16

Installation

TECHNICAL FEATURES

The flue that services a pellet device must meet the following

requirements:

• be made with materials that can withstand mechanical

stress, heat, action of combustion products and their

condensate over time.

• be made with waterproof materials against flue gas,

condensate, thermally insulated and suitable to withstand

normal mechanical stress over time

• have a vertical performance with axis deviations not

exceeding 45° and without constrictions

• Must be suitable for specific operating conditions of

the product and provided with CE marking (EN1856-1,

EN1443).

• Be sized correctly in order to meet the flue gas draught/

disposal required to regulate product operation (EN13384-1)

• Be adequately insulated to prevent condensate and reduce

the effect of flue cooling.

• Must be minimum category T400 and withstand soot fire.

In particular, it is recommended to check the data plate of the

flue (according to EN1856-1, EN1443) for the safety distances

that must be respected in the presence of or passing through

of combustion materials and the type of insulating material to

use. These provisions must be strictly complied with in order

to prevent serious harm to one’s health and safeguard the

integrity of the building.

The chimney’s opening must be in the same room in which

the appliance is installed or, at most, in the adjacent room, and

to install a soot and condensate collection chamber under the

opening, which can be accessed from the metal sealed door.

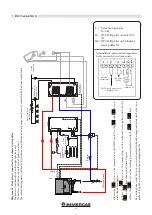

DIMENSIONING

The negative pressure (draught) of a flue also depends on its

height.

Use suitable tools to check that draught is between 8 Pa and

15 Pa.

The internal section of the flue can be round (it is the best),

square or rectangle (the ratio between the internal sides must

be ≤1.5) with the sides connected with a minimum 20 mm

radius.

The sections/lengths of the chimneys listed in the technical data

table are indications for correct installation. Any alternative

configurations must be correctly dimensioned according to

the general calculation method regarding UNI EN13384-1 or

other approved efficiency methods.

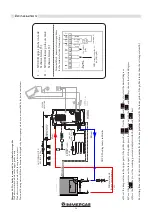

Below are a few examples of flues available on the market:

AISI 316 steel

chimney with

double insulated

chamber with

ceramic fibre

or equivalent

resistance up to

400°C.

Refractory

chimney with

double insulating

chamber and

external sleeve

in lightweight

concrete made

from a clay type

of honeycomb

material.

Traditional square

clay chimney with

empty insulating

inserts.

Avoid chimneys

with internal

rectangular

sections whose

ratio between

the largest and

smallest side is

greater than 1.5

(e.g. 20x40 or

15x30).

VERY GOOD

GOOD

AVERAGE

POOR