20

INS

TALLER

US

ER

MAINTEN

AN

CE TECHNI

CI

AN

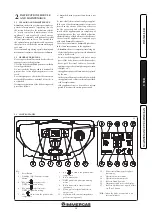

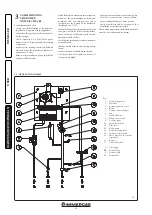

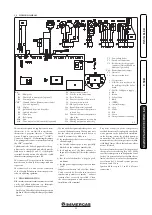

2.4 USING THE BOILER.

Important:

the Mini Eolo X 24 3 E boiler has

been designed to operate as an appliance for

room central heating only or, coupled to a specific

optional kit, for central heating and the produc-

tion of DHW. For this reason the boiler control

panel has a button to adjust the temperature of

DHW, but its operation is only activated by the

optional kits that also enable the production of

DHW. Without the coupling of these specific kits,

the functioning of this button and all functions

referring to the DHW are inhibited.

Before ignition make sure the heating system

is filled with water and that the manometer (7)

indicates a pressure of 1 ÷ 1.2 bar.

- Open the gas cock upstream from the boiler.

- Press the button (2) until the display switches

on, after which press the button in sequence

(2) and take the boiler to the summer (

)

or winter (

) position.

•

Summer

(

)

:

in this mode the boiler

functions only to produce the DHW

(when the

boiler is connected to an external cylinder)

, the

temperature is set via the buttons (3-4) and the

relative temperature is shown on the display via

the indicator (16).

• Winter

(

)

:

in this mode the boiler functions

both for producing domestic hot water

(when

the boiler is connected to an external cylinder)

and heating the environment. The temperature

of the DHW is always regulated via buttons

(3-4), the heating temperature is regulated via

buttons (5-6) and the relative temperature is

shown on the display via the indicator (16).

From this moment the boiler functions

automatically. With no demand for heat (heating

or domestic hot water production) the boiler

goes to “standby” function, equivalent to the

boiler being powered without presence of flame.

Each time the burner ignites, the relative flame

present symbol is displayed (10) with relative

output scale.

•

Operation with Comando Amico Remoto

V2

(CAR

V2

) (Optional)

. If the CAR

V2

is connected,

the (

) symbol will appear on the display.

The boiler regulation parameters can be set

via the CAR

V2

control panel and the reset

button (1) remains active on the boiler control

panel, along with the switch-off button (2)

(“off” mode only) and the display where the

functioning state is shown.

Attention:

if the boiler is put into "off" mode,

the “ERR>CM” connection error symbol

will appear on the CARCAR

V2

. The CAR

V2

is

however powered constantly so as not to loose

memorised programs.

•

Operation with optional external probe

(

)

.

In the case of a system with optional

external probe, the boiler flow temperature

for room central heating is managed by the

external probe depending on the external

temperature measured (Par. 1.6). The flow

temperature can be modified by selecting

the functioning curve via buttons (5 and 6),

selecting a value from "0 to 9" (Fig. 1-6).

With external probe present, the relative

symbol (12) will appear on the display. In the

central heating phase, if the temperature of the

water contained in the system is sufficient to

heat the radiators, the boiler can only function

with the activation of the pump.

•

“Stand-by” mode.

Press button (2) in

succession until the (

) symbol appears.

The boiler remains active from this moment

and the anti-freeze function, pump anti-block

function and 3-way and signalling of any

anomalies is guaranteed.

N.B.:

in these conditions the boiler is

considered still powered.

•

“Off” mode.

By holding the button (2) down

for 8 seconds, the display switches-off and the

boiler is off completely. The safety functions are

not guaranteed in this mode.

N.B.:

in these conditions the boiler is considered

still live even if there are no functions active.

•

Display functioning.

The display lights up

during the use of the control panel, after 15

seconds inactivity, the brightness drops until

just the active symbols are displayed. The

lighting mode can be varied via parameter P2

in the circuit board customisation menu.

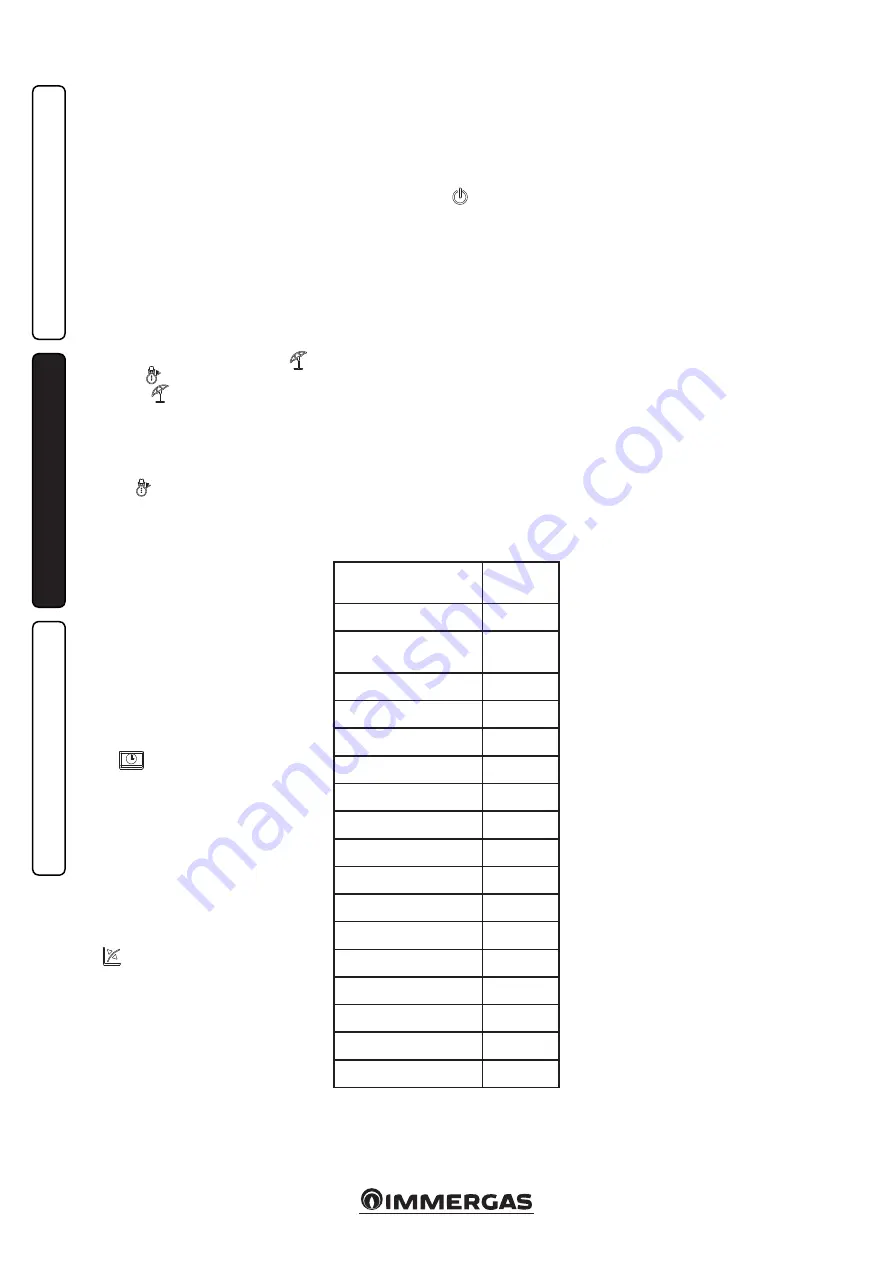

2.5 FAULT AND ANOMALY SIGNALS.

The boiler signals out anomalies by flashing on

the display and relative error codes, listed on the

table, are displayed.

Anomaly signalled

code

displayed

(flashing)

No ignition block

01

Safety thermostat block

(overheating), flame control

anomaly

02

Fan anomaly

03

Generic boiler P.C.B. anomaly

04

Flow probe anomaly

05

Maximum N° of reset

08

Insufficient system pressure

10

Flue pressure switch failure

11

Storage tank probe anomaly

12

Configuration error

15

Parasite flame

20

Push button control panel

anomaly

24

Insufficient circulation

27

Loss of remote control

communication.

31

Low power supply voltage

37

Loss of flame signal

38

Block due to loss of

continuous flame signal

43

Attention:

the Anomaly can be reset 5 times

consecutively, after which the function in

inhibited for at least one hour. One attempt is

gained every hour for a maximum of 5 attempts.

By switching the appliance on and off the 5

attempts are re-acquired.

Ignition block.

The boiler ignites automatically

with each demand for room heating or hot

water production. If this does not occur within

10 seconds, the boiler goes into ignition block

(code 01). To eliminate “ignition block” the Reset

button (1) must be pressed. On commissioning

or after extended downtime, it may be

necessary to eliminate the “ignition block”. If

this phenomenon occurs frequently, contact a

qualified technician for assistance (e.g. Immergas

After-Sales Technical Assistance Service).

Overheating thermostat block.

During normal

functioning, if a fault causes excessive overheating

internally, the boiler goes into overheating block

(code 02). After allowing to cool, eliminate the

"overtemperature block" by pressing the Reset

key (1). If this phenomenon occurs frequently,

contact a qualified technician for assistance

(e.g. Immergas After-Sales Technical Assistance

Service).

Fan anomaly.

This occurs if the fan is blocked

or if the intake or drain pipes are obstructed. If

normal conditions are restored the boiler restarts

without having to be reset. If this anomaly

persists, contact a qualified technician for

assistance (e.g. Immergas After-Sales Service).

Generic boiler P.C.B. anomaly.

This happens

when a signal is incorrectly recognised by

the boiler P.C.B. microprocessor (code 04).

To eliminate “boiler P.C.B. generic anomaly

block” the Reset button (1) must be pressed. If

this phenomenon occurs frequently, contact a

qualified technician for assistance (e.g. Immergas

After-Sales Technical Assistance Service).

Delivery probe anomaly.

If the board detects

an anomaly on the delivery probe (code 05),

the boiler will not start; contact a qualified

technician for assistance (e.g. Immergas After-

Sales Technical Assistance Service).

Maximum N° of reset.

Number of allowed resets

that have already been used.

Insufficient system pressure.

Water pressure

inside the heating system (code 10), sufficient to

guarantee the correct functioning of the boiler,

is not detected. Check that the system pressure

is between 1÷1.2 bar.

Flue gas pressure switch failure.

It occurs in

the case of an error on the circuit board that

gives consent for fan start-up incorrectly or

in the case of flue-gas pressure switch fault

(code 11). If normal conditions are restored the

boiler restarts without having to be reset. If this

anomaly persists, contact a qualified technician

for assistance (e.g. Immergas After-Sales Service).

Storage tank probe anomaly.

If the board detects

an anomaly a the storage tank probe (code 12),

the boiler cannot produce domestic hot water.

A qualified technician must be called (e.g. Im-

mergas After-Sales Service).

Summary of Contents for MINI NIKE X 24 3 E

Page 1: ...MINI EOLO X 24 3 E Instruction and recommendation booklet IE 1 038775ENG ...

Page 2: ......

Page 28: ...28 3 5 4 4 5 6 6 d d c INSTALLER USER MAINTENANCE TECHNICIAN ...

Page 33: ......

Page 34: ......

Page 35: ......