5

INS

TALLER

US

ER

MAINTEN

AN

CE TECHNI

CI

AN

1

DEVICE

INSTALLATION

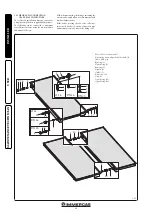

1.1 DESCRIPTION OF THE DEVICE.

The Immergas solar solutions systems are sup-

plied complete for its commissioning with exclu-

sion of fixing systems (e.g. plugs etc.).

The solar collectors are certified and are in com-

pliance with the standards Solarkeymark. They

can be mounted on all roof types or directly on

the ground by means of an additional appropri-

ate structure.

The purpose of this manual is to give general

indications on its installation and relative use of

the complete system.

Installation must be carried out in compliance

with current regulations and by qualified staff.

Installation must be carried out according to the

standards, current legislation and in compliance

with local technical regulations and the enabled

companies.

In the event the pack is installed in damp places,

one must provide an insulation system under-

neath it, to insulate it from the ground.

The place of installation of the appliance and

relative Immergas accessories must have suitable

features (technical and structural) such to allow

(always in safety, efficiency and comfortable

conditions):

- installation (according to the provisions of the

technical legislation and technical regulations);

- maintenance operations (including scheduled,

periodic, routine and special ones);

- removal (to outdoors in the place for loading

and transporting the appliances and com-

ponents) as well as the eventual replacement

of those with appliances and/or equivalent

components.

Before installing the system, ensure that it is

delivered in perfect condition; if in doubt, con-

tact the supplier immediately. Packing materials

(staples, nails, plastic bags, polystyrene foam,

etc.) constitute a hazard and must be kept out of

the reach of children.

In case of failure to use the solar system or pro-

longed absences, cover the collectors to prevent

overheating of the system.

In the event of malfunctions, faults or incorrect

operation, turn the system off immediately and

cover it; it is also necessary to contact an author-

ised company (e.g. the Authorised Technical

Assistance Centre, which has specifically trained

staff and original spare parts). Do not attempt to

modify or repair the appliance alone.Failure to

comply with the above implies personal respon-

sibility and invalidates the warranty.

“Anti-legionella” heat treatment of the Immergas

storage tank (activated by the specific function

present on the predisposed thermoregulatory

systems): during this stage, the temperature of

the water inside the storage tank exceeds 60°C

with a relative risk of burns. Keep this domestic

water treatment under control (and inform

the users) to prevent unforeseeable damage

to people, animals, things. If required install a

thermostatic valve on the domestic hot water

outlet to prevent scalding.

• Installation regulations:

- The control of the entire framework by a statics

expert, according to the Standards in force, is

mostly necessary in areas with large snowfall or

in areas exposed to strong winds. Therefore, all

characteristics of the place of assembly must be

taken into consideration (gusts of wind, vortex

build-up, etc...) which can lead to an increase

of loads on the structures.

- before starting the system, the solar collector

must be covered to protect the absorber from

over-heating and the operator from eventual

burns. The system must only be filled when

all hydraulic connections have been coupled

correctly. It cannot be started until it is possible

to eliminate the heat generated by the solar

collector.

- The collector can be positioned on the basis of

the conditions of the roof (flat or sloping) or in

a prepared free structure. The collector cannot

be positioned with the glass part facing down.

This causes malfunctioning and damage.

- Pay attention not to force or put excessive

traction on the collector connection fittings in

order to prevent damage tot he same and the

internal parts of the collector.

- During movement, use protective gloves and

do not transport the collector holding it by the

connection fittings.

Attention:

- it is in fact obligatory to use antifreeze supplied

by the manufacturer;

- when realising the hydraulic circuit (pipes,

fittings, etc.), only use suitable materials that

resist high temperatures and are suitable for

use with solar systems.

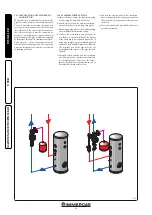

- the use of a boiler involves the installation of a

safety valve, an expansion vessel and a one-way

valve for the appropriately sized domestic hot

water circuit,

these components are not always

included in the package.

N.B.:

if errors occur during installation, running

and maintenance, due to the non compliance of

technical laws in force, standards or instructions

contained in this book (or however supplied by

the manufacturer), the manufacturer is excluded

from any contractual and extra-contractual

liability for any damages and the warranty is

invalidated.