1

INSTALLATION

OF THE BOILER

1.1 INSTALLATION

RECOMMENDATIONS.

Only professionally qualified heating/plumbing

technicians are authorised to install Immergas

gas appliances.

The “Victrix 115 1 I” range boilers can be in-

stalled outdoors or in a suitable place (heating

control unit).

The installation must respond to the provisions

of the regulations and all laws and Standards in

force that are applicable.

Important:

these boilers are designed exclusively

for wall installation.

These boilers must be used for heating rooms

and similar.

These boilers are used to heat water to a tempe-

rature lower that boiling point at atmospheric

pressure. Therefore, they must be connected to

a heating plant that is suitable for their perfor-

mance and their power.

Before installing the appliance, ensure that it is

delivered in perfect condition; if in doubt, contact

the supplier immediately.

Packaging materials (staples, nails, plastic bags,

polystyrene foam, etc.) constitute a potential

hazard and must be kept out of the reach of

children.

Keep all flammable objects away from the ap-

pliance (paper, rags, plastic, polystyrene, etc.).

In the event of malfunctions, faults or incorrect

operation, turn the appliance off immediately and

contact a qualified technician (e.g. the Immergas

After-Sales Assistance centre, which has specifi-

cally trained staff and original spare parts).

Do not attempt to modify or repair the appliance

alone.

Failure to comply with the above implies personal

responsibility and invalidates the warranty.

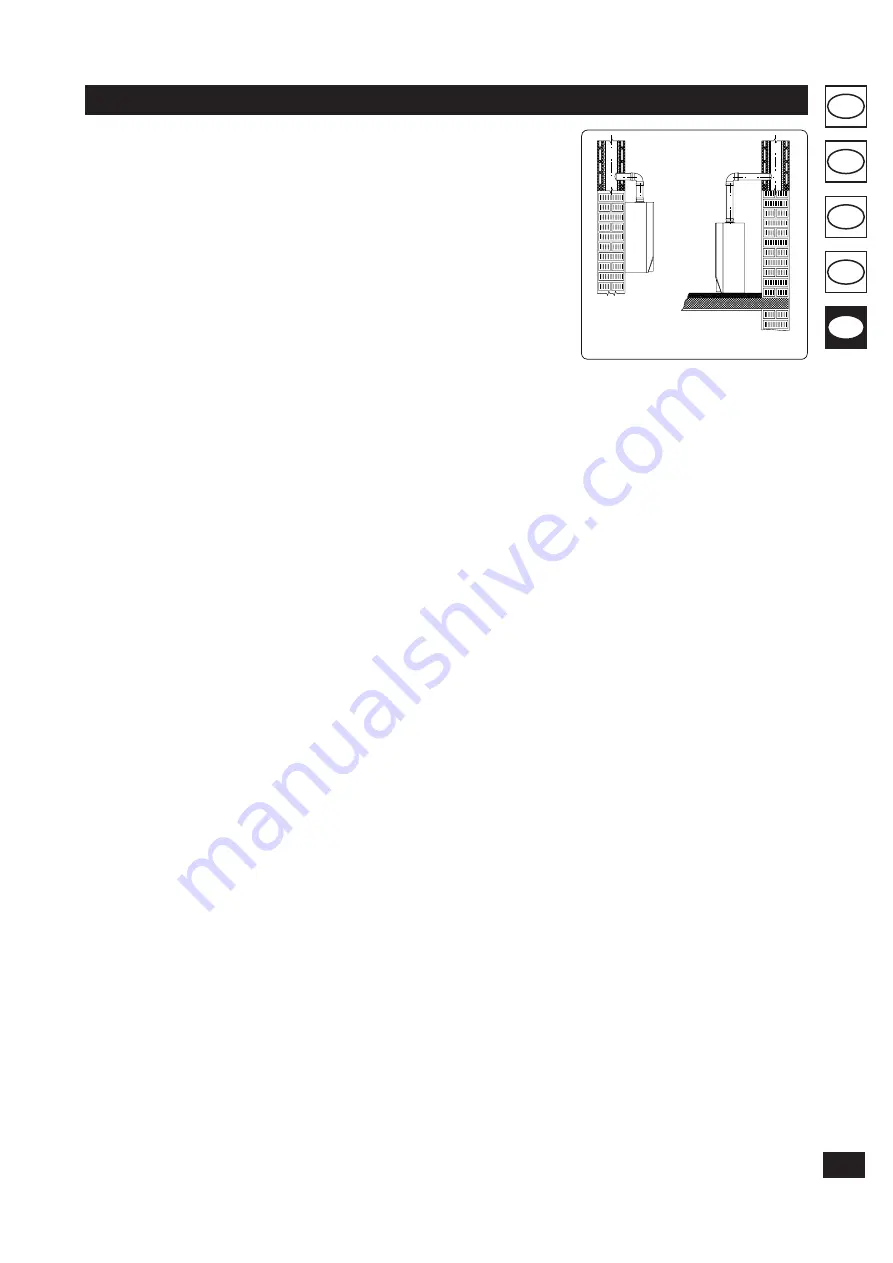

• Installation regulations: these boilers have

not been designed to be installed on plinths

or floors (Fig. 1-1), but for wall installation.

The wall surface must be smooth, without any

protrusions or recesses enabling access to the

rear part. Wall mounting of the boiler must

guarantee stable and efficient support for the

generator.

The plugs (standard supply) are to

be used only in conjunction with the mounting

brackets or fixing template to fix the appliance to

the wall

; they only ensure adequate support if

inserted correctly (according to technical stan-

dards) in walls made of solid or semi-hollow

brick or block. In the case of walls made from

hollow brick or block, partitions with limited

static properties, or in any case walls other than

those indicated, a static test must be carried out

to ensure adequate support. The boilers must

be installed in a way to prevent collisions and

tampering.

N.B.: the hex head screws supplied in the blister

pack are to be used exclusively to fix the relative

mounting bracket to the wall.

1.2 POSITION OF THE APPLIANCES.

The “Victrix 115 1 I” range boilers can be in-

stalled:

- outdoors;

- in outdoor places, also adjoining the building

served, located in a covered space, as long a

structurally separated and without walls in

common, or situated on the flat covering of

the building served, always without walls in

common;

- in building also destined for other use or in

places inserted in the volume of the building

served.

These places must be destined exclusively for

heating plants.

Important:

the installation of appliances po-

wered with gas with a greater density than 0.8

(L.P.G.) is only allowed in places out of the

ground, also communicating with places that are

on the ground. In both cases the walkway must

not have hollows or depressions such to create gas

pockets that determine dangerous conditions.

Height of the installation room.

Installation of an individual appliance

: the mini-

mum height of the room must be 2 m.

Installation of several appliances in cascade (2 or

3 Victrix 115 1 I):

considering the dimensions

of the boiler, the flue collector (to install with

gradient of 3%) and hydraulic manifolds, the

minimum height of the room must be 2.30 m.

The above-mentioned heights allow the correct

installation of the appliances.

Position of the appliances in the room.

Individual appliance

: the distances between any

external point of the boiler and the vertical, hori-

zontal walls of the room must allow accessibility

to the regulation, safety and control elements for

routine maintenance.

Several appliances, not connected to each other, but

installed in the same room:

the minimum distance

to maintain between several boilers installed

on the same wall must be 200 mm, in order to

allow accessibility to the regulation, safety and

control elements and routine maintenance of all

appliances installed

Installation in cascade (2 or 3 Victrix 115 1 I):

see

the indications supplied in par. 1.13.

1.3 AERATION AND VENTILATION OF

THE INSTALLATION ROOMS.

The rooms must have one or more permanent

openings for aeration on external walls. The

openings used for aeration can be protected using

metal grills, meshes and/or rain-proof fins as long

as the net aeration surface is not reduced.

The aeration openings must be realised and located

in a way to prevent the formation of pockets of

gas, independently from the conformation of the

covering.

Aeration for installation in outdoor places.

The

minimum free surfaces, depending on the total

heating capacity, must not be below (the values

are rounded for excess):

a) places out of the ground (S≥Qx10).

S > 928 cm

2

for N° 1 Victrix 115 1 I individual

S > 1856 cm

2

for N° 2 Victrix 115 1 I in cascade

S > 2784 cm

2

for N° 3 Victrix 115 1 I in cascade

b) basements and underground rooms up to a height

of - 5 m from the reference surface (S≥Qx15).

S > 1392 cm

2

for N° 1 Victrix 115 1 I individual

S > 2784 cm

2

for N° 2 Victrix 115 1 I in cascade

S > 4176 cm

2

for N° 3 Victrix 115 1 I in cascade

c) underground rooms at quota between -5 m and -10 m

from the reference surface (S≥Qx20, min. 5000 cm

2

).

S > 5000 cm

2

for N° 1 Victrix 115 1 I individual

S > 5000 cm

2

for N° 2 Victrix 115 1 I in cascade

S > 5568 cm

2

for N° 3 Victrix 115 1 I in cascade.

In all cases each opening must not have a net

surface area less than 100 cm

2

.

Important:

in the case of installation of applian-

ces powered with gas with greater density than

0.8 (L.P.G.) in outdoor places, out of the ground.

at least 2/3 of the aeration surface must be rea-

lised flush with the walkway, with a minimum

height of 0.2 m.

The aeration openings must be at least 2 m for

heating capacities not exceeding 116 kW and 4.5

m for higher heating capacities, cavities, depres-

sions or openings communicating with rooms

below the walkway surface or draining ducts.

Aeration for installation in building also

destined for other use or in places inserted in

the volume of the building served.

The aeration

surface must not be less than 3000 cm

2

in the case

of natural gas and must not be less than 5000 cm

2

in the case of L.P.G..

Discharge of combustion products.

The “Victrix 115 1 I” boiler must be connected to

an individual flue with safe efficiency.

N.B.:

in the case of individual installation, “Victrix

115 1 I” can be coupled to the System for Ø 80 mm

flexible piping for condensing boilers (par. 1.12).

As an alternative, the “Victrix 115 1 I” boiler

can discharge combustion products directly to

the outside, using the relevant flue exhaust kit

described in this book (par. 1.10 and 1.11).

If the “Victrix 115 1 I” boilers are installed in cascade,

the fume manifold (supplied by Immergas) will be

connected to a correctly dimensioned and efficient

chimney (par. 1.13).

Fig. 1-1

YES

NO

IRELAND

115

TR

SI

RU

IE

CZ