21

INS

TALLER

US

ER

MAINTEN

AN

CE TECHNI

CI

AN

1.17 COMMISSIONING.

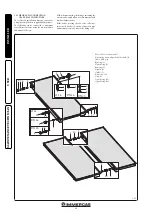

PRELIMINARY CHECKS.

Before filling the hydraulic circuit and starting

the system, carry out the following checks:

- ensure that the declaration of conformity of

installation is supplied with the appliance;

- check the presence of the safety devices and

their functionality, particularly:

- safety valve (6 bar)

- expansion vessel

- thermostatic mixing valve

- check that there are no leaks in the hydraulic

circuit;

- check that there is an air vent valve positioned

in the highest point of the circuit above the

collector and that it is operational.

- check connection of the unit to a network of

230V-50Hz, correct L-N polarity and the earth-

ing connection;

If any checks/inspection give negative results, do

not start the system.

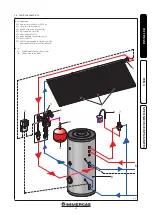

1.18 EXPANSION VESSEL PRE-CHARGE.

To compensate the high temperatures that

can be reached by the liquid in the circuit and

therefore its dilation, an expansion vessel has

been envisioned that has sufficient capacity to

perform this task.

- Kit 1 or 2 flat collectors CP4XL: 18 litre expan-

sion vessel

- Kit 4 flat collectors CP4XL: 35 litre expansion

vessel

- Kit 1 or 2 vacuum collectors CSV14: 35 litre

expansion vessel

- Kit 3 vacuum collector CSV14: 80 litre expan-

sion vessel.

The expansion vessels are supplied factory-set at

1 bar. It is therefore necessary to charge them to

the pressure necessary for the circuit.

The expansion vessel must be charged to:

2 bar + 0.1 bar for every metre of the water

column.

“metre of the water column” means the vertical

distance that is present between the expansion

vessel and the solar collector.

Example:

The circulation unit is found on the ground floor

and the solar collector is found on the roof at a

hypothetical height of 6 m, the distance to be

calculated is:

6 m x 0.1 bar = 0.6 bar

therefore the expansion vessel must be charged

to:

2 + 0.6 =

2.6 bar

1.19 SAFETY VALVE.

There is a safety valve present on the circulation

unit that protects the system from an excessive

increase in pressure. This valve intervenes by

discharging the liquid contained in the circuit

when the pressure reaches 6 bar.

If the safety valve intervenes and therefore part

of the liquid contained in the circuit is lost, this

must be re-integrated.

N.B.:

it is advised to fit the drain valve to a

container / can in order to recover the liquid

contained in the solar circuit.

1.20 FILLING SYSTEM.

The system can only be filled when:

- the system is completely assembled;

- any working residues have been eliminated that

cause obstructions and through time deterio-

rate the features of the glycol;

- all presence of water in the system has been

eliminated, which could cause damage to the

system in winter;

- the absence of leaks has been verified by checks

using air;

- the storage tank unit has been filled;

- the expansion vessel has been charged accord-

ing to system requirements.

The system must be filled only using the glycol

supplied by Immergas via an automatic pump.

The system must be filled with vent valve closed.

N.B.:

do not dilute the “ready to use” propylene

glycol supplied in the solar systems range with

water.

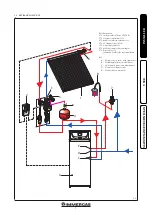

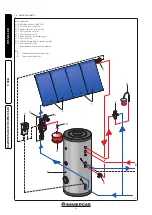

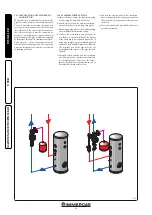

Proceed as follows to fill the system:

1 connect the automatic pump flow pipe to the

filling connector pipe (9 Fig. 1-14) positioned

above the pump and open the filling valve.

2 connect the automatic pump return pipe to the

input regulator pump (8 Fig. 1-14) and open

the drain valve.

3 The flow rate regulator screw (11 Fig. 1-14)

must be horizontal in order to guarantee

closure of the integrated ball valve. Leave the

thermometer in the (ON) reading position.

4 fill the pump tank with the amount of glycol

necessary plus a minimum stock to be left on

the bottom of the tank in order to prevent air

circulating inside the circuit.

5 The filling phase must have minimum duration

of 20 ÷ 25 minutes. This is the time needed

to completely remove all air from the circuit.

Every now and again open the flow rate regula-

tor aeration screw (vertical position).

6 Eliminate any air in the solar circuit preferably

using the so-called “pressure shot” method,

which consists in raising the filling pressure of

the circuit followed by a quick opening of the

return valve (8 Fig. 1-14). This method allows

to expel the air from the circuit.

7 Close the filling valve and switch the filling

pump off, open the regulator screw of the flow

rate regulator (notch in vertical position).

8 Leave the circuit pressurised. Any pressure

drop indicates a leak in the system.

9 Set the functioning pressure in the circuit at

2 bar + 0.1 bar for every metre in the distance

between the solar collector and the expan-

sion vessel (practically, set the same pressure

between expansion vessel and system).

10 Switch the solar pump on at a maximum speed

and make it function for at least 15 minutes.

11 Disconnect the filling pump and close the

fittings using the relevant screwing plugs.