12

1-10

1-11

1-12

INS

TALLER

US

ER

MAINTEN

AN

CE TECHNI

CI

AN

1.10 OUTDOOR INSTALLATION IN A

PARTIALLY PROTECTED AREA.

N.B.:

a partially protected location is one in which

the appliance is not exposed to the direct action of

the weather (rain, snow, hail, etc..).

This type of installation is only possible when

permitted by the laws in force in the appliance’s

country of destination.

• Configuration type B, open chamber and

forced draught.

Using the special coverage kit one can achieve

direct air intake (Fig. 1-10) and fumes exhaust in

a single flue or directly outside. In this configura-

tion it is possible to install the boiler in a partially

protected place. In this configuration the boiler

is classified as type B.

With this configuration:

- air intake takes place directly from the envi-

ronment in which the appliance is installed

(outside);

- the fumes exhaust must be connected to its own

single flue (B

23

) or ducted directly outside via a

vertical terminal for direct exhaust (B

53

) or via

an Immergas ducting system (B

53

).

The technical regulations in force must be

respected.

Flue gas separator adjustment.

For correct

functioning of the boiler in configuration with

direct air intake it is necessary to regulate the flue

gas shutter according to that stated in the relative

tables (page 10).

•

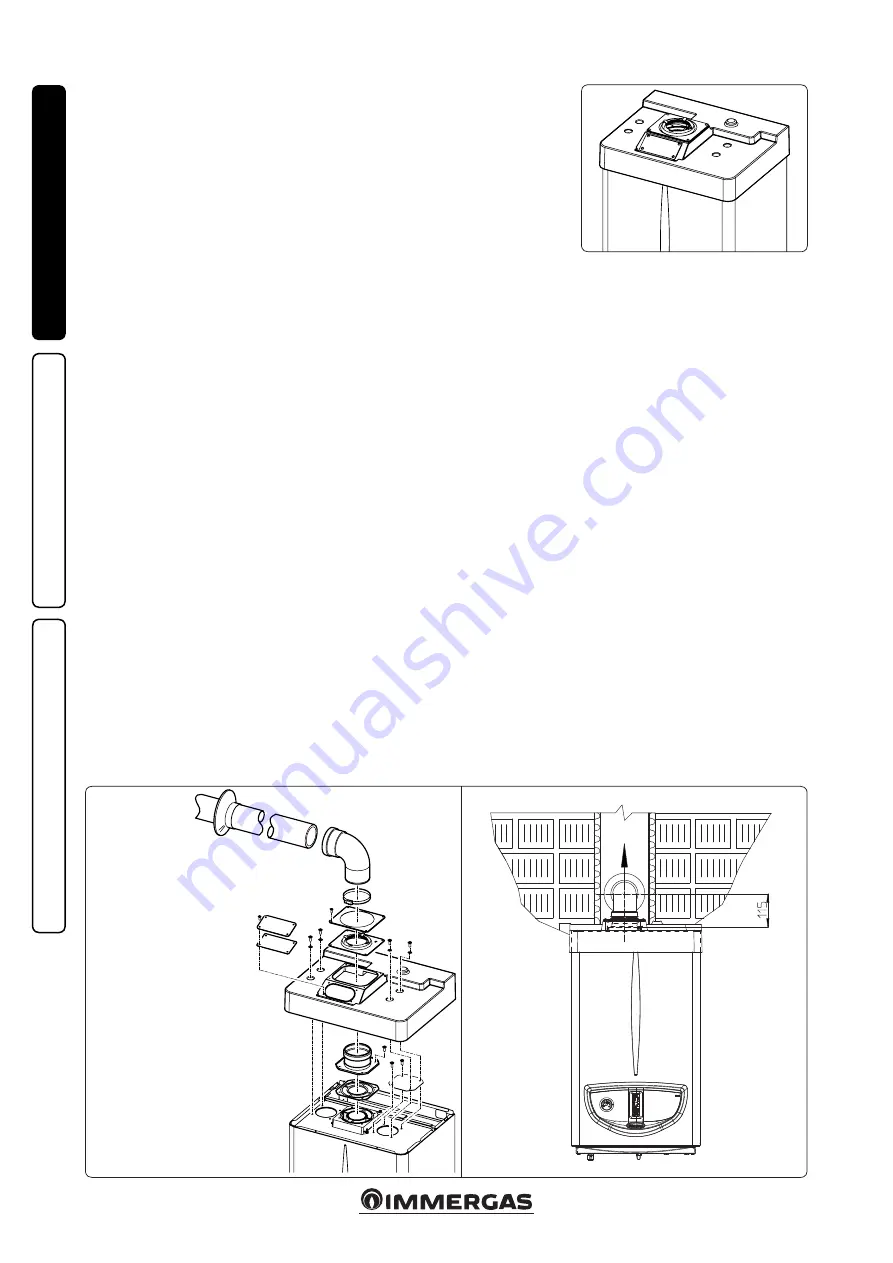

Coverage kit assembly (Fig. 1-11).

Remove

the two plugs and the gaskets present from

the two lateral holes with respect to the central

one. Now cover the right intake hole using the

relevant plate, fixing it onto the left side using

the 2 previously-removed screws. Install the

Ø 80 outlet flange on the central hole of the

boiler, taking care to insert the gasket supplied

with the kit and tighten by means of the screws

provided. Install the upper cover, fixing it using

the 4 screws present in the kit, positioning the

relevant gaskets. Engage the 90° Ø 80 bend with

the male end (smooth) in the female end (with

lip seal) of the Ø 80 flange unit until it stops.

Introduce the gasket, making it run along the

bend. Fix it using the metal sheet plate and

tighten by means of the clips present in the kit,

making sure to block the 4 gasket flaps. Fit the

male end (smooth) of the exhaust terminal into

the the female end of the bend 90° Ø 80, mak-

ing sure that the relevant wall sealing plate is

already fitted; this will ensure hold and joining

of the elements making up the kit.

Max. length of exhaust duct.

The flue pipe

(vertical or horizontal) can be

extended to a

max. length of 12 linear metres, using insulated

pipes (Fig.

1-27). To prevent problems of flue

gas condensate in the exhaust pipe Ø 80, due to

flue gas cooling through the wall,

the length of the

pipe (not insulated) must be limited to just 5 m.

• Configuration without cover kit in a partially

protected location (type C boiler).

By leaving the side plugs fitted, it is possible

to install the appliance externally, in partially

covered places, without the cover kit. Installation

takes place using the Ø 60/100 and Ø 80/125

concentric horizontal intake/ exhaust kits. Refer

to the paragraph relative to indoor installation. In

this configuration the upper cover kit guarantees

additional protection for the boiler. It is recom-

mended but not compulsory.

The cover kit includes:

N° 1 Thermoformed cover

N° 1 Gasket locking plate

N° 1 Gasket

N° 1 Gasket tightening clip

N° 1 Intake hole covering plate

The terminal kit includes:

N° 1 Gasket

N° 1 Discharge flange Ø 80

N° 1 Bend 90° Ø 80

N° 1 Drain pipe Ø 80

N° 1 Wall sealing plate

Summary of Contents for EOLO Maior

Page 1: ...MAIOR EOLO 24 28 32 Instruction and recommendation booklet IE 1 038763ENG ...

Page 2: ......

Page 31: ...31 3 5 6 6 7 8 8 f f e INSTALLER USER MAINTENANCE TECHNICIAN ...

Page 37: ...37 ...

Page 38: ...38 ...

Page 39: ...39 ...