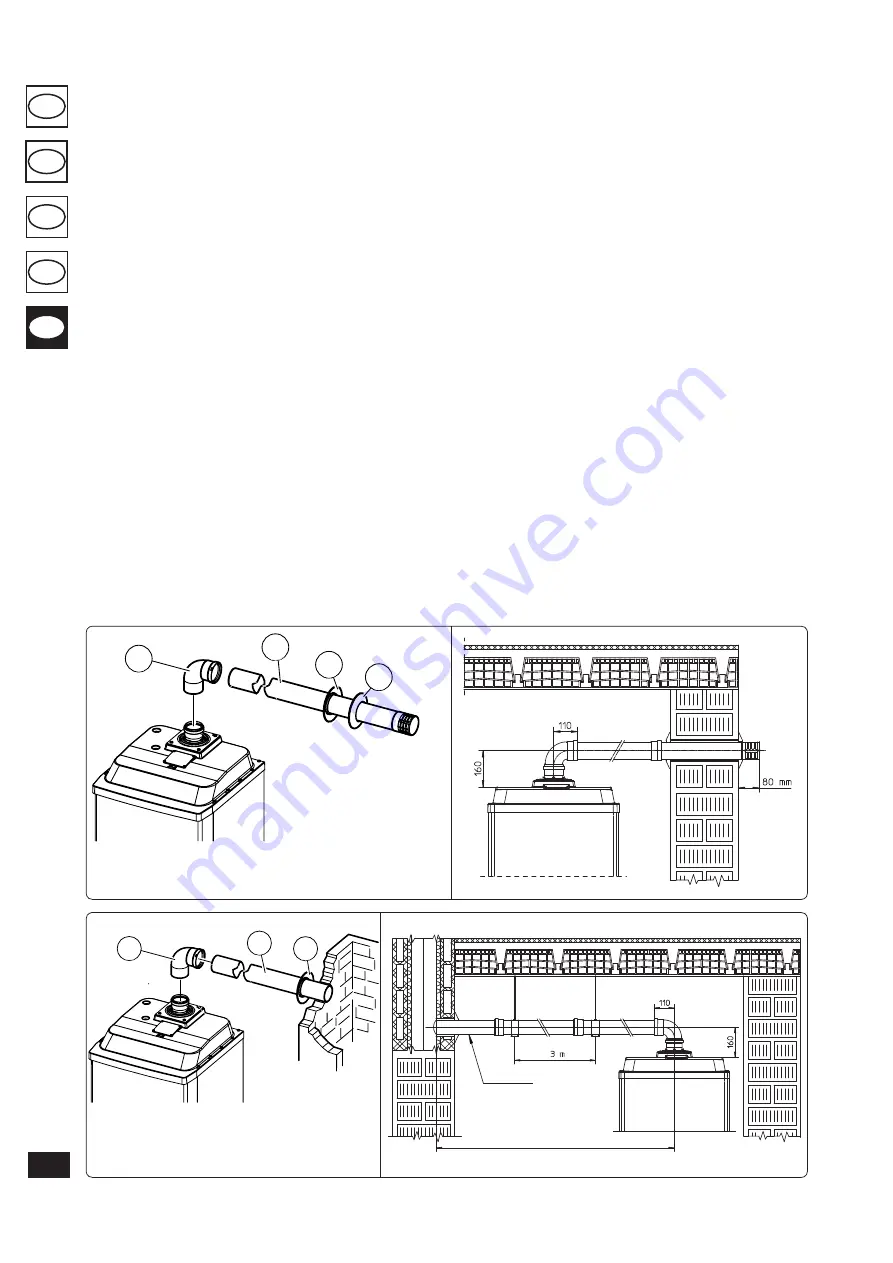

Ø 80 horizontal kit with wall flue exhaust.

Kit assembly (Fig. 1-18): install the bend Ø 80 (1)

with the male side (smooth) fully home on the

central hole of the boiler. Fit the exhaust terminal

(2) with the male end (smooth) to the female

end of the bend (1) up to the stop; making sure

that the internal (3) and external (4) wall sealing

plate has been fitted. This will ensure sealing and

joining of the elements making up the kit.

• Coupling of extension pipes and elbows. To

install push-fitting extensions with other ele-

ments of the flue extraction elements assembly,

proceed as follows: engage the pipe or elbow

with the male side (smooth) in the female

section (with lip seal) up to the stop on the

previously installed element. This will ensure

sealing efficiency of the coupling.

Horizontal kit Ø 80 with exhaust in flue.

Kit

assembly (Fig. 1-20): install the bend Ø 80 (1)

with the male side (smooth) fully home on the

central hole of the boiler. Fit the exhaust pipe (2)

with the male end (smooth) to the female end of

the bend (1) up to the stop; making sure that the

internal wall sealing plate has been fitted (3). This

will ensure sealing and joining of the elements

making up the kit.

• Coupling of extension pipes and elbows. To

install push-fitting extensions with other ele-

ments of the flue extraction elements assembly,

proceed as follows: engage the pipe or elbow

with the male side (smooth) in the female

section (with lip seal) up to the stop on the

previously installed element. This will ensure

sealing efficiency of the coupling.

• Extensions for exhaust kits. The maximum

The kit includes:

N° 1 - Bend 90° Ø 80 (1)

N° 1 - Exhaust pipe Ø 80 (2)

N° 1 - Internal wall sealing plate (3)

horizontal straight length (without bend in

exhaust), used for Ø 80 exhaust pipes is

14,5

metres

(Fig. 1-21).

N.B.:

to favour the removal of possible conden-

sate forming in the exhaust pipe, tilt the pipes

towards the boiler with a min. slope of 1.5%.

When installing the Ø 80 ducts, a section clamp

with pin must be installed every 3 metres.

1.12 DUCTING OF ExISTING FLUES.

Ducting is an operation through which, within

the context of restructuring a system and with the

introduction of one or more special ducts, a new

system is executed for evacuating the combustion

products of a gas appliance, starting from an

existing flue (or a chimney) or a technical hole.

Ducting requires the use of ducts declared to be

suitable for the purpose by the manufacturer.

Follow the installation and user instructions

provided by the manufacturer and the require-

ments of standards.

Immergas ducting system Ø 80.

The “Green

Series” Ø 80 flexible ducting system must only be

used with Immergas condensing boilers.

In any case, ducting operations must respect

the provisions contained in the standard and in

current technical regulations; in particular, the

declaration of conformity must be compiled at

the end of work and on commissioning of the

ducted system. The instructions in the project

or technical report must likewise be followed, in

cases provided for by the standard and current

technical regulations. The system or components

of the system have a technical life complying with

current standards, provided that:

- it is used in average atmospheric and envi-

ronmental conditions, according to current

regulations (absence of fumes, dusts or gases

that can alter the normal thermophysical or

chemical conditions; existence of temperatu-

res coming within the standard range of daily

variation, etc.).

- Installation and maintenance must be perfor-

med according to the indications supplied by

the manufacturer and in compliance with the

provisions in force.

- The maximum length of that the Ø 80 flexible

ducted tract can run

is equal to 17 m

. This

length is obtained considering the terminal

complete with exhaust 1m of Ø 80 pipe in

exhaust. The two 90° Ø 80 bends on boiler

outlet for connecting the ducting system and

two direction changes of the flexible pipe inside

the chimney/technical hole.

Fig. 1-18

Fig. 1-19

B23

Fig. 1-20

B23

B23

Fig. 1-21

1

4

3

2

SCARICO

1

3

2

SCARICO

The kit includes:

N° 1 - Bend 90° Ø 80 (1)

N° 1 - Exhaust terminal Ø 80

(2)

N° 1 - Internal wall sealing

plate (3)

N° 1 - External wall sealing

plate (4)

B23

min. 1,5%

MAXIM

UM LENGHT 14,5 m

122

TR

SI

RU

IE

CZ