18

INS

TALLER

US

ER

MAINTEN

AN

CE TECHNI

CI

AN

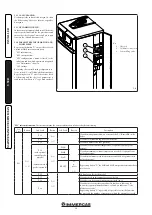

1.18 FLUES, CHIMNEYS, CHIMNEY

POTS AND TERMINALS.

The flues, chimneys and chimney pots for the

evacuation of combustion products must be in

compliance with applicable standards. Chimneys

and roof-installed exhaust terminals must com-

ply with the outlet height and with the distance

from technical volumes set forth by the technical

standards in force.

Positioning the wall flue exhaust terminals.

The

wall flue exhaust terminals must:

- be installed on external perimeter walls of the

building;

- be positioned according to the minimum dis-

tances specified in current technical standards.

Combustion products exhaust of natural

draught or fan assisted appliances in open-top

closed environments.

In spaces closed on all

sides with open tops (ventilation pits, court-

yards etc.), direct combustion product exhaust

is allowed for natural draught or fan assisted gas

appliances with a heat input range from 4 to 35

kW, provided the conditions as per the current

technical standards are respected.

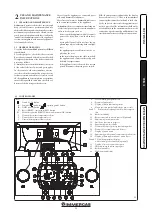

1.19 SYSTEM FILLING.

Once the boiler is connected, proceed with sys-

tem filling via the filling cock (Fig. 2-11). Filling

is performed at low speed to ensure release of air

bubbles in the water via the boiler and central

heating system vents.

The pump may be noisy on start-up due to the

presence of air. This noise should stop after a

few minutes of functioning and however after

having correctly bled the air contained in the

hydraulic circuit.

The boiler incorporates an automatic vent valve

positioned on the boiler pump and one posi-

tioned on the hydraulic manifold.

Make sure

that the hoods are loosened.

Open the radiator

vent valves.

Close radiator vent valves when only water

escapes from them.

Close the filling cock when the boiler pressure

gauge indicates approx. 1.2 bar.

N.B.:

during these operations, turn on the circu-

lating pump at intervals using the main switch

on the control panel.

Vent the circulation pump

by loosening the front cap and keeping the motor

running and assuring that the liquid that escapes

cannot cause injury/damage to persons/objects.

Tighten the cap after the operation.

Attention:

to carry out the filling procedure

correctly, activate the "automatic vent" function,

see paragraph 3.15.

1.20 CONDENSATE TRAP FILLING.

On first lighting of the boiler combustion prod-

ucts may come out the condensate drain; after a

few minutes’ operation check that this no longer

occurs. This means that the trap is filled with

condensate to the correct level preventing the

passage of combustion products.

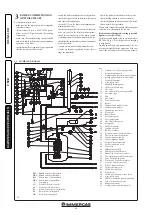

1.21 GAS SYSTEM START-UP.

To start up the system, refer to the technical

standard in force.

In particular, for new gas systems:

- open windows and doors;

- avoid presence of sparks or open flames;

- bleed all air from the pipelines;

- check that the internal system is properly sealed

according to the specifications set forth by

technical regulations in force.

1.22 BOILER START UP (IGNITION).

To commission the boiler (the operations listed

below must only be performed by a qualified firm

and without any unauthorised persons):

- check that the internal system is properly sealed

according to the specifications set forth by

technical regulations in force;

- make sure that the type of gas used corresponds

to boiler settings;

- Check that there are external factors that may

cause the formation of fuel pockets;

- switch the boiler on and check correct ignition;

- make sure that the gas flow rate and relevant

pressure values comply with those given in the

manual (Par. 3.19);

- ensure that the safety device intervenes in the

event of gas supply failure and check the relative

intervention time;

- check the intervention of the main switch

located upstream from the boiler and in the

boiler;

- check that the intake and/or exhaust terminals

(if fitted) are not blocked.

The boiler must not be started up even if only

one of the checks should be negative.