20

1-16

INS

TALLER

US

ER

MAINTEN

AN

CE TECHNI

CI

AN

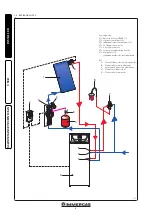

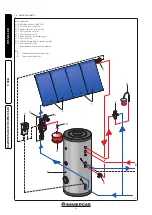

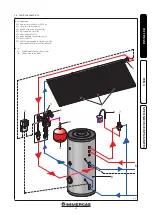

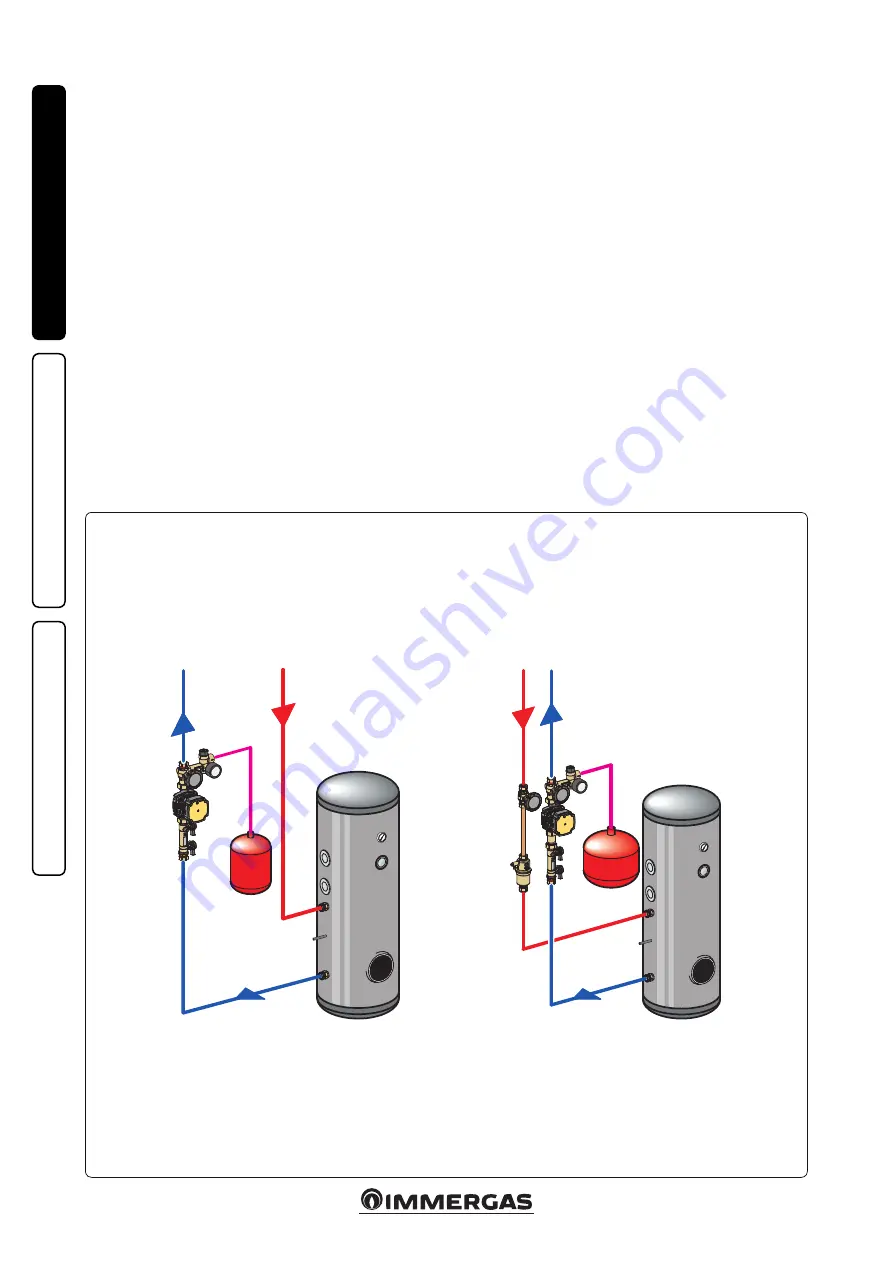

1.15 CIRCULATION UNIT HYDRAULIC

CONNECTION.

The device is pre-assembled before delivery. The

pipes for connection must be ordered separately.

To avoid any vapour entering the expansion

vessel, position the expansion vessel lower than

the collectors. If the vessel is positioned above

the collectors height, it must be connected by

means of a particular pipe to prevent the vessel

from heating up (this pipe, which is not supplied

by Immergas, interrupts the laminar circulation).

Every time the system is emptied, it must be

rinsed well with running water. The circulation

unit is not designed for use in direct contact with

swimming pool water.

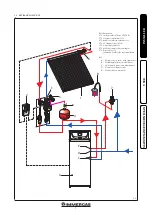

1.16 ASSEMBLY INSTRUCTIONS.

a) remove the device from the insulation casing

by removing the front and rear halves.

b) drill two holes Ø 8 on the wall in correspond-

ence with the holes on the supporting plate.

c) fix the supporting plate to the wall by placing

the rear half of the insulation casing.

d) connect the circulation group fittings in

accordance to the indications of the figures

using the fittings kit supplied separately. If

using copper pipes or pipes of limited physical

resistance their terminals must be reinforced.

The terminal part of the pipe must be cut

perpendicular in respect to the pipe axis and

cleaned.

e) Mount the safety valve unit on the circulation

unit. The safety valve outlet must be connected

to a draining funnel. Otherwise, the manu-

facturer declines any responsibility in case of

flooding if the drain valve cuts in.

f) Connect the electric cable of the circulation

unit as indicated in the respective manual of

the control unit, positioning it at the centre of

the device.

g)Cover the circulation unit with the front case

previously removed.