

operates at constant speed, the operating range

is defined between minimum (30 %) and maxi-

mum (100 %).

Pump release.

If, after a prolonged period of

inactivity, the circulation pump is blocked,

unscrew the front cap and turn the motor shaft

using a screwdriver. Take great care during this

operation to avoid damage to the motor.

•

System circulator pump.

The system circulator

pump controls the room heating or cooling re-

quests downstream of the hydraulic manifold.

In fact, the pump is equipped with electronic

control that allows to set advanced functions..

For proper operation one must select the most

suitable type of operation for the system and

select a speed between 2 and 7.

- Constant head program (ΔP C) (4 fig.

1-25).

The circulator pump maintains the

pressure level (head) constant as the system

heat demand decreases (flow rate reduction).

With these settings, the circulator pump is

suitable for all floor systems where all the

circuits must be balanced for the same drop

in head. One can select the power level from a

minimum one to a maximum one by turning

the selector switch clockwise in the relative

power scale.

- Proportional head program (ΔP V) (3 fig.

1-25).

This allows the pressure level (head)

to be proportionally reduced as the system

heat demand decreases (flow rate reduc-

tion). Thanks to this function, the electric

power consumption of the circulator pump

is reduced further: the energy (power) used

by the pump decreases according to the pres-

sure level and flow rate. With this setting, the

pump guarantees optimal performance in

most heating systems, proving particularly

suitable in single-pipe and two-pipe installa-

tions. Any noise of the water flow in the pipes,

valves and radiators is eliminated by reducing

the head. Optimal conditions for thermal

comfort and acoustic well-being. One can se-

lect the power level from a minimum one to a

maximum one by turning the selector switch

counterclockwise on the relative power scale.

Adjustments.

Turn the selector and set it on

the desired curve to adjust the circulator pump.

Automatic vent function (1 fig. 1-25).

The

circulator pump is equipped with a function

that activates its operation for 10 minutes,

alternating the speed between minimum and

maximum, so that the air contained in the cir-

culator pump is expelled by the air vent valve.

Diagnostics in real time:

a light ring (2 fig.

1-25) supplies, with different colours, informa-

tion relating to the circulator pump operating

status, see table below.

Key:

1 - Automatic vent mode

operation

2 - Light ring to indicate the

operating status

3 - Proportional head opera-

tion

4 - Constant head operation

5 - Operating mode selector

switch

LED

Description

Diagnostics

Cause

Remedy

Green (on)

Normal functioning

Green

(fast flashing)

Automatic vent in operation The circulator pump vents for

10 minutes

Air in circulator pump

If the circulator pump requires

the automatic vent function

often, one must adjust the op-

erating mode properly.

Red (on)

Green (flashing)

Abnormal situation

Circulator pump working but

stationary

The circulator pump restarts

once the abnormal situation

has been solved

a) voltage out of range

(160 ÷ 253V)

b) circulator pump tempera-

ture high

a) check power supply

b) check temperature of room

and of the water contained

in the system

Red (flashing)

Circulator pump blocked

the circulator pump cannot

restart automatically due to an

anomaly

check the circulator pump

if the problem persists replace

the circulator pump

LED (off)

circulator pump not working electronics not powered

a) circulator pump not con-

nected

b) LED damaged

c) electronics damaged

a) check the electrical connec-

tions

b) check that the circulator

pump is working

c) replace the circulator pump