ES

CZ

HU

SL

HR

110

IE

PL

IE

ES

111

CZ

HU

SL

HR

PL

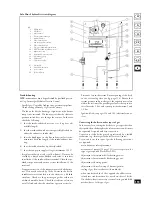

seal) to the end stop on the previously installed to ensure

sealing effi cien cy of the couplings.

• Insulation of separator terminal. In the event of prob lems

of condensation of fl ues inside the ex haust pipes or on the

outside surface of the intake pipes, on request Immergas

supplies insulated in take and exhaust pipes. Insulation

may be nec es sary on exhaust pipes due to excessive drops

in tem per a ture of fl ues during conveyance from the boiler

and on the intake pipes as air on input (cold) may cause

the external pipe temperature lower than the dew point

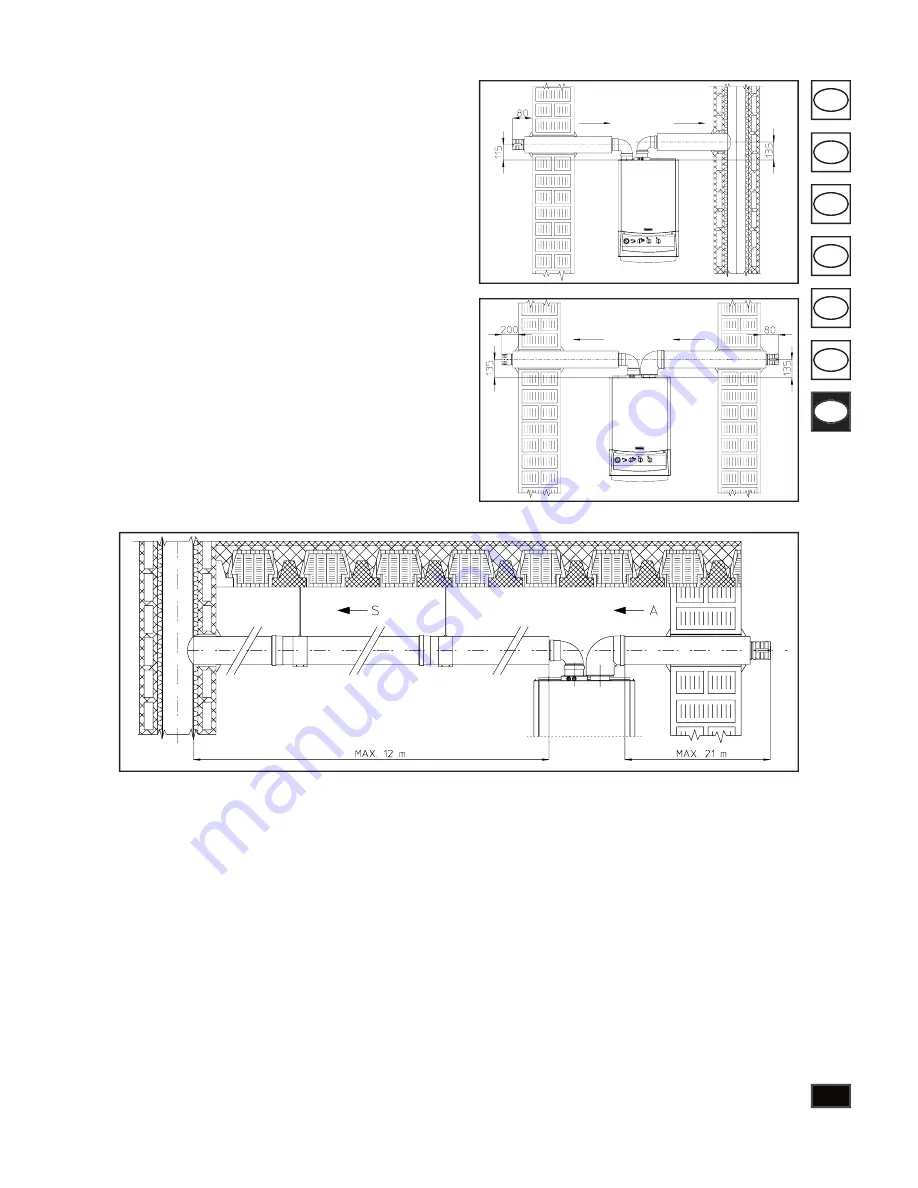

of the ambient air. e fi gures below il lus trate diff erent

applications of insulated pipes.

Insulated pipes comprise an internal Ø 80 con cen tric pipe

and a Ø 125 external pipe with static air jacket. Technically

it is not possible to start with both Ø 80 elbows insula-

ted as clearances will not allow this type of installation.

However an in su lat ed el bow can be used by selecting either

the intake or exhaust pipe. If an insulated intake pipe is

used, the fl ange must be inserted to the end stop on the

fl ue extraction fl ange to ensure that the height of the two

intake and exhaust outlets is aligned.

• Temperature loss in insulated ducting. To avoid the pro-

blem of fl ue condensation in insulated exhaust Ø 80

pipes, due to cooling via the wall,

the ex haust pipe length

must be restricted to 12 me tres.

e fi gure above illustrates

a typical in su la tion ap pli ca tion in which the intake pipe is

short and the ex haust pipe very long (over 5 m). e entire

in take pipe is insulated to prevent condensation of humid

air in the boiler environment in contact with the cooled

pipe conveying cool outdoor air. e entire exhaust pipe

is insulated with the ex cep tion of the elbow on output of

the splitter, to reduce heat dis per sion from the duct and

prevent for ma tion of fl ue condensate.

N.W.:

when installing the insulated ducts, a sec tion clamp

with pin must be installed every 2 me tres.

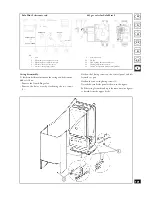

Flue exhaust via fl ues.

Flue exhaust does not necessarily have to be con nect ed a

branched type traditional fl ue and can be connected to a

special LAS type multiple fl ue. Flues must be specially desi-

gned according to spec i fi ca tions in the standard by qualifi ed

pro fes sion al personnel.

Chimney or fl ue sections for connection of the ex haust pipe

must comply with requirements as laid down in standards.

Existing ducting fl ues.

With a specifi c “ducting system” it is possible to re use existing

fl ues, chimneys and technical slots to discharge the boiler

fumes. Ducting requires the use of ducts declared suitable for

the purpose by the manufacturer, following the installation

and op er a tion instructions provided by the manufacturer,

and the requirements standard.