9

1-7

1-8

1-9

INS

T

ALLER

US

ER

MAINTEN

AN

CE TECHNI

CI

AN

• Use and functioning.

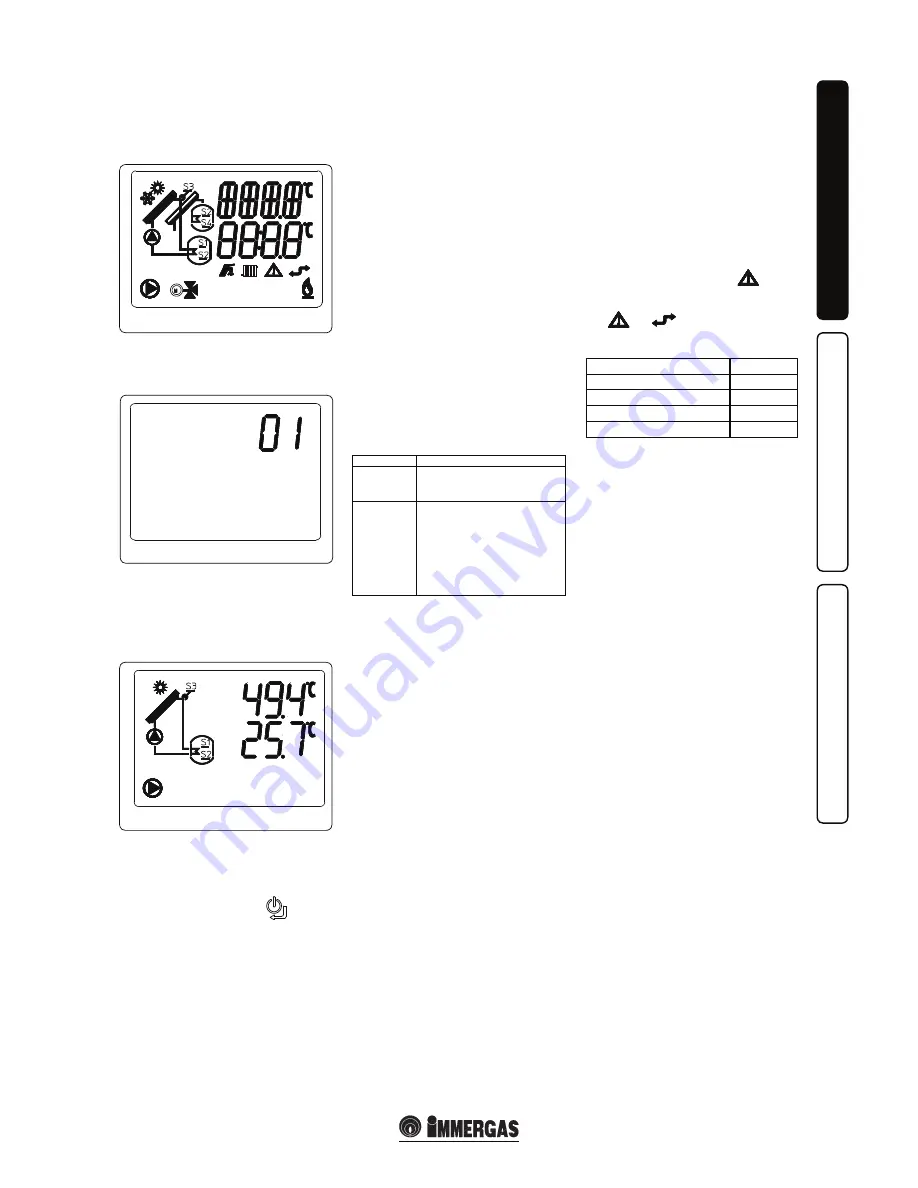

- Start-up display.

Every time power is supplied to the appliance,

the display will activate all symbols for 2

seconds:

While in the next 5 seconds, the display will

indicate the board software version:

After which, the following information

regarding the type of system will be displayed,

the temperature of the solar collector (1 ÷

170°C upper digit) and the temperature of the

storage tank probe (1 ÷ 125°C lower digit):

•

Functioning.

For the description of the parameters, refer to

the table in the previous paragraph.

-

OFF mode.

By pressing the (

) key for 3

seconds, the appliance goes to off mode (also

in the presence of anomalies). In this way, it

is not operational and the display shows off.

Only the anti-freeze protection and the pump

anti-block remain active.

- Solar pump functioning.

The pump activates and deactivates

automatically when it is set in On/Off mode.

Activation:

the solar pump will be activated

by the board if the following conditions occur

at the same time:

T tank < PAR15 – PAR16

and

Solar collector T - tank T > PAR16

D

eactivation:

the board deactivates the solar

pump if one of the following conditions

occurs:

Tank T > PAR 15

or

Solar collector T< tank T + PAR 22

Manual Functioning:

the pump can be set

in On mode (always on) or Off mode (always

off ). In the event of manual setting, the

prevention functions are inhibited.

-

Solar collector cooling function.

This

function is used to manage the pump in

the event of overheating of the solar panel

according to the following table:

Description

Condition

Solar pump

activation

PAR 15 < tank T < PAR 18

+

Solar collector T > PAR 17 - PAR 19

Solar pump

deactivation

Solar collector T (PAR 17 - PAR 19)

-1°C

or

Tank T ≥ PAR 18 +1°C

or

Solar collector T > PAR 17

(reactivates with solar collector T <

PAR17 -1°C)

With parameter 19=0, the solar collector

cooling function is deactivated; the following

conditions remain active:

Solar collector T > PAR17 => Solar pump off

Solar collector T < PAR17– 1°C => Solar

pump on

-

Cold solar collector recognition function.

The board will deactivate the solar pump

(present only with return probe) when:

Solar collector T– solar collector return T <

PAR 21

-

Solar collector anti-freeze function.

The

Solar Pump activates when:

Solar collector T < PAR 23

The board will not deactivate the solar pump

until:

Solar collector T > PAR 23 + 1°C

Important:

the default anti-freeze function

is deactivated PAR 23=0.

-

Solar pump anti-block function.

After 24

hours of inactivity, the system pumps are

activated for 3 seconds.

-

Diverter valve anti-block function.

After 24

hours of inactivity, the diverter valve will be

activated for 5 seconds (in the systems where

the diverter valve is present).

-

Priority solar function.

The function is

active when:

DHW inhibition probe T (PAR 31 - PAR 33)

< DHW set (parallel integration).

DHW inhibition probe T (PAR 31 - PAR 33)

< DHW set (priority integration) and solar

loading pump in off for a time > 5 minutes.

• Anomalies

The following table describes the possible

anomalous conditions that will be displayed on

the basis of the system ration selected.

The possible functioning error conditions are

displayed on the user interface display.

If an anomaly should occur, the (

) symbol

starts to flash as well as the back light (anomaly).

If a no communication anomaly should occur,

the (

) + (

) symbols start to flash as

well as the back light (communication anomaly).

Description of anomaly

Fault code

S1 NTC sensor fault

81

S2 NTC sensor fault

82

S3 T1000 sensor fault

83

Solar pump off

87

- Anomaly 81 NTC sensor fault: the sensor

fault, intended as a short circuit or open circuit

causes the deactivation of the Solar Pump

(active system protection). The protection is

deactivated immediately when this fault is

resolved.

- Anomaly 82 NTC sensor fault: the sensor

fault, intended as a short circuit or open circuit

causes the deactivation of the Solar Pump

(active system protection). The protection is

deactivated immediately when this fault is

resolved.

- Anomaly 83 PT1000 sensor fault: the sensor

fault, intended as a short circuit or open circuit

causes the deactivation of the Solar Pump

(active system protection). The protection is

deactivated immediately when this fault is

resolved.

- Solar pump Off: the solar control unit signals

that the solar pump is in forced Off mode

(parameter 24).

• Technical data.

Power Supply: ................... 230 Vac + 10% ÷ 15%

Frequency: ...........................................50 Hz ±5%

Mains (PF1): .......................3.15 AF (rapid) 5x20

Free contact outputs: .................5A 30 Vdc relay,

10 A 250 Vdc

(Maximum charge allowed: 0.25 A 230 Vac)

Summary of Contents for UB INOX SOLAR 200-2

Page 1: ...UB INOX Solar 200 2 STORAGE TANK UNIT Instruction booklet and warning IE 1 033447ENG ...

Page 14: ......

Page 15: ......