9

1-5

1-6

1-7

45

31

58

INS

TALLER

US

ER

MAINTEN

AN

CE TECHNI

CI

AN

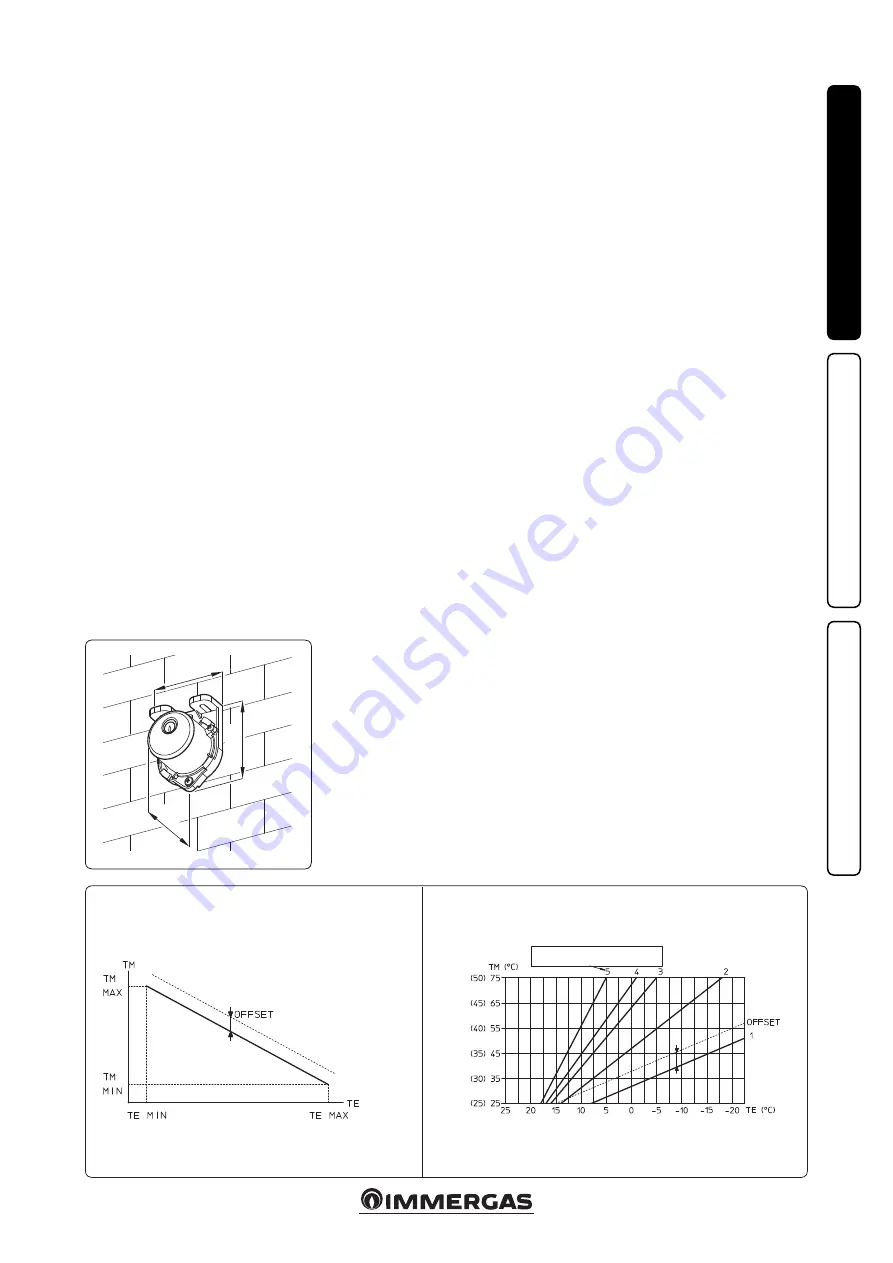

1.7 EXTERNAL TEMPERATURE PROBE

(OPTIONAL).

The boiler is designed for the application of the

Room Thermostat (Fig. 1-5) which is available

as an optional kit. Refer to the relative instruc-

tion sheet to position the external probe. The

probe can be connected directly to the boiler

electrical system and allows the max. system

flow temperature to be automatically decreased

when the external temperature increases, in

order to adjust the heat supplied to the system

according to the change in external tempera-

ture. The external probe always operates when

connected, regardless of the presence or type of

room chrono-thermostat used and can work in

combination with Immergas timer thermostats.

The electric connection of the external probe

must be made on clamps 38 and 39 on the boiler

P.C.B. (Fig. 3-2).

•

Direct Zone Check.

The correlation between

system flow temperature and external tem-

perature is determined by the parameters set in

menu “M5” under item “P66” according to the

curves represented in the diagram (Fig. 1-6).

•

Mixed Zone Check.

The correlation between

flow temperature to the system and external

temperature is determined by the position of

the trimmer (16 Fig. 3-5) on the zone board ac-

cording to the curve represented in the diagram

(Fig. 1-7).

TM - MAX/MIN = Direct temperature zone flow temperature

range selected.

TE = External temperature.

Direct Zone

Correction law of the flow temperature depending on the external tem-

perature and user adjustments of the central heating temperature.

Mixed Zone

Correction law of the flow temperature depending on the external temperature and

user adjustments of the central heating temperature.

TM = Mixed zone flow temperature

TE = External temperature.

POSITION OF THE TRIMMER

ZONE P.C.B.

In brackets, temperature value with 25°/50° range