20

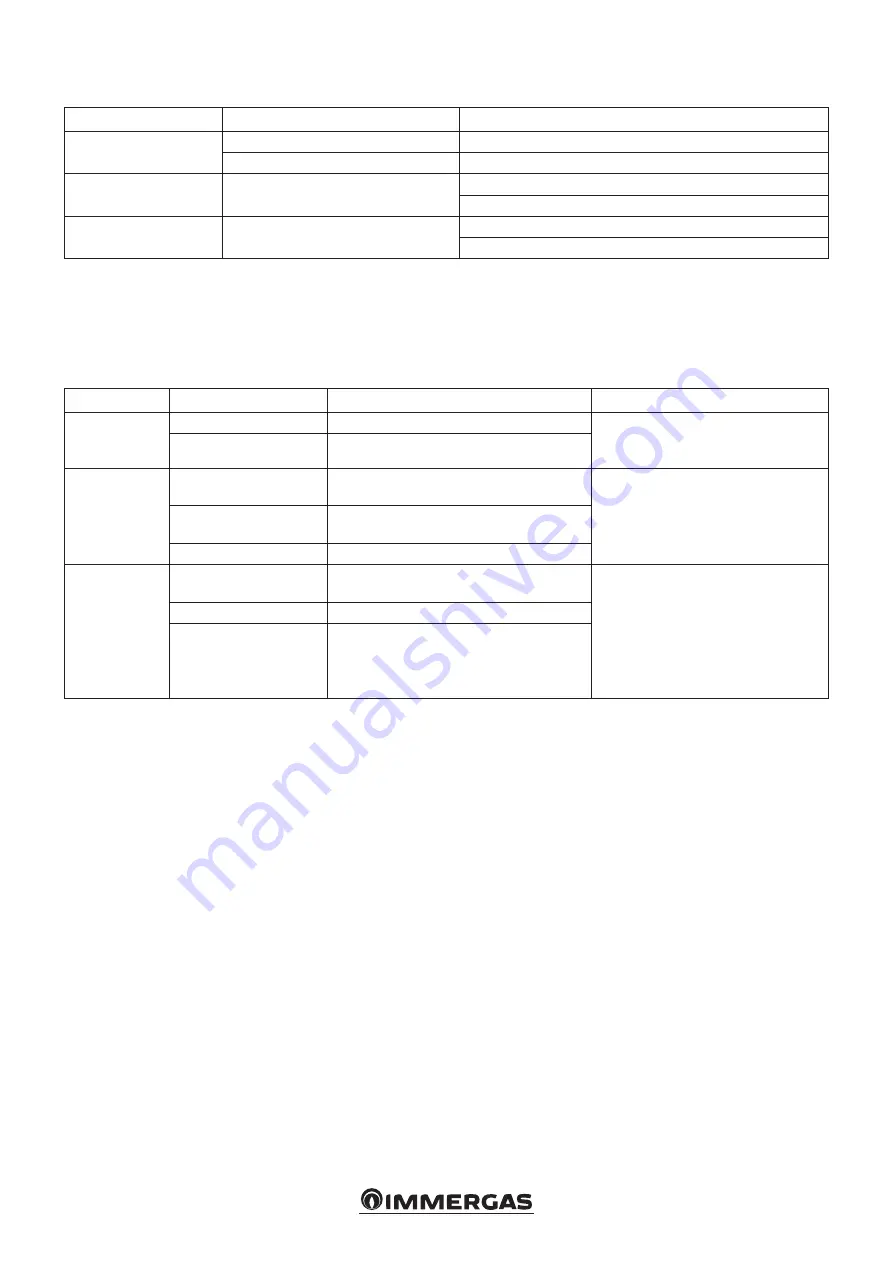

Troubleshooting.

Faults

Causes

Solutions

Pump not working with

power supply on.

Faulty electrical fuse

Check the fuses

The pump is without voltage

Eliminate the power supply cut-off

The pump generates

noise

Cavitation due to insufficient flow pres-

sure

Increase the system pressure within the allowed field

Check the head setting and eventually set a lower head

The building does not

heat up.

Heat output of the radiant panels too

low

Increase the delivery value

Set the adjustment mode to ΔP-c instead of ΔP-v

Diagnostics in real time

- The anomaly LED indicates a fault.

- The pump stops (depending on the fault), and performs

cyclical attempts to restart.

LED

Faults

Causes

Solutions

It lights up red

Block

Rotor seized

Activate the manual restart or contact

the Authorised Technical Service

Centre

Contact/winding

Faulty winding

It flashes with

red light

Under/Overvoltage

Feed side power supply voltage too low/

high

Check the mains voltage and operating

conditions, ask the Authorised

Technical Assistance Centre

Excessive module tem-

perature

Inside of the too hot module

Short-circuit

Motor current too high

It flashes with

red/green light

Turbine operation

The hydraulic system of the pumps is fed

but the pump has no mains voltage

Check the mains voltage, the water

pressure/flow rate as well as the

environmental conditions

Dry operation

Air in the pump

Overload

The motor runs with difficulty. The pump

complies with the specifications (e.g. high

module temperature). The number of

revolutions is lower than normal operation

Manual restart

When a blockage is detected, the pump tries to automatically

restart.

If the pump does not automatically restart:

- Activate the manual restart by pressing the control key for 5

seconds, then release.

- The restart function starts and last max. 10 minutes.

- The LEDs flash one after the other clockwise.

- To interrupt, press the control key for 5 seconds.