15

STNM ed 07/07

NIKE Mini Export

Technical Documentation

Technical Documentation

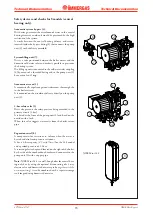

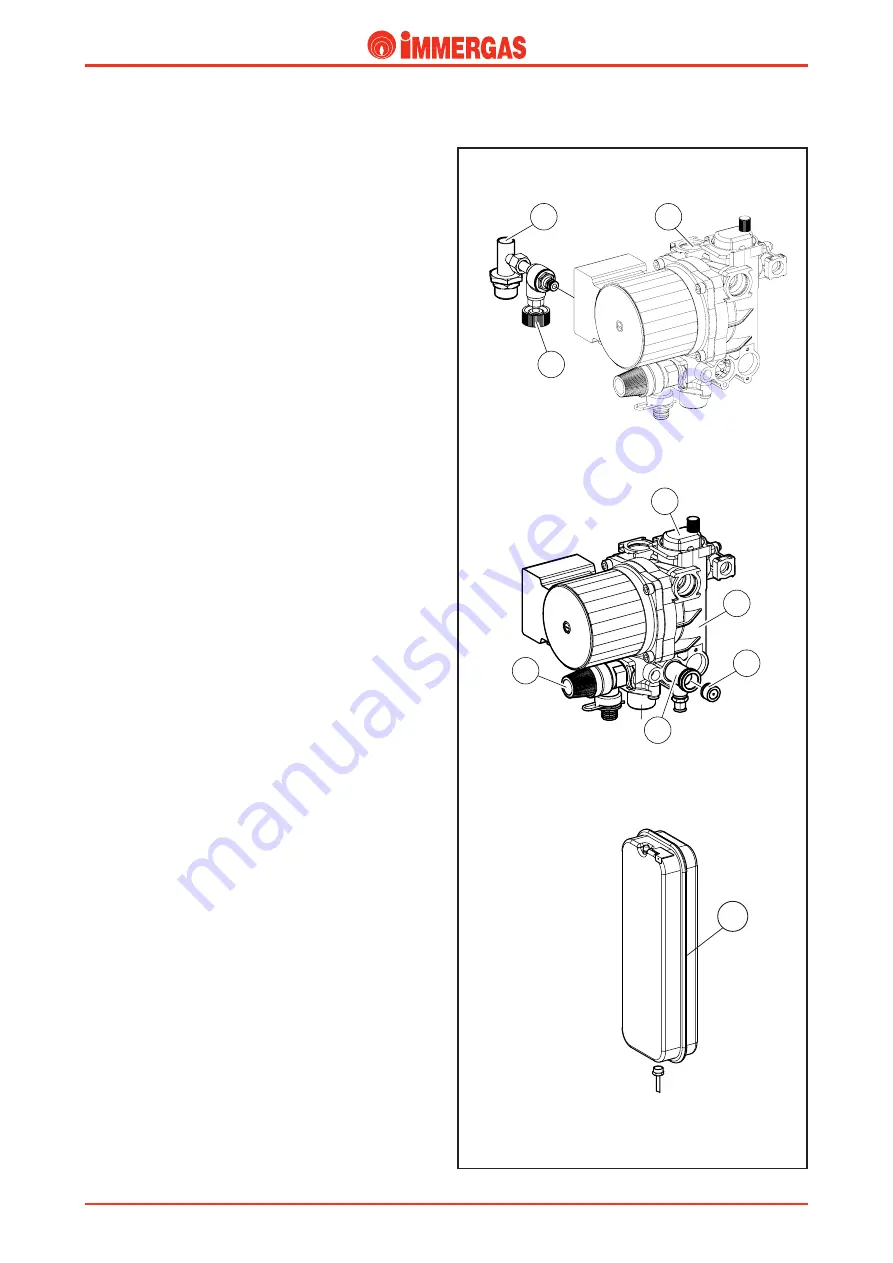

Safety devices and checks for S models (central

heating only).

Automatic system by-pass (3).

This device guarantees the circulation of water in the central

heating circuit even when it would be prevented by the high

resistance of the system.

It works between the central heating delivery and return,

inserted inside the by-pass fitting (4) that connects the pump

unit (2) to the delivery manifold.

System filling unit (7).

This is a valve positioned between the boiler circuit and the

domestic cold water inlet and makes it possible to pressurise

the heating system.

The filling up unit is connected to the cold water inlet coupling

(6) by means of a threaded fitting and to the pump unit (2)

by means of an O ring.

Automatic air vent (1).

It automatically expels any gaseous substances there might be

in the boiler circuit.

It is mounted on the circulator delivery, directly on the pump

unit (2).

3-bar safety valve (5).

This valve prevents the safety pressure being exceeded in the

primary circuit (3 bar).

It is fitted at the front of the pump unit (2) and fixed on the

outside with a fork.

When this valve triggers water exits from the boiler return

pipe.

Expansion vessel (8).

It compensates for variations in volume when the water is

heated and also limits pressure variations.

It has a 6-litre capacity

(4.5 useful litres)

for the 24 S model

and a preload pressure of 1.0 bar.

It is rectangular in shape and located on the right of the boiler,

by the side of the combustion chamber and connected to the

pump unit (2) with a copper pipe.

Note:

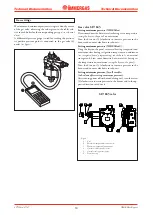

NIKE Mini 24 S is a wall-hung boiler for central heat-

ing only but by using the optional kit consisting of a 3-way

electric valve and domestic hot water probe

(together with the

necessary wiring)

, it can be combined with a separate storage

tank for producing domestic hot water.

8

4

1

2

3

5

NIKE Mini 24 S

6

7

2