43

STV50 ed 09/08

VICTRIX 50 Rev. 002

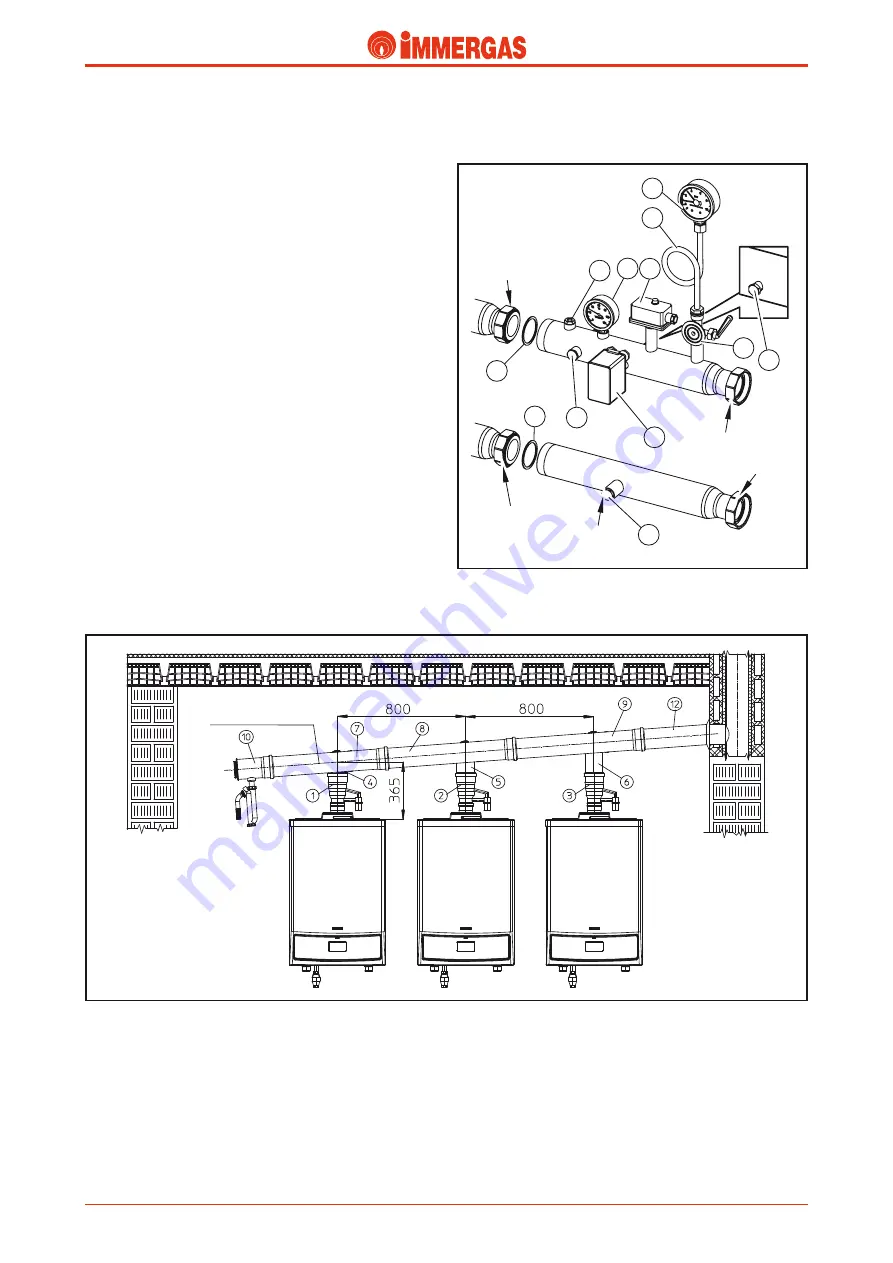

ISPESL safety devices for boilers installed in a

cascade (optional).

With this kit

(optional)

the ISPESL specifications regarding

safety in systems with powers higher than 35 kW are complied

with.

The safety devices and checks consist primarily in an ISPESL

approved thermometer (5), an ISPESL approved manually

reset thermostat (6) and an ISPESL approved manually reset

pressure switch (7).

The contacts of the thermostat (6) and pressure switch (7)

must be installed electrically in series with the boiler’s power

input.

The stub pipes, which are part of the kit, are connected di-

rectly to the boiler’s flow and return manifolds with threaded

elements and, just like the original Immergas hydraulic ma-

nifolds, these too can be installed with the output facing the

right or left.

On the system flow stub pipe it is also possible to mount a

thermometer holder housing device (2) and a probe for the

gas shut-off valve (3). The kit also includes an ISPESL type

approved manometer holder cock element (4) and a ISPESL

approved manometer (11), complete with water hammer

reducing loop (10).

The system return stub pipe, on the other hand, is set for the

connection of an expansion tank that has to be suitable for

system requirements.

Flue manifold for boilers in a cascade (optional).

G3/4"

8

G2"1/2

1

1

G2"1/2

2

5 6

4

9

G2"1/2

G2"1/2

3

7

10

11

4MPQF¡

The VICTRIX 50 boilers installed in a cascade

(battery)

in the

B

23

configuration, can be connected, by means of a manifold,

to just the one flue discharge pipe, the couple-on type,

fitted with a no-return device (damper), so that the products

of combustion of a working boiler cannot interfere with the

combustion circuit of other boilers that are off.

The system

(Green series)

is made specifically for this type of

appliance with an outside diameter of 125 mm and must lead

into an adequate flue.

The slanting angle of the 125 Ø discharge manifold must be at

least 3° and the condensate water produced by the appliances

must be made to runoff into the sewer.

The flue evacuation system cannot be installed outdoors (the

pipes must not be exposed to the ultraviolet rays of the sun).

Note:

Check, and adjust if necessary, the heat output of each

single boiler

(see handbook and instruction sheet)

.

Technical Documentation

Technical Documentation