24

INS

TALLER

U

SER

M

AINTEN

AN

CE

TECHNI

CI

AN

TECHNI

CAL

D

AT

A

1.15 CONCENTRIC HORIZONTAL KIT

INSTALLATION

Type C configuration, sealed chamber and fan assisted

The position of the terminal (in terms of distances from openings,

overlooking buildings, floor, etc.) must be in compliance with the

regulations in force.

This terminal is connected directly to the outside of the building

for air intake and flue gas exhaust.

The horizontal kit can be installed with the rear, right side, left side

or front outlet.

For installation with frontal outlet, one must use the fixing plate

and a concentric bend coupling in order to ensure sufficient space

to carry out the tests required by law upon commissioning.

External grid

Both the Ø 60/100 and Ø 80/125 intake/exhaust terminal, if pro-

perly installed, is pleasant to look at on the outside of the building.

Make sure that the external silicone wall sealing plate is properly

inserted in the wall.

For correct functioning of the system the terminal with

grid must be installed correctly ensuring that, the "high"

indication present on the terminal is respected on in-

stallation.

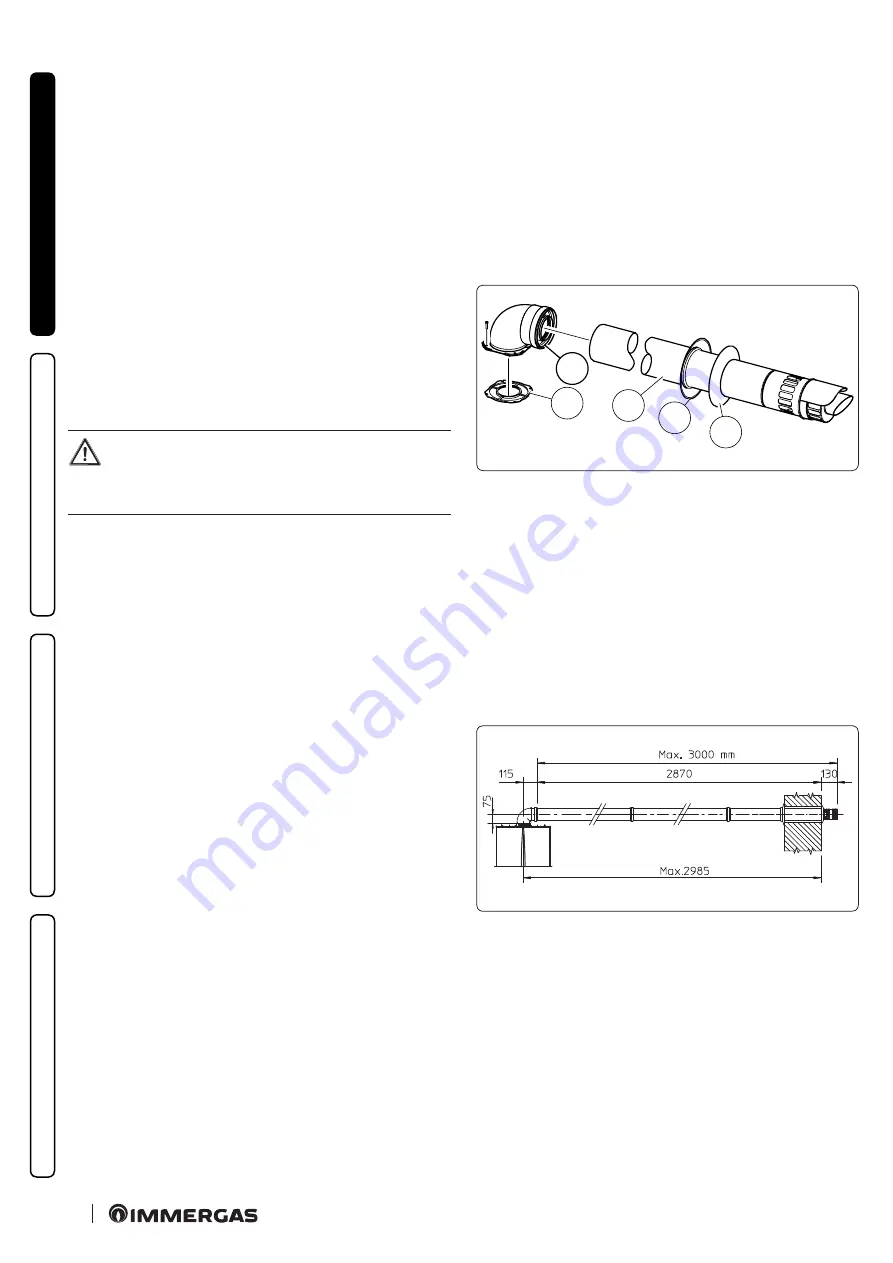

Mounting the horizontal intake-exhaust kit Ø 60/100

(Fig. 18)

1. Install the bend with flange (2) on the central hole of the boiler,

positioning gasket (1) with the circular projections

downwards in contact with the boiler flange, and tighten using

the screws present in the kit.

2. Fit the Ø 60/100 (3) concentric terminal pipe with the male

side (smooth) to the female side of the bend (2) up to the end

stop, making sure that the internal and external wall sealing

plates have been fitted; this will ensure sealing and joining of

the elements making up the kit.

C12

5

4

3

1

2

18

The kit includes (Fig. 18):

No.1 Gasket (1)

No.1 Concentric bend Ø 60/100 (2)

No.1 Int./exhaust concentric terminal Ø 60/100 (3)

No.1 Internal wall sealing plate (4)

No.1 External wall sealing plate (5)

Extensions for Ø 60/100 horizontal kit. Kit assembly (Fig. 19)

The kit with this configuration can be extended up to a max. hori-

zontal length of 3 m including the terminal with grid and exclu-

ding the concentric bend leaving the boiler.

This configuration corresponds to a resistance factor of 100.

In this case the special extensions must be requested.

C12

19