12

C12

1-13

C12

C12

C12

C12

1-14

1-16

1-17

1-15

1

3

2

4 5

INS

TALLER

US

ER

MAINTEN

AN

CE TECHNI

CI

AN

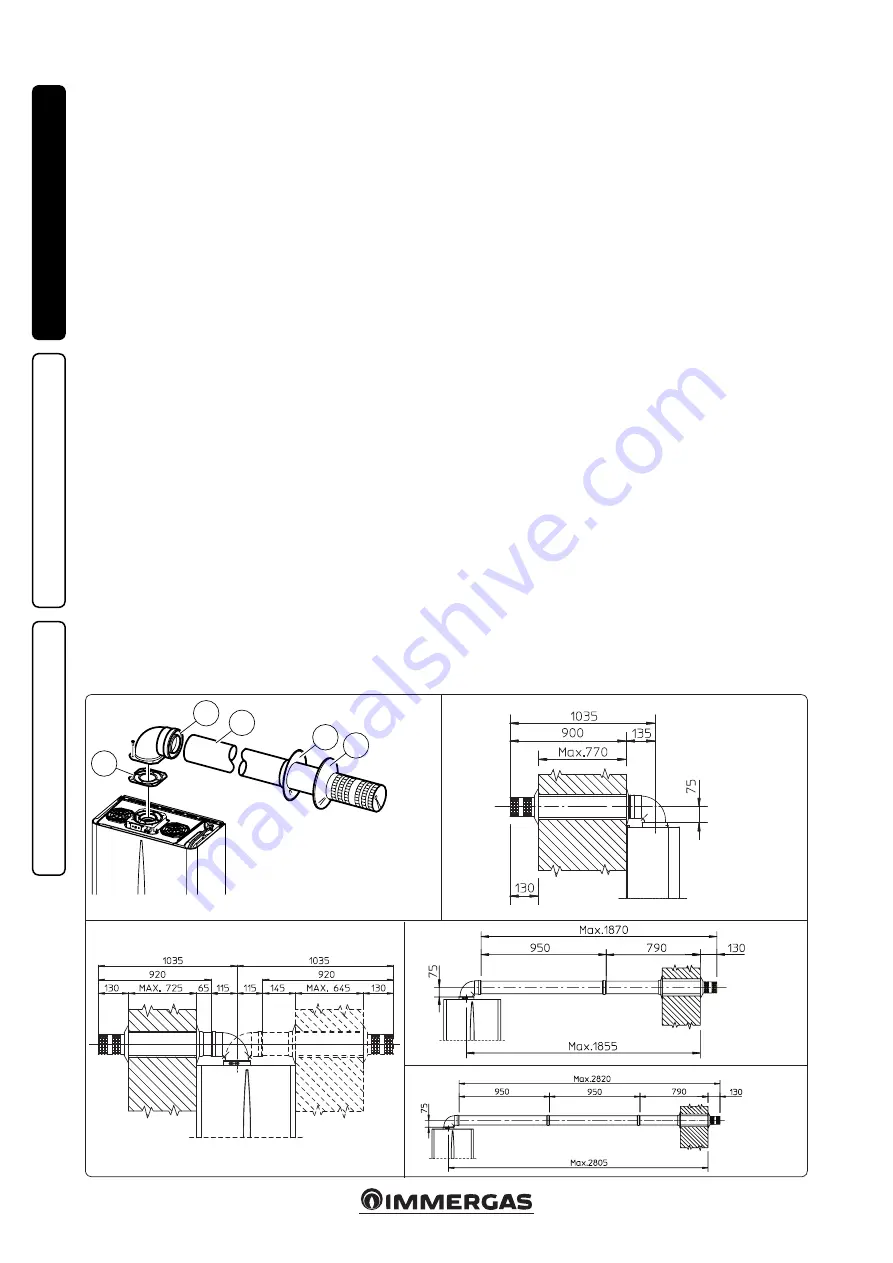

The kit includes:

N°1 - Gasket (1)

N°1 - Concentric bend 90° (2)

N°1 - Intake/Exhaust concentric pipe

Ø60/100 (3)

N°1 - Internal wall sealing plate (4)

N°1 - External wall sealing plate (5)

1.10 CONCENTRIC HORIZONTAL KIT

INSTALLATION.

Type C configuration, sealed chamber and

fan assisted.

Installation of this terminal is governed by

standards contained in local building regulations,

as amended.

N.B.:

in addition to the traditional “Ø60/100

horizontal kit” there is also a specific “Ø60/100

Star” version, with the same measurements and

equivalent head loss.

This terminal is connected directly to the outside

of the building for air intake and flue exhaust. The

horizontal kit Ø 60/100 can be installed with the

rear, right side, left side or front outlet.

• External grid.

N.B.:

for safety purposes, do not

obstruct the boiler intake-exhaust terminal,

even temporarily.

Horizontal intake - exhaust kit Ø60/100.

Kit assembly (Fig. 1-13): install the bend with

flange (2) onto the central hole of the boiler

inserting the gasket (1) and tighten using the

screws included in the kit. Couple the terminal

pipe (3) with the male end (smooth) into the

female end of the bend (with lip seals) up to the

stop; making sure that the internal wall sealing

plate and external wall sealing plate have been

fitted, this will ensure sealing and joining of the

elements making up the kit.

• Application with rear outlet (Fig. 1-14). The

970 mm pipe length enables routing through

a maximum thickness of 770 mm. Normally

the terminal must be shortened. Calculate

the measurement by the sum of these values:

Wall thi indoor ext outdoor

extension. The minimum indispensable

projection values are given in the figure.

• Application with side outlet (Fig. 1-15). Using

the horizontal intake-exhaust kit, without the

special extensions, enables routing through

a wall thickness of 725 mm with the left side

outlet and 645 with the right side outlet.

• Extensions for horizontal kit. The Ø 60/100

horizontal intake-exhaust kit can be extended

up

to a max. horizontal length of 3000 mm

,

including the terminal with grille and excluding

the concentric bend leaving the boiler. This

configuration corresponds to a resistance factor

of 100. In these cases the special extensions

must be requested.

Connection with 1 extension (Fig. 1-16).

Max. distance between vertical boiler axis and

external wall is 1855mm.

Connection with 2 extensions (Fig. 1-17).

Max. distance between vertical boiler axis and

external wall is 2805mm.

Horizontal intake - exhaust kit Ø80/125.

Kit

assembly (Fig. 1-18): install the bend with flange

(2) onto the central hole of the boiler inserting

the gasket (1) and tighten using the screws

included in the kit. Fit the male end (smooth) of

the adapter (3) up to the end stop on the female

side of the bend (2) (with lip seal). Fit the Ø

80/125 (4) concentric terminal pipe with the male

end (smooth) to the female end of the adapter (3)

(with lip gasket) up to the stop; making sure that

the internal and external wall sealing plates have

been fitted; this will ensure sealing and joining

of the elements making up the kit.

Normally the horizontal intake/exhaust kit Ø

80/125 is used if particularly long extensions

are required.

• Extensions for horizontal kit. The Ø 80/125

horizontal intake-exhaust kit can be extended

up to a

max. horizontal distance of 7,300 mm

including the terminal with grid and excluding

the concentric bend leaving the boiler and the

adapter Ø 60/100 in Ø 80/125 (Fig. 1-19). This

configuration corresponds to a resistance factor

of 100. In these cases the special extensions

must be requested.

N.B.:

when installing the pipes, a section clamp

with pin must be installed every 3 metres.

Summary of Contents for MINI NIKE X 24 3 E

Page 1: ...MINI EOLO X 24 3 E Instruction and recommendation booklet IE 1 038775ENG ...

Page 2: ......

Page 28: ...28 3 5 4 4 5 6 6 d d c INSTALLER USER MAINTENANCE TECHNICIAN ...

Page 33: ......

Page 34: ......

Page 35: ......