33

3-2

1

5

2

3

4

6

7

10

9

8

CH ON

INS

TALLER

US

ER

MAINTEN

AN

CE TECHNI

CI

AN

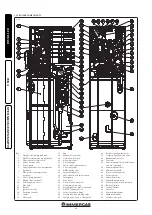

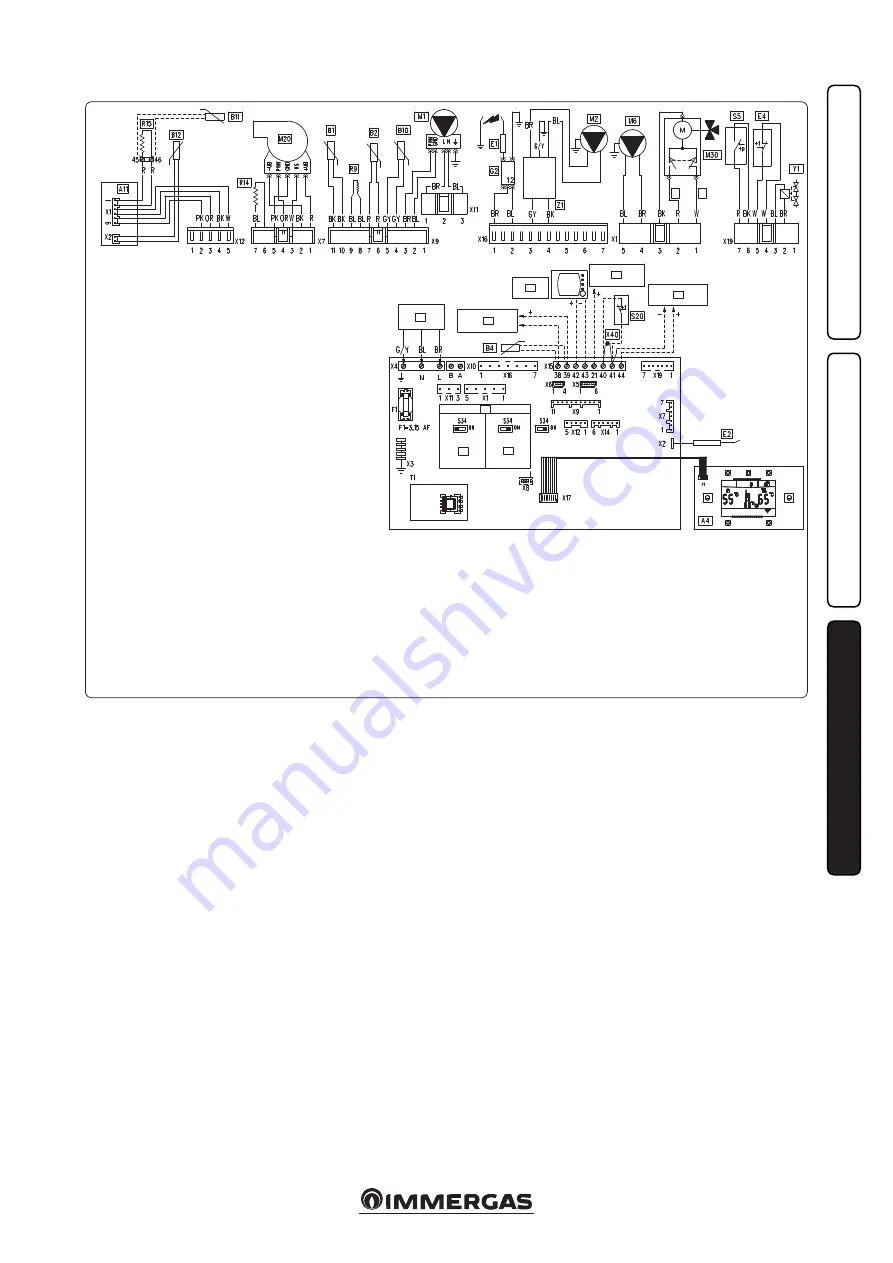

Key:

A4 - Display board

A10 - Pump relay board

A11 - Interface board PT1000

B1 - Flow probe

B2 - Domestic hot water probe

B4 - External probe (optional)

B10 - Flue probe

B11 - Solar collector probe (PT1000)

B12 - Storage tank solar probe

E1 - Ignition electrodes

E2 - Detection electrode

E4 - Safety thermostat

F1 - Phase fuse

G2 - Igniter

M1 - Boiler circulator pump

M2 - Central heating pump

M6 - Solar circuit circulator

M20 - Fan

M30 - Three-way valve

R9 - Return probe unabling resistance

R14 - Solar configuration resistance

R15 - Solar collector probe unabling

resistance

S5 - System pressure switch

S20 - Room thermostat (optional)

T1 - Boiler PCB transformer

X40 - Room thermostat jumper

Y1 - Gas valve

Z1 - Antijamming filter

BK - Black

BL - Blue

BR - Brown

G - Green

GY - Grey

G/Y - Green-Yellow

OR - Orange

P - Purple

PK - Pink

R - Red

W - White

Y - Yellow

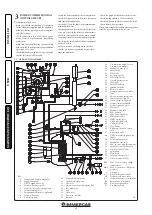

Remote controls: the boiler is designed for use

with the Comando Amico Remoto remote

control

V2

(CAR

V2

) or alternatively the Super

Comando Amico Remoto remote control, which

must be connected to clamps 42 and 43 of con-

nector X15 on the P.C.B., observing polarity and

eliminating jumper X40.

Room thermostat: the boiler is designed for the

application of the Room Thermostat (S20). Con-

nect it to clamps 40 – 41 eliminating jumper X40.

The connector X5 is used for the connection to

the relay board.

The connector X6 is for connection to a personal

computer.

The connector X8 is used for software updating

operations.

Solar collector probe: the boiler is set-up for the

connection to a solar panel system; the probe

must be connected to clamps 45 and 46, eliminat-

ing resistance R15.

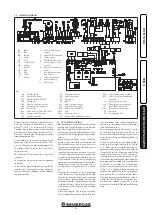

3.3 TROUBLESHOOTING.

N.B.:

maintenance operations must be carried

out by an authorised company (e.g. Authorised

After-Sales Technical Assistance Service).

- Smell of gas. Caused by leakage from gas circuit

pipelines. Check sealing efficiency of gas intake

circuit.

- Repeated ignition blocks. No gas, check the

presence of pressure in the network and that

the gas adduction cock is open. Incorrect

adjustment of the gas cock, check the correct

calibration of the gas valve.

- Irregular combustion or noisiness. It may be

caused by: a dirty burner, incorrect combustion

parameters, intake-exhaust terminal not cor-

rectly installed. Clean the above components

and ensure correct installation of the terminal,

check correct setting of the gas valve (Off-Set

setting) and correct percentage of CO

2

in flue

gas.

- Frequent interventions of the overheating

safety thermostat. It can depend on the lack

of water in the boiler, little water circulation

in the system or blocked pump. Check on the

manometer that the system pressure is within

established limits. Check that the radiator

valves are not closed and also the functionality

of the pump.

- Drain trap clogged. This may be caused by

dirt or combustion products deposited inside.

Check, by means of the condensate drain cap,

that there are no residues of material blocking

the flow of condensate.

- Heat exchanger clogged. This may be caused

by the drain trap being blocked. Check, by

means of the condensate drain cap, that there

are no residues of material blocking the flow of

condensate.

- Noise due to air in the system. Check opening

of the special air vent valve cap (Part. 39 Fig.

1-33). Make sure the system pressure and ex-

pansion vessel pre-charge values are within the

set limits; The factory-set pressure values of the

expansion vessel must be 1.0 bar, the value of

system pressure must be between 1 and 1.2 bar.

Check that system filling and air bleeding has

been performed according to the requirements.

- Noise due to air inside the condensation

module. Use the manual air vent valve (Part.

38 Fig. 1-33) to eliminate any air present in the

condensation module. When the operation has

been performed, close the manual vent valve.

- Domestic hot water probe faulty. In order to

replace the DHW probe, the storage tank does

not have to be emptied as the probe is not in

direct contact with the DHW inside the storage

tank.

3.2 WIRING DIAGRAM.

1 - 230 Vac 50 Hz power

supply

2 - Super CAR (Optional)

3 - Status signal

4 - IMG BUS connection

5 - System supervisor con-

nection

6 - Supervisor connection

active

7 - External probe connec-

tion active

8 - Domestic hot water

9 - Central heating

10 - S34 setting