Dear Customer,

Our compliments for having chosen a V2-quality Immergas product, able to assure well-being and safety for a long period of time. As an Immergas customer

you can also count on a qualified after-sales service, prepared and updated to guarantee constant efficiency of its products.

Read the following pages carefully: you will be able to draw useful suggestions regarding the correct use of the device, the respect of which, will confirm your

satisfaction for the Immergas product.

For any interventions or routine maintenance contact Authorised Centres: these have original spare parts and boast of specific preparation directly from the

manufacturer.

General recommendations

All Immergas products are protected with suitable transport packaging.

The material must be stored in dry environments protected against bad weather.

The instruction book is an integral and essential part of the product and must be consigned to the new user also in the case of transfer or succession of ownership.

It must be stored with care and consulted carefully, as all of the warnings provide important safety indications for installation, use and maintenance stages.

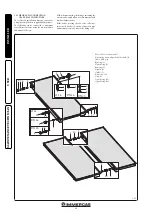

This instructions manual provides technical information regarding installation of Immergas heating solar panels packs. As for the other issues related to in-

stallation of the said products (e.g. safety in the work site, environment protection, injury prevention), it is necessary to comply with the provisions specified

in the regulations in force and principles of good practice.

In compliance with legislation in force, the systems must be designed by qualified professionals, within the dimensional limits established by the Law. Installation

and maintenance must be performed in compliance with the regulations in force, according to the manufacturer’s instructions and by an authorised company,

which has specific technical expertise in the system sector, as required by Law.

Improper installation or assembly of the Immergas appliance and/or components, accessories, kit and devices can cause unexpected problems to people, animals

and objects. Read the instructions provided with the product carefully to ensure a proper installation.

Maintenance must be carried out by an authorised company. The Authorised After-sales Service represents a guarantee of qualification and professionalism.

The appliance must only be destined for the use for which it has been expressly declared. Any other use will be considered improper and therefore potentially

dangerous.

If errors occur during installation, operation and maintenance, due to non compliance with technical laws in force, standards or instructions contained in this

book (or however supplied by the manufacturer), the manufacturer is excluded from any contractual and extra-contractual liability for any damages and the

appliance warranty is invalidated.

The company

IMMERGAS S.p.A.

, with registered office in via Cisa Ligure 95 42041 Brescello (RE), declares that the design, manufacturing and after-sales

assistance processes comply with the requirements of standard

UNI EN ISO 9001:2008.

For further details on the product CE marking, request a copy of the Declaration of Conformity from the manufacturer, specifying the appliance model

and the language of the country.

The manufacturer declines all liability due to printing or transcription errors, reserving the right to make any modifications to its technical and commercial

documents without forewarning.