32

STEMkW Special ed 01/08

EOLO Mini kW Special

Technical Documentation

Technical Documentation

Programming the integrated P.C.B..

If wanted, some of the EOLO Mini kW Special boiler’s para-

meters can be programmed.

By modifying these parameters the boiler can be adapted to

your own specific requirements.

To access programming, put the main selector switch on Reset

for 15 to 20 seconds (LEDs 2 and 3 will start flashing simul-

taneously after about 10 seconds - wait for them to stop and put

the main selector switch on d.h.w. and c.h.).

Now put the main selector switch back on d.h.w.-c.h. (

).

Once programming is activated, you enter the first level where

you can choose the parameter you want to set.

The latter is indicated by the fast flashing of one of the LEDs

between 1 and 8.

Select by turning the d.h.w. temperature knob.

Consult the following table for the LED/parameter associa-

tion:

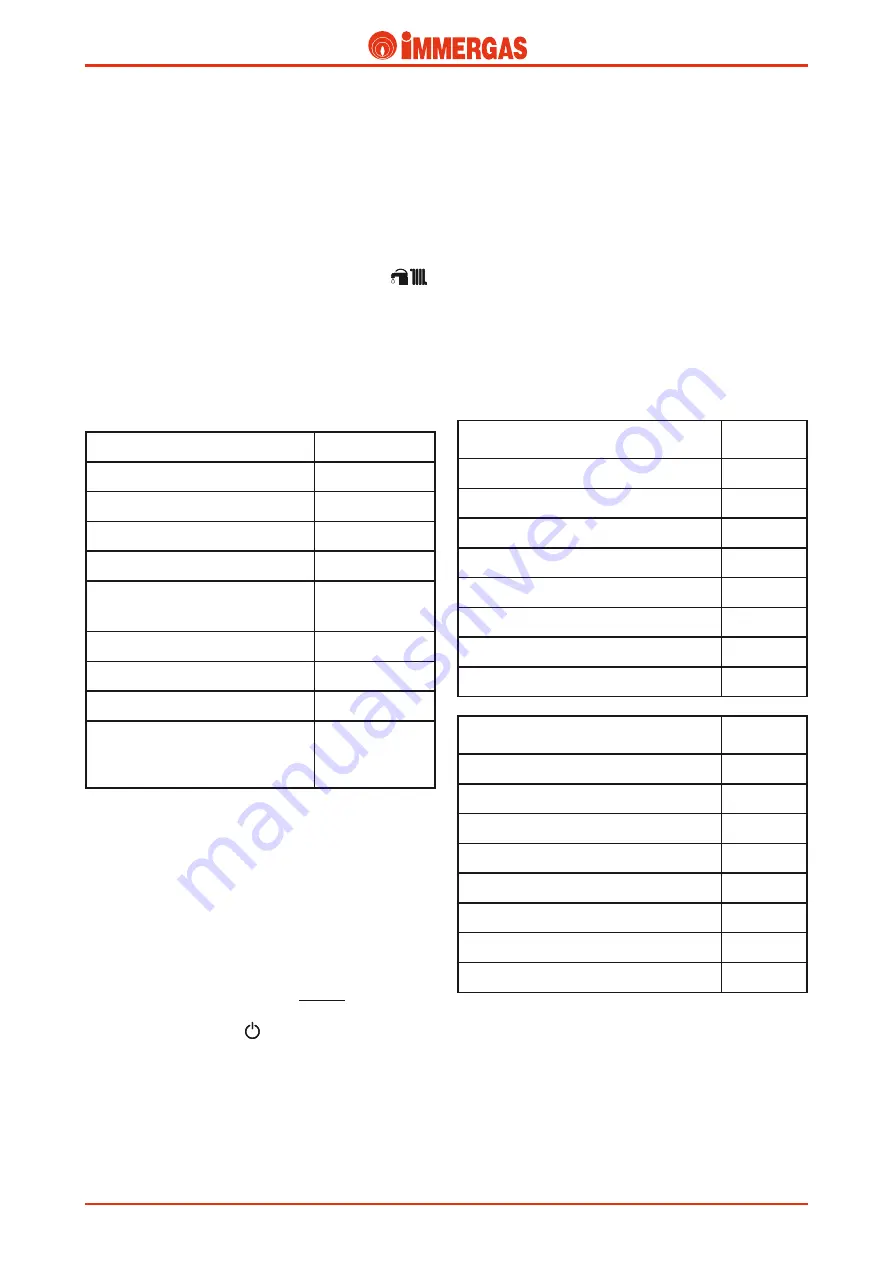

List of parameters

LED flashing (fast)

Minimum heating output

LED 1

Maximum heating output

LED 2

Central heating ignitions timer

LED 3

Central heating output supply ramp

LED 4

Central heating ignitions delayed due

to room thermostat or Remote Control

requests (CAR or CRD)

LED 5

Domestic hot water thermostat

LED 6

Circulator operation

LED 7

Operating gas

LED 8

Boiler mode

(NOT TO BE USED)

(it establishes whether the boiler works in

the instant or storage mode)

Led 8 e 1

Once you have chosen the parameter to change confirm selec-

tion by temporarily turning the main selector switch round to

RESET until the LED relative to the parameter switches off

and then release it.

When the ok has been given for the selection, go to the second

level where the value of the parameter selected can be set.

The value is indicated by the slow flashing of one of the LEDs

between 1 to 8.

The value is selected by turning the central heating tempera-

ture knob.

To exit the programming mode, do nothing for 30 seconds

or, if you are on the “parameter setting” level, put the main

selector switch on position .

For the association of the LED to the value, see the following

tables:

Heating output.

Th e boiler is made and calibrated in the cen-

The boiler is made and calibrated in the cen-

tral heating phase at nominal output. In addition, it features

an electronic adjustment that adapts boiler potential to the

home’s actual heating requirements.

This means that the boiler works normally in a variable field

of gas pressures, ranging from minimum to maximum output

depending on the system’s heating load.

NOTE:

selection of the “Minimum heating output” and

“Maximum heating output” parameters, when there is a cen-

tral heating request, allows boiler ignition and powering of

the modulation with current equal to the value of the relative

parameter selected.

Minimum heating output

(continuous variation)

LED flashing

(slow)

0% Imax. (Standard setting)

LED 1

7% Imax.

LED 2

14% Imax.

LED 3

21% Imax.

LED 4

28% Imax.

LED 5

35% Imax.

LED 6

42% Imax.

LED 7

63% Imax.

LED 8

Maximum heating output

(continuous variation)

LED flashing

(slow)

0% Imax.

LED 1

11% Imax.

LED 2

22% Imax.

LED 3

33% Imax.

LED 4

44% Imax.

LED 5

55% Imax.

LED 6

88% Imax.

LED 7

100% Imax. (Standard setting)

LED 8