31

INS

TALLER

US

ER

MAINTEN

AN

CE TECHNI

CI

AN

3.4 CONVERTING THE BOILER

TO OTHER TYPES OF GAS.

If the boiler has to be converted to a different

gas type to that specified on the data nameplate,

request the relative conversion kit for quick and

easy conversion.

The gas conversion operation must be carried

out by an authorised company (e.g. Authorised

After-Sales Technical Assistance Service).

To convert to another type of gas the following

operations are required:

- disconnect the appliance;

- replace the nozzle located between the gas pipe

and gas/air mixing sleeve (Part. 16 Fig. 1-27);

- re-power the appliance;

- calibrate the number of fan revolutions (parag.

3.5):

- adjust the correct air/gas ratio (parag. 3.6);

- seal the gas flow rate regulation devices (if set-

tings are modified);

- after completing the conversion, apply the

sticker, contained in the conversion kit, near

the data nameplate. Using an indelible marker

pen, delete the data relative to the old type of

gas.

These adjustments must be made with reference

to the type of gas used, following that given in

the table (Par. 3.18).

3.5 CALIBRATION OF NUMBER OF FAN

REVS.

Attention:

Verification and calibration is neces-

sary, in the case of transformation to other types

of gas, in the extraordinary maintenance phase

with replacement of the PCB air/gas circuit com-

ponents or in the case of installations with fume

extraction systems, with horizontal concentric

pipe measuring more than 1 metre.

The boiler heat output is correlated to the length

of the air intake and flue exhaust pipes. This

decreases with the increase of pipe length. The

boiler leaves the factory adjusted for minimum

pipe length (1m). It is therefore necessary, espe-

cially in the case of maximum pipe extension, to

check the ∆p gas values after at least 5 minutes

of the burner operating at nominal heat output,

when the temperatures of the intake air and ex-

haust flue gas have stabilised. Adjust the nominal

and minimum heat output in the domestic hot

water and central heating modes according to

the values in the table (Par. 3.18) using the dif-

ferential manometers connected to the ∆p gas

pressure points (29 and 30 Fig. 1-27).

Access the configurations menu under the “SER-

VICE” item and adjust the following parameters

(Par. 3.8):

- boiler maximum heat output “P62”;

- boiler minimum heat output “P63”;

- maximum central heating output “P64”;

- minimum central heating output “P65”;

Below find the default settings present on the

boiler:

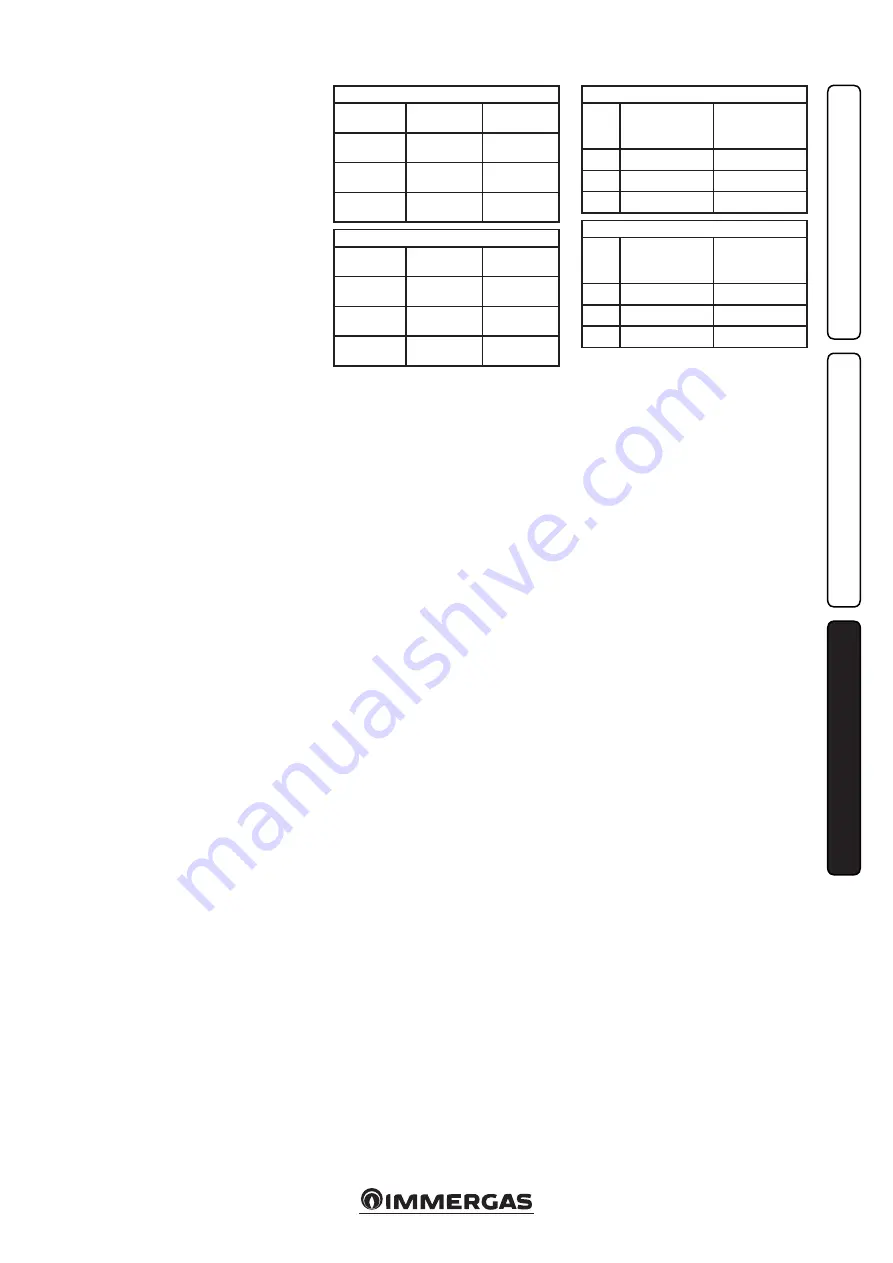

Hercules Condensing 26 3 ErP

P62

G20:

5060 (rpm)

LPG:

4400 (rpm)

P63

G20:

1240 (rpm)

LPG:

1140 (rpm)

P64

G20:

4700 (rpm)

LPG:

4100 (rpm)

P65

G20:

1240 (rpm)

LPG:

1140 (rpm)

Hercules Condensing 32 3 ErP

P62

G20:

4700 (rpm)

LPG:

4200(rpm)

P63

G20:

1260 (rpm)

LPG:

1160 (rpm)

P64

G20:

4700 (rpm)

LPG:

4200 (rpm)

P65

G20:

1260 (rpm)

LPG:

1160 (rpm)

3.6 ADJUSTMENT OF THE AIR-GAS

RATIO.

Calibration of the minimum CO

2

(minimum

central heating power).

Enter the chimney sweep phase without with-

drawing domestic hot water and take the se-

lector switches to minimum (turn them in an

anti-clockwise direction until "0" is seen on the

display). To have an exact value of CO

2

in the flue

gas the technician must insert the sampling probe

to the bottom of the sample point, then check

that the CO

2

value is that specified in the table,

otherwise adjust the screw (3 Fig. 3-3) (Off-Set

adjuster). To increase the CO

2

value, turn the

adjustment screw (3) in a clockwise direction

and vice versa to decrease it.

Calibration of the maximum CO

2

(nominal

central heating power).

On completion of the adjustment of the mini-

mum CO

2

keeping the chimney sweep function

active, take the heating selector switch to maxi-

mum (turn it in a clockwise direction until “99”

is seen on the display). To have an exact value of

CO

2

in the flue gas the technician must insert

the sampling probe to the bottom of the sample

point, then check that the CO

2

value is that speci-

fied in the table, otherwise adjust the screw (12

Fig. 3-3) (gas flow rate regulator).

To increase the CO

2

value, turn the adjustment

screw (12) in an anti-clockwise direction and vice

versa to decrease it.

At every adjustment variation on the screw 12 it

is necessary to wait for the boiler to stabilise itself

at the value set (about 30 sec.).

Hercules Condensing 26 3 ErP

CO

2

at nominal

output

(central heating)

CO

2

at minimum

output

(central heating)

G 20

9.40% ± 0.2

8.90% ± 0.2

G 30

12.00% ± 0.2

11.80% ± 0.2

G 31

10.60% ± 0.2

10.20% ± 0.2

Hercules Condensing 32 3 ErP

CO

2

at nominal

output

(central heating)

CO

2

at minimum

output

(central heating)

G 20

9.40% ± 0.2

8.90% ± 0.2

G 30

12.30% ± 0.2

11.90% ± 0.2

G 31

10.50% ± 0.2

10.30% ± 0.2

3.7 CHECKS FOLLOWING

CONVERSION TO ANOTHER TYPE

OF GAS.

After making sure that conversion was carried

out with a nozzle of suitable diameter for the

type of gas used and the settings are made at the

correct pressure, check that the burner flame is

not too high or low and is stable (does not detach

from burner);

N.B.:

all boiler adjustment operations must be

carried out by a qualified company (e.g. Author-

ised After-Sales Assistance).