ES

CZ

HU

SL

HR

106

IE

PL

IE

ES

107

CZ

HU

SL

HR

PL

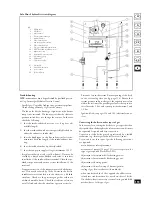

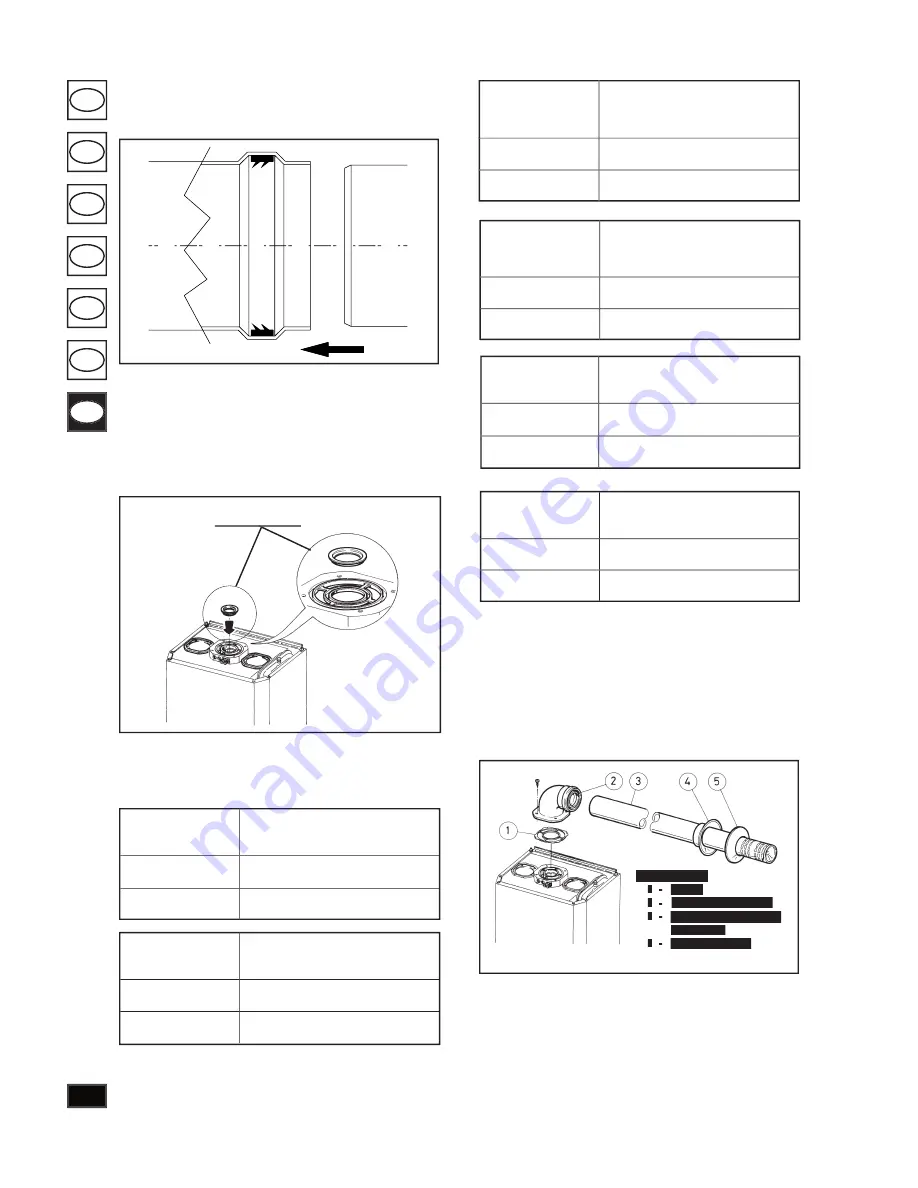

Horizontal intake-exhaust kit Ø60/100.

Kit as sem bly:

install the bend with fl ange (2) on the central hole of the

boiler taking care to insert the seal (1) and secure by means of

the screws supplied with the kit. Join the male end (smooth

section) of ter mi nal pipe (3) to the female section (with lip-

seal) of bend (2) to the end stop and ensure that the in ter nal

and ex ter nal washers are fi tted to achieve per fect seal ing of

all couplings.

• Snap-fi t couplings of concentric pipes or ex ten sions and

elbow fi ttings Ø60/100. To install extension cou plings

on other fl ue extraction components, pro ceed as follows:

fi t the concentric pipe or con cen tric elbow with the male

section (smooth) on the female section (with lip-seal) of

the previously in stalled component to the end stop to

ensure per fect sealing of the coupling.

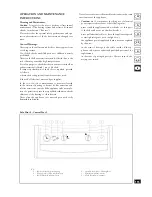

Diaphragm installation.

To ensure correct op er a tion of the

boiler, a diaphragm (see fi gure) must be in stalled on output

of the sealed chamber before the intake and exhaust duct.

Selection of a suitable di a phragm depends on the type of

ducting used and maximum length: calculations can be made

using the values in the tables below:

N.W.:

Diaphragms are supplied as standard with the boi-

ler.

*

e values for maximum length are considered with 1 metre

of exhaust pipe and the remaining on in take.

DIAPHRAGM

Duct length in metres

Ø 60/100 vertical

Ø 41,5

From 0 to 2.7

NONE

Over 2.7

DIAPHRAGM

*Duct length in metres

Ø 80 horizontal duct with two bends

Ø 41,5

NONE

From 0 to 20

Over 20

DIAPHRAGM

Duct length in metres

Ø 60/100 horizontal

Ø 41,5

From 0 to 1

Over 1

NONE

DIAPHRAGM

*Duct length in metres

Ø 80 vertical duct without bends

Ø 41,5

From 0 to 25

NONE

Over 25

DIAPHRAGM

Duct length in metres

Ø 80/125 horizontal

Ø 41,5

NONE

From 0 to 1.9

Over 1,9

DIAPHRAGM

Duct length in metres

Ø 80/125 vertical

Ø 41,5

From 0 to 6.8

NONE

Over 6,8

DIAPHRAGM

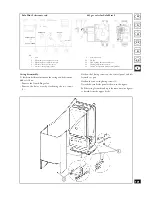

Positioning of double-lip seals.

For correct po si tion ing of

the lip seals on elbows and extensions, follow the order of

assembly shown in the fi gure.

1 - External washer (5)