22

2-2

INS

TALLER

US

ER

MAINTEN

AN

CE TECHNI

CI

AN

2.5 INFORMATION MENU.

Pressing the buttons (3) and (4) simultaneously

for 3 seconds, the “Information menu” is acti-

vated, which displays some boiler functioning

parameters.

Press buttons (3) and (4) to scroll through the

various parameters. To exit the menu, press

buttons (3) and (4) simultaneously again for 3

seconds or wait for 5 minutes.

List of parameters

Id

Parameter

Description

d1

Displays the flame signal

d2

Displays the primary exchanger

output instant heating flow

temperature (flow probe)

d3

Displays the instant output

temperature from the DHW

exchanger (DHW probe)

d4

Not used

d5

Displays the operating instanta-

neous power (value in %).

d6

Displays the temperature set for

the central heating set (if remote

control is present)

d7

Displays the temperature set for

the DHW set (if remote control

is present)

E1 - E6

Display the anomaly history, of

which E1 is the most recent

Resetting the anomaly history.

Press the Reset button on the information menu

for > 2 seconds and < 4.5 seconds. "E-" will appear

on the display.

Only during this time, if you release the button,

it resets the anomaly history.

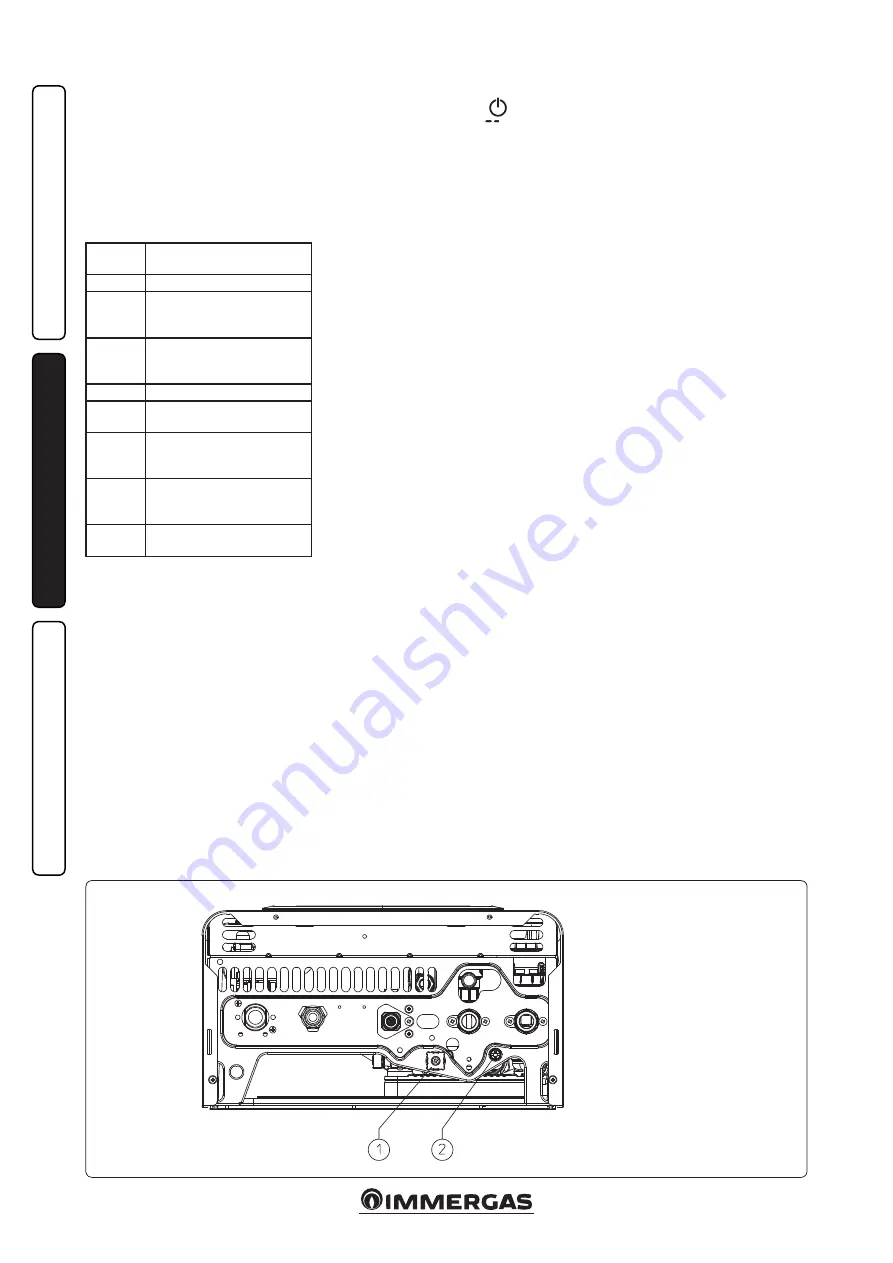

Key:

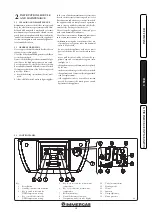

1 - Filling valve

2 - Draining valve

2.6 BOILER SHUTDOWN

Press the button (2 Fig. 2-1) (

) until the

symbol appears on the display ( ).

N.B.:

in these conditions the boiler is still

powered.

Disconnect the omnipolar switch outside the

boiler and close the gas cock upstream of the

appliance. Never leave the boiler switched on if

left unused for prolonged periods.

2.7 RESTORE CENTRAL HEATING

SYSTEM PRESSURE

Periodically check the system water pressure.

The boiler pressure gauge should read a value of

between 1 and 1.2 bar.

If the pressure is below 1 bar (with the circuit cool)

restore normal pressure via the filling cock located

in the lower part of the boiler (Fig. 2-2).

N.B.:

close the cock after the operation.

If pressure values reach around 3 bar the safety

valve may be activated.

In this case, remove water from an air vent valve

of a radiator until reaching pressure of 1 bar, or

ask for assistance from professionally qualified

personnel.

In the event of frequent pressure drops, contact

qualified staff for assistance to eliminate the

possible system leakage.

2.8 DRAINING THE SYSTEM.

To drain the boiler, use the special draining

valve (Fig. 2-2).

Before draining, ensure that the filling cock is

closed.

2.9 ANTIFREEZE PROTECTION.

The boiler comes standard with an antifreeze fun-

ction that activates the pump and burner when

the system water temperature in the boiler falls

below 4°C (standard protection up to the min.

temperature of -5°C) and stops once it exceeds

42°C. The antifreeze function is guaranteed if the

boiler is fully operative and not in “block” status,

and is electrically powered. To avoid keeping

the system switched on in case of a prolonged

absence, the system must be drained completely

or antifreeze substances must be added to the

heating system water. In both cases the boiler

domestic hot water circuit must be drained.

In systems that are drained frequently, filling

must be carried out with suitably treated water

to eliminate hardness that can cause lime-scale.

All information relative to the anti-freeze protec-

tion is stated in Par. 1.3

In order to guarantee the

integrity of the appliance and the domestic hot

water heating system in areas where the tempera-

ture falls below zero, we recommend the central

heating system is protected using anti-freeze

liquid and installation of the

Immergas Anti-

freeze Kit

in the boiler. In the case of prolonged

inactivity (second case), we also recommend that:

- disconnect the electric power supply;

- empty the boiler domestic hot water circuit via

the drain valves (Fig. 1-28) and the internal

domestic hot water distribution network.

2.10 CASE CLEANING.

Use damp cloths and neutral detergent to clean

the boiler casing. Never use abrasive or powder

detergents.

2.11 DECOMMISSIONING.

In the event of permanent shutdown of the boiler,

contact professional staff for the procedures and

ensure that the electrical, water and gas supply

lines are shut off and disconnected.

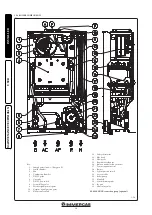

Bottom view.

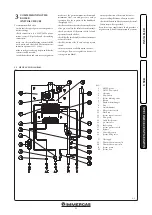

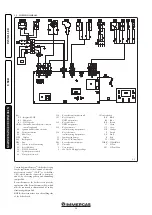

Summary of Contents for EOLO STAR 24 5E

Page 1: ...EOLO STAR 24 5E IE Instructions and warning book 1 040471ENG ...

Page 2: ......

Page 33: ......

Page 34: ......

Page 35: ......