23

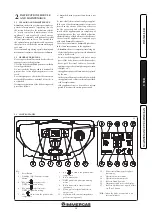

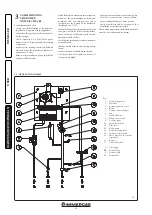

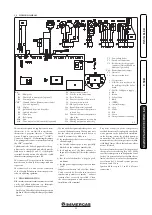

3-2

5

1

2

6

5

4

3

4

4

5

11

7

7

7

12

12

7

13

13

11

4

5

5

7

4

10

10

9

8

14

INS

TALLER

US

ER

MAINTEN

AN

CE TECHNI

CI

AN

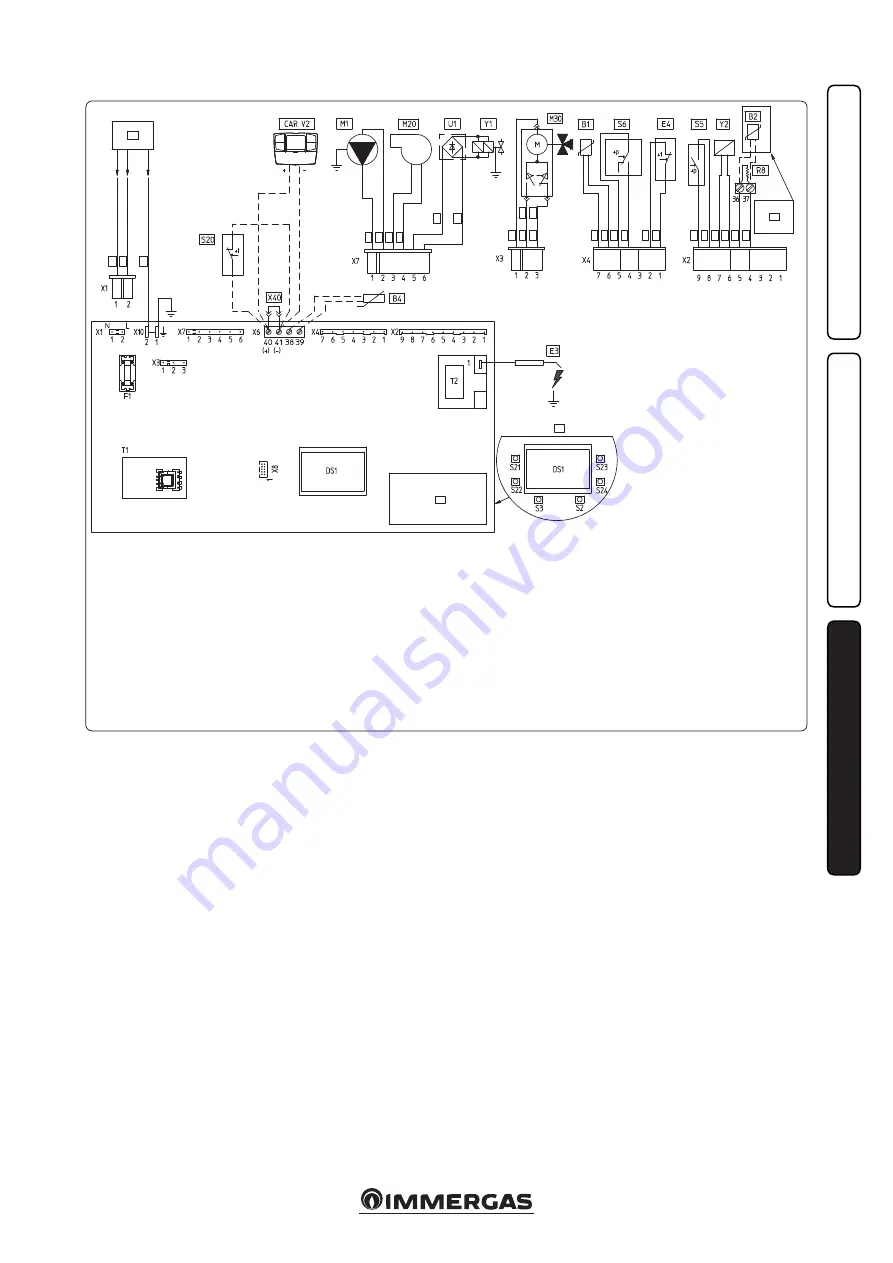

3.2 WIRING DIAGRAM.

The boiler is designed for application of a room

thermostat (S20), an On/Off room chrono-

thermostat, a program timer or a Comando

Amico Remoto remote control

V2

(CAR

V2

).

Connect to clamps 40 - 41 eliminating the jumper

X40, paying attention not to invert the polarity if

the CAR

V2

is installed.

Cylinder unit: the boiler is prepared for the ap-

plication of a storage tank unit, which must be

connected to clamps 36 and 37 of the bipolar

terminal board positioned under the sealed

chamber, eliminating resistance R8.

The connector X3 is present in the boiler but

must be connected only if the storage tank unit

is present.

The connector X8 is used for the connection

of the Virgilio Palmtop in the microprocessor

software updating operation.

3.3 TROUBLESHOOTING

N.B.:

maintenance interventions must be carried

out by a qualified technician (e.g. Immergas

After-Sales Technical Assistance Service).

- Smell of gas. Caused by leakage from gas circuit

pipelines. Check sealing efficiency of gas intake

circuit.

- The fan works but ignition discharge does not

occur on the burner ramp. The fan may start

but the safety air pressure switch does not

switch the contact over. Make sure:

1) the intake-exhaust duct is not too long (over

allowed length).

2) the intake-exhaust pipe is not partially

blocked (on the exhaust or intake side).

3) the diaphragm of the fume exhaust is

adequate for the length of the intake-exhaust

duct.

4) that the sealed chamber is kept in good

conditions.

5) the fan power supply voltage is not less than

196 V.

- Irregular combustion (red or yellow flame).

Can be caused by: dirty burner, incorrect

combustion parameters, intake - exhaust

terminal not correctly installed. Clean

the above components and ensure correct

installation of the terminal.

- Frequent activation of the temperature

overload thermostat. It can depend on reduced

water pressure in the boiler, little circulation

in the heating system, the blocked pump or

an anomaly of the boiler P.C.B. Check on the

manometer that the system pressure is within

established limits. Check that radiator valves

are not all closed.

- Presence of air in the system. Check opening of

the special air vent valve cap (Fig. 1-30). Make

sure the system pressure and expansion vessel

factory-set pressure values are within the set

limits; the factory-set value for the expansion

vessel must be 1.0 bar, and system pressure

between 1 and 1.2 bar.

- Ignition block see par. 2.5 and 1.4 (electric

connection).

Key:

B1 - Flow probe

B2 - Domestic hot water probe (optional)

B4 - External probe

CAR

V2

- Comando Amico Remoto remote control

Version 2 (optional)

DS1 - Display

E3 - Ignition and detection electrodes

E4 - Safety thermostat

F1 - Phase fuse

M1 - Boiler pump

M20 - Fan

M30 - Three-way valve (disconnected) (optional)

R8 - Storage tank resistance

S2 - Selector switch functioning

S3 - Reset block keys

S4 - Domestic hot water flow switch

S5 - System pressure switch

S6 - Flue gas pressure switch

S20 - Room thermostat (optional)

S21 - Domestic hot water temperature

increase key

S22 - Domestic hot water temperature

reduce key

S23 - Heating temperature increase key

S24 - Heating temperature reduce key

T1 - Low voltage feeder

T2 - Switch-on transformer

U1 - Rectifier inside the gas valve

connector (Only available on

Honeywell gas valves)

X40 - Room thermostat jumper

Y1 - Gas valve

Y2 - Gas valve modulator

1 - User interface

2 - N.B.: The user interface is on

the welding side of the boiler

board

3 - 230 Vac 50Hz power supply

4 - Blue

5 - Brown

6 - Yellow/Green

7 - Black

8 - (DHW)

9 - (central heating)

10 - Grey

11 - White

12 - Red

13 - Green

14 - Storage tank unit (optional)

Summary of Contents for MINI NIKE X 24 3 E

Page 1: ...MINI EOLO X 24 3 E Instruction and recommendation booklet IE 1 038775ENG ...

Page 2: ......

Page 28: ...28 3 5 4 4 5 6 6 d d c INSTALLER USER MAINTENANCE TECHNICIAN ...

Page 33: ......

Page 34: ......

Page 35: ......