3-1

29 - IE

INS

TALLER

US

ER

MAINTEN

AN

CE TECHNI

CI

AN

3

BOILER START-UP

(INITIAL CHECK).

To commission the boiler:

- make sure that the declaration of conformity

for installation is supplied with the appliance;

- make sure that the type of gas used corresponds

to boiler settings;

- check connection to a 230V-50Hz power

mains, correct L-N polarity and the earthing

connection;

- make sure the central heating system is filled

with water and that the manometer indicates

a pressure of 1÷1.2 bar;

- check that the heat pump is connected and

powered properly (see relative instructions

manual);

- check that the common parameters between

the heat pump and the boiler are configured

properly;

- switch the boiler on and check correct ignition;

- check the ∆p gas values in domestic hot water

and central heating modes;

- check the CO

2

in the fumes at maximum and

minimum flow rate;

- check activation of the safety device in the event

of no gas, as well as the relative activation time;

- check the intervention of the main switch

located upstream of the boiler and in the boiler;

- check that the intake and/or exhaust terminals

are not blocked;

- ensure activation of all adjustment devices;

- seal the gas flow rate regulation devices (if

settings are modified);

- check the production of domestic hot water;

- check sealing efficiency of water circuits;

- check ventilation and/or aeration of the

installation room where provided.

If even only a single safety check offers a negative

result, do not commission the system.

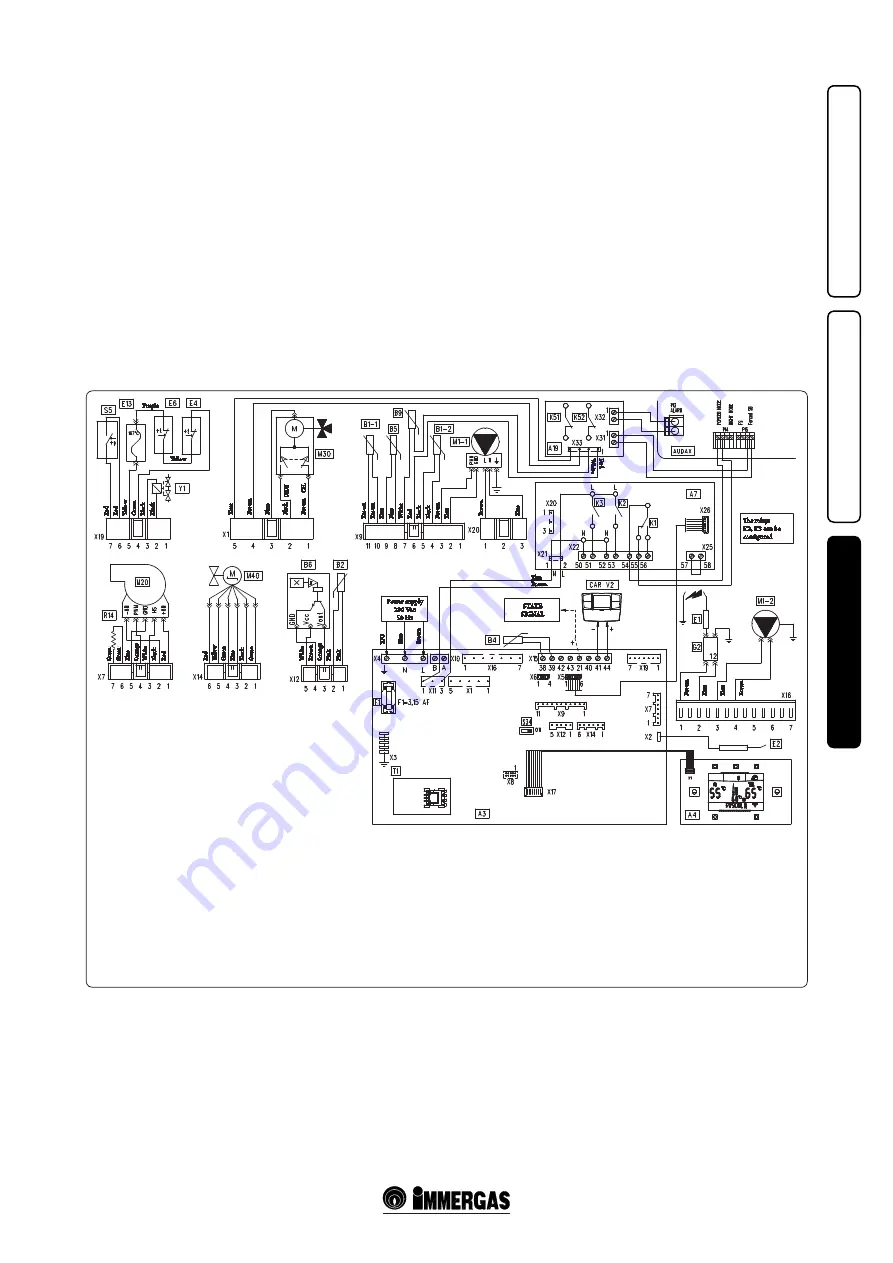

3.1 WIRING DIAGRAM.

The connector X6 is for connection to a personal

computer.

The connector X8 is used for software updating

operations.

Selector S34 defines boiler operation with the

external probe and must always be set = On.

M30 - Three-way valve

M40 - Domestic flow rate regulator

S5 - System pressure switch

S20 - Room thermostat (optional)

S34 - System supervisor connection

selector

R14 - Boiler configuration resistance

T1 - Low voltage power supply unit

Y1 - Gas valve

Key:

A3 - Integrated P.C.B

A4 - Display board

A7 - Relay P.C.B.

A19 - Relay P.C.B. 2

B1-1 - Boiler flow probe

B1-2 - System flow probe

B2 - Domestic hot water probe

B4 - External probe

B5 - Return probe

B6 - Domestic hot water flow meter

B9 - Domestic hot water inlet probe

CAR

V2

- Comando Amico Remoto remote

control

V2

E1 - Ignition electrodes

E2 - Detection electrode

E4 - Safety thermostat

E6 - Flue safety thermostat

E13 - Heat exchanger safety thermofuse

F1 - Phase fuse

G2 - Igniter

K1 - Heating / cooling selector relay

K51 - Stand-by / on forcing relay

K52 - Anomaly relay

M1-1 - Boiler circulator pump

M1-2 - System circulator pump

M20 - Fan

Yellow

Purple

Re

d

Gr

een

Gr

een

Bl

ue

Ora

ng

e

W

hi

te

Bl

ac

k

Re

d

Re

d

Ye

llo

w

G

re

en

G

re

en

Bl

ue

Bl

ue

Br

ow

n

Bl

ue

Bl

ac

k

Br

ow

n

Br

ow

n

Br

ow

n

Bl

ue

Bl

ue

W

hi

te

Re

d

Bl

ac

k

Bl

ac

k

Br

ow

n

Br

ow

n

Y/G

Bl

ue

Br

ow

n

Br

ow

n

Bl

ue

Bl

ue

Br

ow

n

Brown

Blue

Bl

ue

W

hi

te

Re

d

The relays

K2, K3 can be

configured

STATE

SIGNAL

Power supply

230 Vac

50 Hz

Bl

ue

CH.

DHW

Bl

ac

k

W

hi

te

Br

ow

n

Ora

ng

e

Pin

k

Pin

k

Re

d

Ye

llo

w

G

re

en

Bl

ac

k

Bl

ac

k

Summary of Contents for MAGIS Victrix

Page 1: ...MAGIS Victrix IE Instruction and warning book 1 035518ENG ...

Page 2: ......

Page 42: ......

Page 43: ......